DIAGNOSTIC FUNCTION

HOW TO CONNECT THE SCAN TOOL (M.U.T.-IIISE)

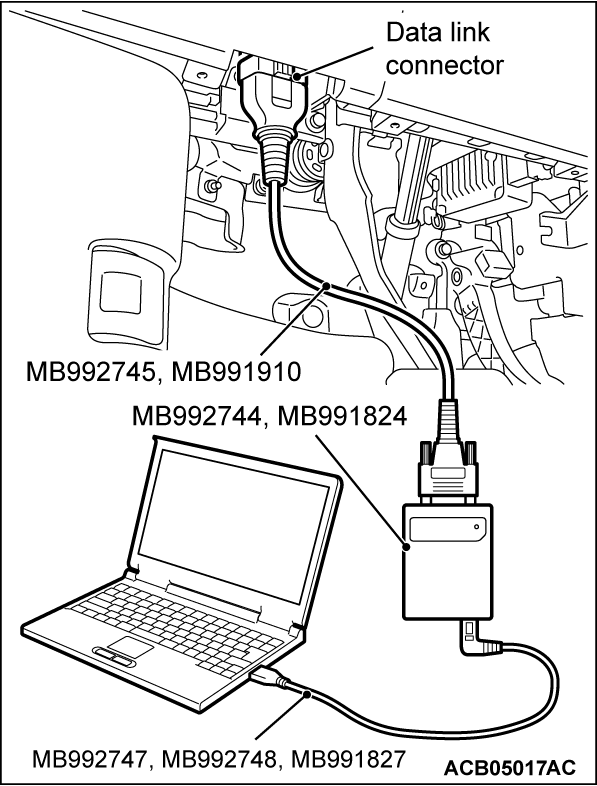

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn off the power supply mode of the electric motor switch before connecting or disconnecting scan tool (M.U.T.-IIISE). |

1. Ensure that the power supply mode of the electric motor switch should be turned off.

2. Start up the personal computer.

3. Connect special tool MB992747/M992748 or special tool MB991827 to special tool MB992744 or special tool MB991824 and the personal computer.

4. Connect special tool MB992745 or special tool MB991910 to special tool MB992744 or special tool MB991824.

5. Connect special tool MB992745 or special tool MB991910 to the data link connector.

| note | When the special tool MB992745 is connected to the data link connector, the special tool MB992744 indicator light will be illuminated in a green color. |

6. Turn the power switch of special tool MB991824 to the "ON" position. <When using the special tool MB991824>

| note | When special tool MB991824 is energized, special tool MB991824 indicator light will be illuminated in a green color. |

7. Start the M.U.T.-III system on the personal computer.

| note | Disconnecting scan tool (M.U.T.-IIISE) is the reverse of the connecting sequence, making sure that the power supply mode of the electric motor switch should be turned off. |

HOW TO READ AND ERASE DIAGNOSTIC TROUBLE CODES.

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

| note | If the 12V Starter Battery voltage is low, diagnostic trouble codes will not be set. Check the battery if scan tool (M.U.T.-IIISE) does not display. |

1. Connect scan tool (M.U.T.-IIISE) to the data link connector.

2. Turn on the power supply mode of the electric motor switch.

3. Select "STV."

4. Select "F-MCU" <FEMCU> or "GCU" <Generator control unit> or "R-MCU" <REMCU>.

5. Select "Diagnostic Trouble Code" to read the DTC.

6. If a DTC is set, it is shown.

7. Select "Erase DTCs" to erase the DTC.

HOW TO READ DATA LIST

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

1. Connect the scan tool (M.U.T.-IIISE) to the data link connector.

2. Turn on the power supply mode of the electric motor switch.

3. Select "STV."

4. Select "F-MCU" <FEMCU> or "GCU" <Generator control unit> or "R-MCU" <REMCU>.

5. Select "Data List."

6. Select an appropriate item and select the "OK" button.

HOW TO PERFORM ACTUATOR TEST

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

1. Connect the scan tool (M.U.T.-IIISE) to the data link connector.

2. Turn on the power supply mode of the electric motor switch.

3. Select "STV."

4. Select "GCU" <Generator control unit>.

5. Select "Actuator Test."

6. Select an appropriate item and select the "OK" button.

HOW TO DIAGNOSE THE CAN BUS LINES

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

1. Connect scan tool (M.U.T.-IIISE) to the data link connector.

2. Turn on the power supply mode of the electric motor switch.

3. Select "CAN bus diagnosis" from the System select screen.

4. When the optional equipment screen is displayed, choose the one which the vehicle is fitted with, and then select the "OK" button.

CHECK ON FREEZE FRAME DATA

The freeze frame data can be checked by using scan tool (M.U.T.-IIISE).

When detecting the trouble and storing the diagnostic trouble code, the ECU connected to CAN bus line obtains the data when the diagnostic trouble code is confirmed, and then stores the ECU status of that time. By analyzing each data from scan tool (M.U.T.-IIISE), the troubleshooting can be performed more efficiently. The displayed items are as the table below.

DISPLAY ITEM LIST

FEMCU

| Item No. | Item name | Unit or value |

| 1 | Odometer | km (mile) |

| 2 | Ignition cycle | - |

| 4 | Accumulated minute | min |

| 5 | Motor torque | Nm |

| 6 | Motor speed | r/min |

| 7 | Condenser voltage | V |

| 8 | Water pump fail flag | ON/OFF |

| 11 | IGBT overheating state | Normal/Over heating |

| 12 | Current DTC | No/Yes |

| 13 | Condenser discharge | Stop/Discharge |

| 14 | Ready condition(MCU) | No/Yes |

| 15 | IGCT voltage keep request | No/Yes |

| 16 | HW gate | ON/OFF |

| 17 | HW shutdown | ON/OFF |

| 18 | CPU temperature | °C (°F) |

| 19 | IGBT estimated temperature | °C (°F) |

| 20 | Condenser temperature | °C (°F) |

| 23 | Motor oil temperature | °C (°F) |

| 24 | Motor current | A |

| 25 | Motor current2 | A |

| 26 | Motor current (target: dif) | A |

| 27 | Motor current2 (target: dif) | A |

| 28 | IGBT1 temperature | °C (°F) |

| 29 | IGBT2 temperature | °C (°F) |

| 30 | Coil temperature(U) | °C (°F) |

| 31 | Coil temperature(W) | °C (°F) |

| 32 | CPU operation time | hour |

| 33 | MCU soft version | - |

| 34 | IGBT3 temperature | °C (°F) |

| 35 | Coolant water temperature | °C (°F) |

| 36 | Water pump revolution speed | r/min |

| 37 | Req. coolant water flow quantity | L |

| 38 | AD module abnormal class | No failure/15V power source/5V power source/5VA PWR monitor |

| 40 | P release shock restraint cont. | Stop/Active |

| 201 | Diagnosis state1 (High) | - |

| 202 | Diagnosis state1 (Low) | - |

| 203 | Diagnosis state2 (High) | - |

| 204 | Diagnosis state2 (Low) | - |

| 205 | Diagnosis state3 (High) | - |

| 206 | Diagnosis state3 (Low) | - |

| 207 | Diagnosis state4 | - |

GENERATOR CONTROL UNIT

| Item No. | Item name | Unit or value |

| 1 | Odometer | km (mile) |

| 2 | Ignition cycle | - |

| 4 | Accumulated minute | min |

| 5 | Motor torque | Nm |

| 6 | Motor speed | r/min |

| 7 | Condenser voltage | V |

| 8 | Water pump fail flag | ON/OFF |

| 11 | IGBT overheating state | Normal/Over heating |

| 12 | Current DTC | No/Yes |

| 13 | Condenser discharge | Stop/Discharge |

| 14 | Ready condition(MCU) | No/Yes |

| 15 | IGCT voltage keep request | No/Yes |

| 16 | HW gate | ON/OFF |

| 17 | HW shutdown | ON/OFF |

| 18 | CPU temperature | °C (°F) |

| 19 | IGBT estimated temperature | °C (°F) |

| 20 | Condenser temperature | °C (°F) |

| 21 | Oil pump output | % |

| 22 | Oil pump operating condition | % |

| 23 | Motor oil temperature | °C (°F) |

| 24 | Motor current | A |

| 25 | Motor current2 | A |

| 26 | Motor current (target: dif) | A |

| 27 | Motor current2 (target: dif) | A |

| 28 | IGBT1 temperature | °C (°F) |

| 29 | IGBT2 temperature | °C (°F) |

| 30 | Coil temperature(U) | °C (°F) |

| 31 | Coil temperature(W) | °C (°F) |

| 32 | CPU operation time | hour |

| 33 | MCU soft version | - |

| 34 | IGBT3 temperature | °C (°F) |

| 35 | Coolant water temperature | °C (°F) |

| 36 | Water pump revolution speed | r/min |

| 37 | Req. coolant water flow quantity | L |

| 38 | AD module abnormal class | No failure/15V power source/5V power source/5VA PWR monitor |

| 201 | Diagnosis state1 (High) | - |

| 202 | Diagnosis state1 (Low) | - |

| 203 | Diagnosis state2 (High) | - |

| 204 | Diagnosis state2 (Low) | - |

| 205 | Diagnosis state3 (High) | - |

| 206 | Diagnosis state3 (Low) | - |

| 207 | Diagnosis state4 | - |

REMCU

| Item No. | Item name | Unit or value |

| 1 | Odometer | km (mile) |

| 2 | Ignition cycle | - |

| 4 | Accumulated minute | min |

| 5 | Motor torque | Nm |

| 6 | Motor speed | r/min |

| 7 | Condenser voltage | V |

| 8 | Water pump fail flag | ON/OFF |

| 9 | VIN reception state | Received/Unreceived |

| 10 | IMMOBILIZER | Not supported/Supported |

| 11 | IGBT overheating state | Normal/Over heating |

| 12 | Current DTC | No/Yes |

| 13 | Condenser discharge | Stop/Discharge |

| 14 | Ready condition(MCU) | No/Yes |

| 15 | IGCT voltage keep request | No/Yes |

| 16 | HW gate | ON/OFF |

| 17 | HW shutdown | ON/OFF |

| 18 | CPU temperature | °C (°F) |

| 19 | IGBT estimated temperature | °C (°F) |

| 20 | Condenser temperature | °C (°F) |

| 24 | Motor current | A |

| 25 | Motor current2 | A |

| 26 | Motor current (target: dif) | A |

| 27 | Motor current2 (target: dif) | A |

| 28 | IGBT1 temperature | °C (°F) |

| 29 | IGBT2 temperature | °C (°F) |

| 30 | Coil temperature(U) | °C (°F) |

| 31 | Coil temperature(W) | °C (°F) |

| 32 | CPU operation time | hour |

| 33 | MCU soft version | - |

| 34 | IGBT3 temperature | °C (°F) |

| 35 | Coolant water temperature | °C (°F) |

| 36 | Water pump revolution speed | r/min |

| 37 | Req. coolant water flow quantity | L |

| 38 | AD module abnormal class | No failure/15V power source/5V power source/5VA PWR monitor |

| 201 | Diagnosis state1 (High) | - |

| 202 | Diagnosis state1 (Low) | - |

| 203 | Diagnosis state2 (High) | - |

| 204 | Diagnosis state2 (Low) | - |

| 205 | Diagnosis state3 (High) | - |

| 206 | Diagnosis state3 (Low) | - |

| 207 | Diagnosis state4 | - |

OBD- II DRIVE CYCLE

All kinds of diagnostic trouble codes (DTCs) can be monitored by carrying out a short drive according to the following 7 drive cycle patterns. In other words, doing such a drive regenerates any kind of trouble which involves illuminating the Malfunction Indicator lamp (SERVICE ENGINE SOON or Check Engine lamp) and verifies the repair procedure has been eliminated [the trouble the Malfunction Indicator lamp (SERVICE ENGINE SOON or Check Engine lamp) is no longer illuminated].| caution | Two technicians should always be in the vehicle when carrying out a test. |

| note | Check that the diagnosis trouble code (DTC) is not set before driving the OBD-II drive cycle. Erase the DTC if it has been set. |

DRIVE CYCLE PATTERN LIST

PATTERN 1

| Test procedure |

|

PATTERN 2

| Test procedure |

|

PATTERN 3

| Inspection conditions | Use scan tool (M.U.T.-IIISE) to check the BMU data list.

| ||

| Test procedure |

|

PATTERN 4

| Inspection conditions | Use scan tool (M.U.T.-IIISE) to check the BMU data list.

| ||

| Test procedure |

|

PATTERN 5

| Test procedure |

|

PATTERN 6

| Test procedure |

|

PATTERN 7

| Inspection conditions | Use scan tool (M.U.T.-IIISE) to check the BMU data list.

| ||

| Test procedure |

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)