DTC P0C14: Motor coil U-phase temperature too high

DTC P0C16: Motor coil W-phase temperature too high

DTC P0C16: Motor coil W-phase temperature too high

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Drive motor coil temperature sensor

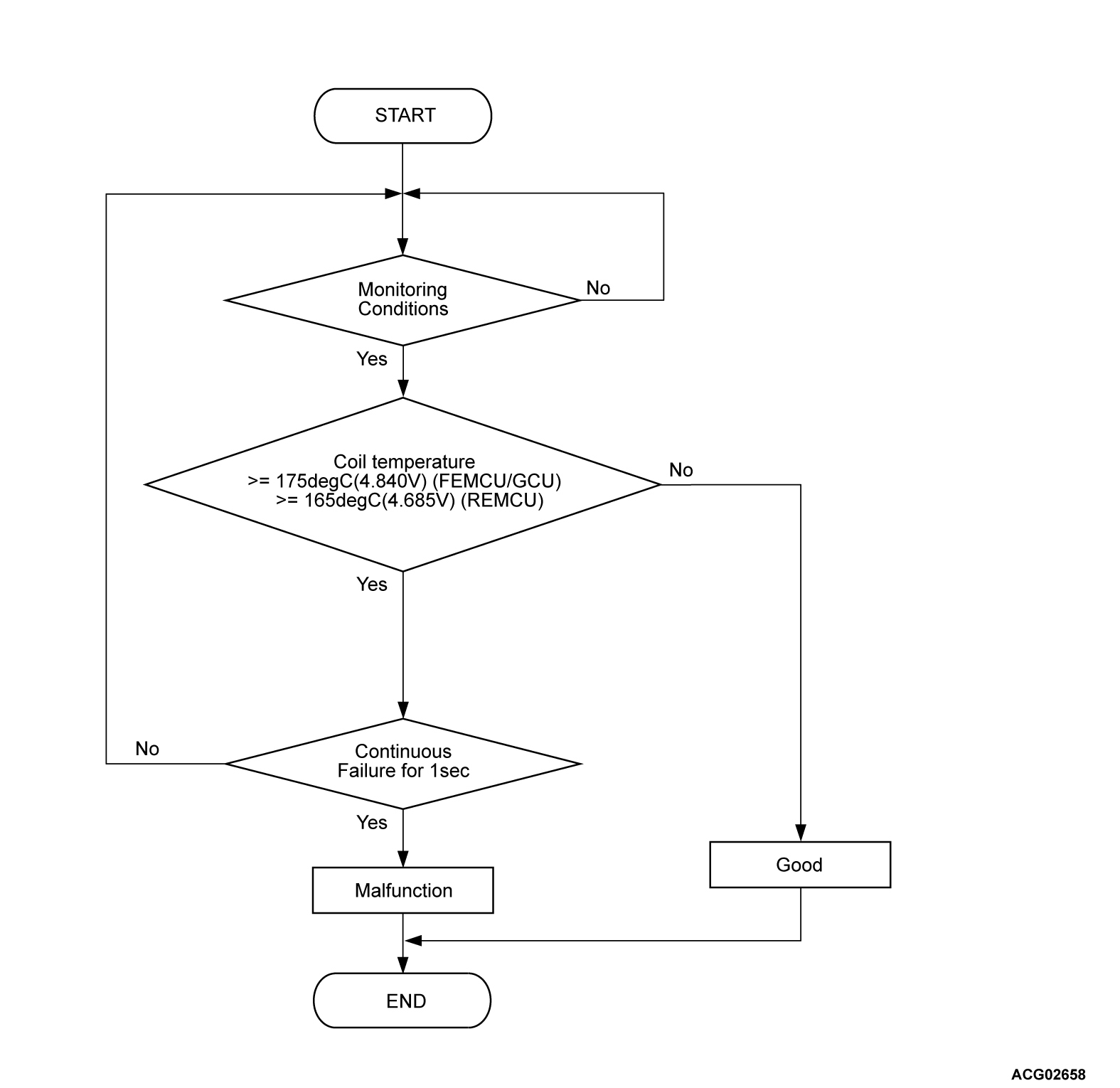

DTC SET CONDITIONS

Check Conditions

- REMCU power supply voltage is 8 volts to 16 volts.

Judgment Criterion

- Change of the coil temperature is more than 165°C (329°F) (4.685 volts) for 1 second.

PROBABLE CAUSES

- The EV cooling system fails (radiator fan, EV radiator, electric water pump)

- The temperature sensor circuit fails

- Malfunction of the rear motor/rear transaxle assembly

- Malfunction of the REMCU

DIAGNOSIS

Required Special Tools

- MB991223: Wiring harness set

- MB992006: Extra fine probe

STEP 1. Using scan tool (M.U.T.-IIISE), check whether the other DTC is set.

Check whether the PHEV-ECU set a DTC P0A05 or P10D9 which is related to the electric water pump.

Is the DTC set?

STEP 2. Using scan tool (M.U.T.-IIISE), check whether the other DTC is set.

Check whether the PHEV-ECU set a DTC P0691, P0692, P0693, P0694, P10DE or P10DF which is related to the fan, fan motor and fan shroud assembly.

Is the DTC set?

STEP 3. Check the resistance in the coil temperature sensor.

(1) Disconnect the REMCU connector.

(2) Check the conduction of the harness between the REMCU and the rear motor/rear transaxle assembly and measure the resistance value of the coil temperature sensor (U-phase and W-phase) in the REMCU connector terminals.

|

Is the check result normal?

STEP 4. Using scan tool (M.U.T.-IIISE), check the actuator test.

Check the following actuator test (Refer to GROUP 54Da - PHEV-ECU - Actuator Test Reference Table  ).

).

).

).- Item No.3: Radiator fan relay 1 actuate

- Item No.4: Radiator fan relay 2 actuate

Is the check result normal?

STEP 5. Check the EV radiator.

Visually check that the fins of the EV radiator are not dented or deformed.

Is the check result normal?

STEP 6. Check the motor coolant level.

Check that the motor coolant level is normal. (Refer to GROUP 14B - Motor Coolant Check  ).

).

).

).Is the check result normal?

STEP 7. Using scan tool (M.U.T.-IIISE), check the special function.

(1) Execute the following special function (Refer to GROUP 54Da - PHEV-ECU - Special Function, Test  ).

).

).

).- Item 2: Water pump actuate

(2) When forcibly driving the electric water pump, check that the coolant in the EV radiator condenser tank is flowing.

Is coolant flowing?

Replace the water hose and water pipe (Refer to GROUP 14B - Water Hose and Water Pipe

Replace the water hose and water pipe (Refer to GROUP 14B - Water Hose and Water Pipe  <Front>,

<Front>,  <Center>,

<Center>,  <Rear>), the electric water pump (Refer to GROUP 14B - Water Pump

<Rear>), the electric water pump (Refer to GROUP 14B - Water Pump  ), the power drive unit (Refer to

), the power drive unit (Refer to  ), the REMCU (Refer to

), the REMCU (Refer to  ), the rear motor assembly (Refer to

), the rear motor assembly (Refer to  ) and the on board charger/DC-DC converter (Refer to GROUP 54Dd - On Board Charger (OBC) /DC-DC Converter

) and the on board charger/DC-DC converter (Refer to GROUP 54Dd - On Board Charger (OBC) /DC-DC Converter  ). Then go to Step 8

). Then go to Step 8 .

.STEP 8. Using scan tool (M.U.T.-IIISE), check the special function.

(1) Execute the following special function (Refer to GROUP 54Da - PHEV-ECU - Special Function, Test  ).

).

).

).- Item 2: Water pump actuate

(2) When forcibly driving the electric water pump, check that the coolant in the EV radiator condenser tank is flowing.

Is coolant flowing?

Replace the water hose and water pipe (Refer to GROUP 14B - Water Hose and Water Pipe

Replace the water hose and water pipe (Refer to GROUP 14B - Water Hose and Water Pipe  <Front>,

<Front>,  <Center>,

<Center>,  <Rear>), the electric water pump (Refer to GROUP 14B - Water Pump

<Rear>), the electric water pump (Refer to GROUP 14B - Water Pump  ), the power drive unit (Refer to

), the power drive unit (Refer to  ), the REMCU (Refer to

), the REMCU (Refer to  ), the rear motor assembly (Refer to

), the rear motor assembly (Refer to  ) and the on board charger/DC-DC converter (Refer to GROUP 54Dd - On Board Charger (OBC) /DC-DC Converter

) and the on board charger/DC-DC converter (Refer to GROUP 54Dd - On Board Charger (OBC) /DC-DC Converter  ). Then go to Step 7

). Then go to Step 7 .

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)