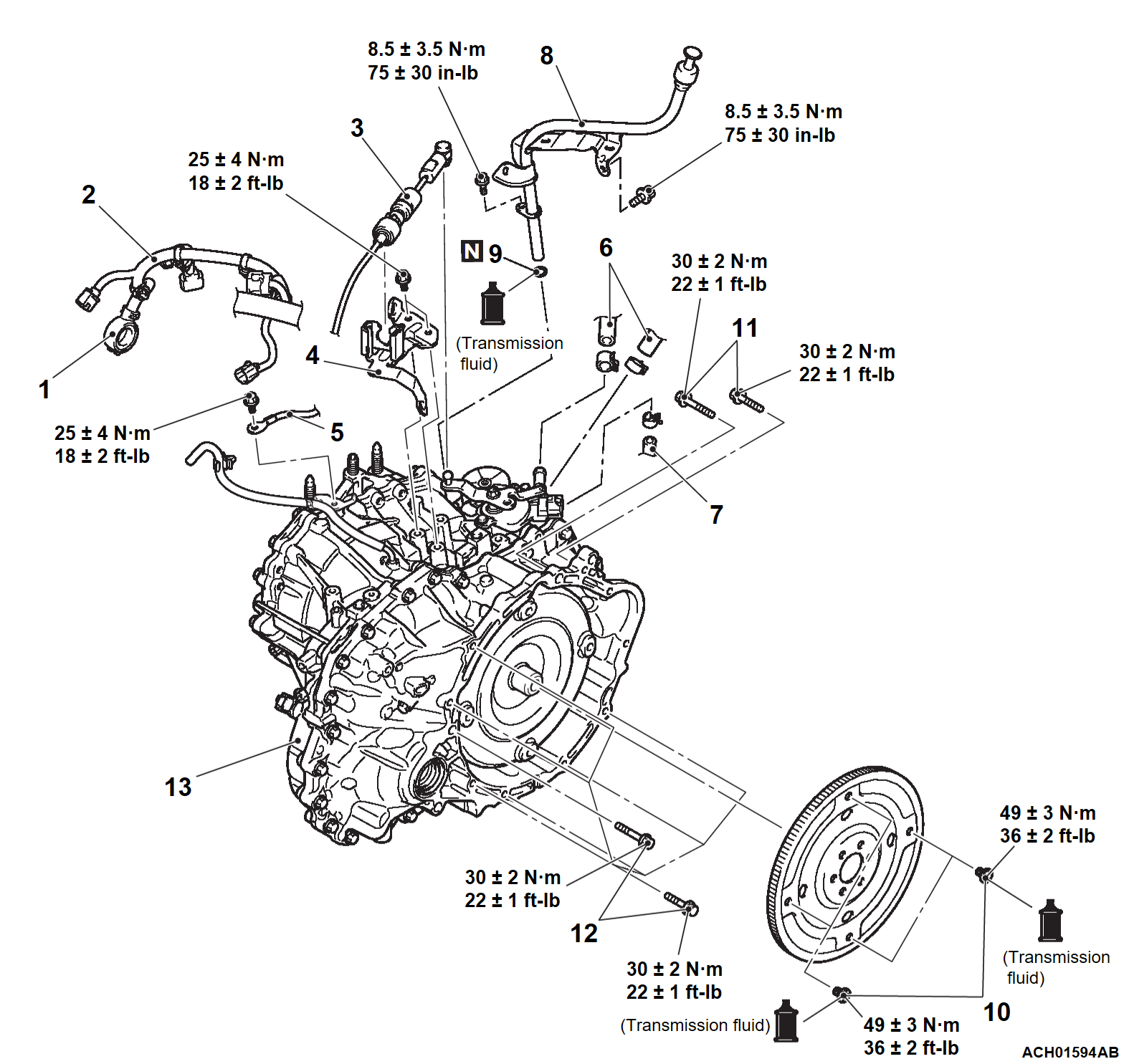

REMOVAL AND INSTALLATION

| caution |

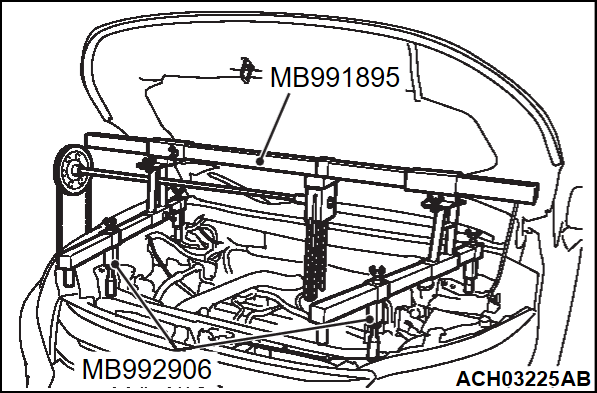

Required Special Tools:

- MB991895: Engine Hanger

- MB992277: Clip Remover

- MB992906: Engine Hanger Attachment

REMOVAL SERVICE POINTS

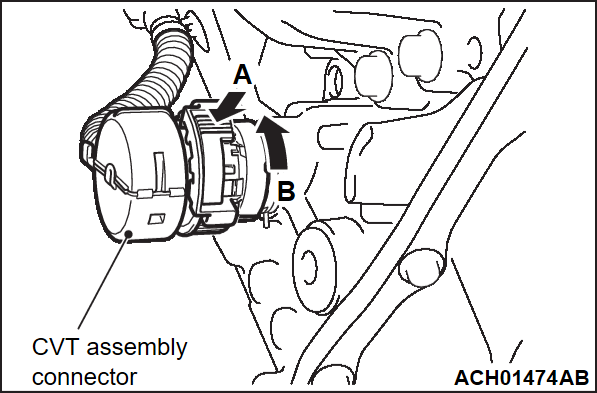

<<A>> CVT ASSEMBLY CONNECTOR DISCONNECTION

While pressing A in the figure, turn B counterclockwise to unlock the CVT assembly connector, and disconnect the connector.

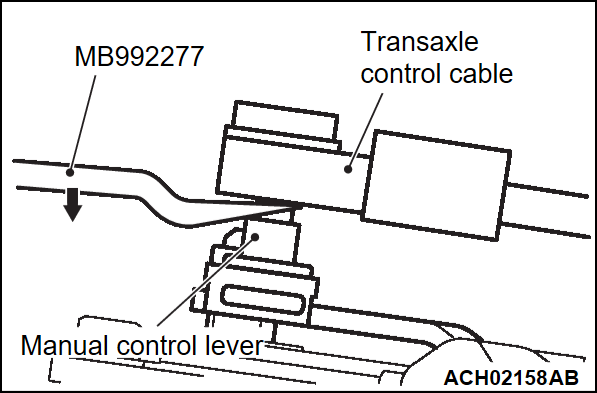

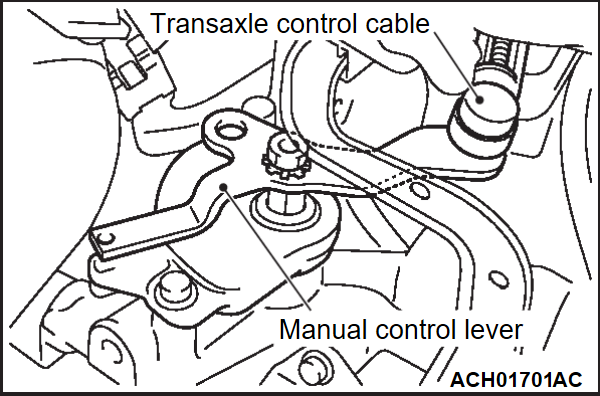

<<B>> TRANSMISSION CONTROL CABLE DISCONNECTION

1. Move the selector lever to the "N" range.

| caution | Be careful not to deform the manual control lever when disconnecting the transmission control cable. Also, do not overdo it with a slotted screwdriver etc. |

2. Insert the clip remover (Special tool: MB 992277) or a commercially available clip remover in the illustrated section between the transmission control cable and the manual control lever, and press down the tool in the direction of the arrow pressing it against the pin, and disconnect the transmission control cable by using leverage.

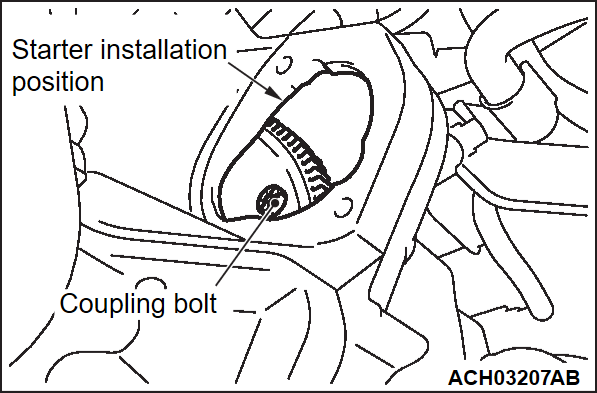

<<C>> TORQUE CONVERTER AND DRIVE PLATE COUPLING BOLT REMOVAL

Remove the coupling bolt from the starter installation section.

<<D>> ENGINE ASSEMBLY HOLDING

Hold the engine and transaxle assembly using the engine hanger (Special tool: MB991895) and engine hanger attachment (Special tool: MB992906).

| note | Slide the front foot of special tool engine hanger attachment (Special tool: MB992906) to balance the engine hanger. |

INSTALLATION SERVICE POINTS

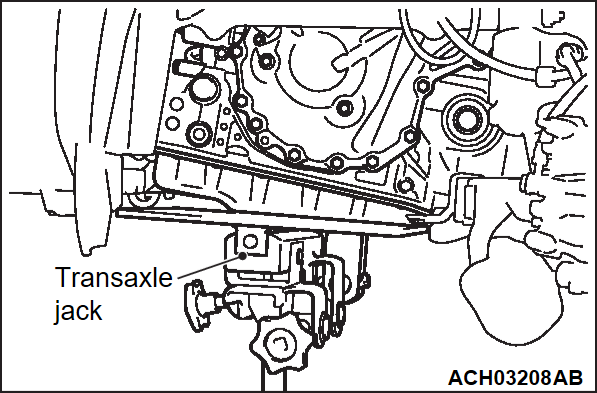

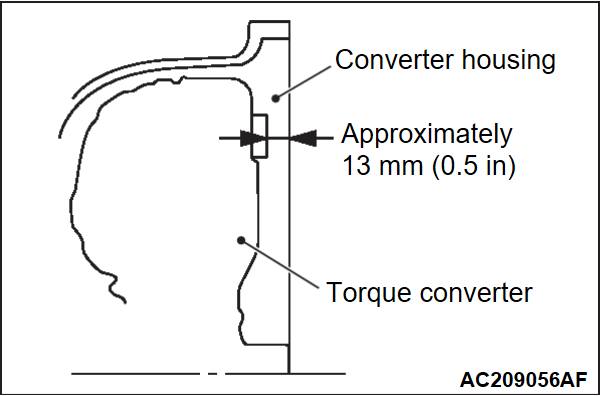

>>A<< TRANSAXLE ASSEMBLY INSTALLATION

Fully push the torque converter into the transaxle side, and then assemble the transaxle assembly to the engine.

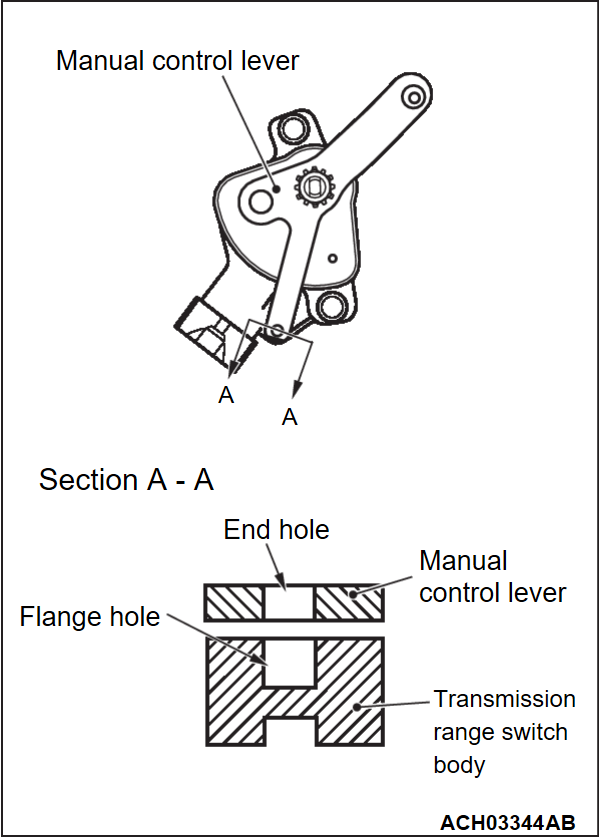

>>B<< TRANSAXLE CONTROL CABLE INSTALLATION

1. Move the selector lever to the "N" range.

2. Move the manual control lever to Neutral position.

3. Align the hole at the end of the manual control lever and the hole in the transmission range switch body flange (section A - A).

| note | Insert a Φ5 bar into the aligned holes in the transmission range switch body flange and on the tip of the manual control lever to position the transmission range switch body. |

4. Attach the transaxle control cable to the manual control lever.

5. Make sure that the transaxle side ranges that are corresponding to the selector lever position operate and function without fail.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)