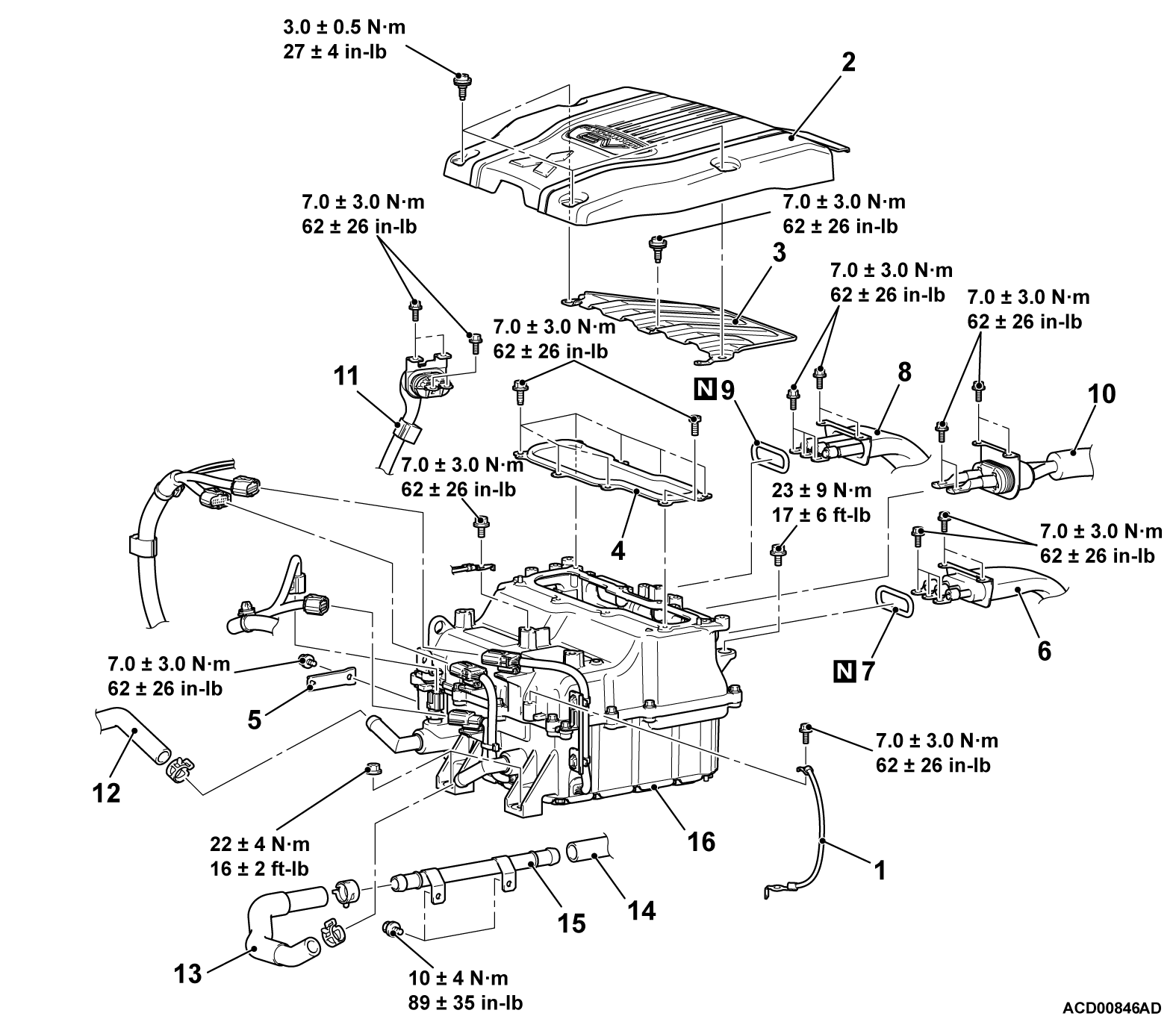

REMOVAL AND INSTALLATION

| danger | When servicing the high-voltage system parts, be sure to wear the specified protection equipment and disconnect the service plug to interrupt the high-voltage supply (Refer to  ). ). |

Pre-removal operation | Post-installation operation |

REMOVAL SERVICE POINTS

<<A>> FRONT MOTOR CABLE, GENERATOR CABLE, MAIN DRIVE LITHIUM-ION BATTERY FRONT CABLE (P, N LINE), AND AIR CONDITIONING COMPRESSOR CABLE DISCONNECTION

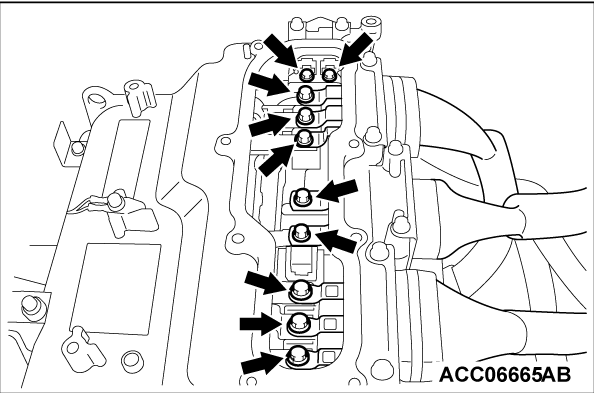

1. Remove the 10 inner cable mounting bolts.

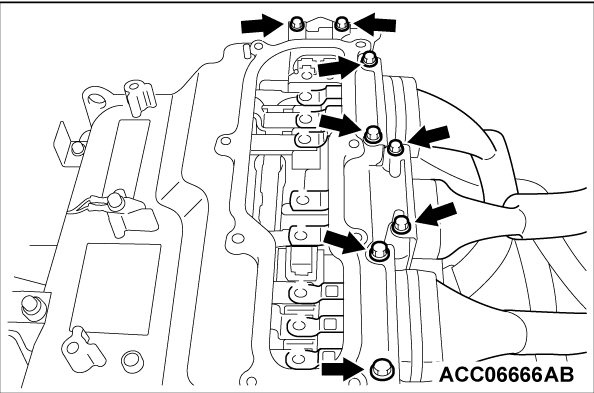

2. Remove the 8 outer cable mounting bolts.

3. Pull out the cables from the power drive unit.

INSTALLATION SERVICE POINTS

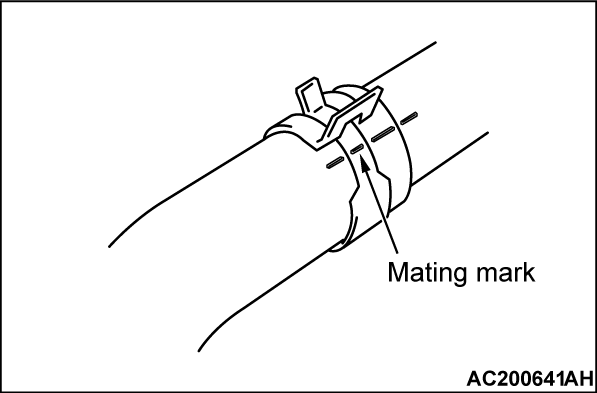

>>A<< RADIATOR PIPING HOSE CONNECTION

1. Insert the hose to each pipe up to the convex portion.

2. Align the mating marks on the hose and hose clips and install the hose without twisting the hose.

>>B<< FRONT MOTOR CABLE, GENERATOR CABLE, MAIN DRIVE LITHIUM-ION BATTERY FRONT CABLE (P, N LINE), AND AIR CONDITIONING COMPRESSOR CABLE CONNECTION

1. Connect the cables into the power drive unit.

2. Install the outer cable mounting bolts and inner cable mounting bolts in this order and tighten them to the specified torque.

Tightening torque: 7.0 ± 3.0 N·m (62 ± 26 in-lb)

>>C<< SERVICE LID INSTALLATION

| caution | When the service lid is reused, the O ring on the service lid must be free of damage (scratch or cracks). |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)