DTC P0171-00: Fuel system too lean

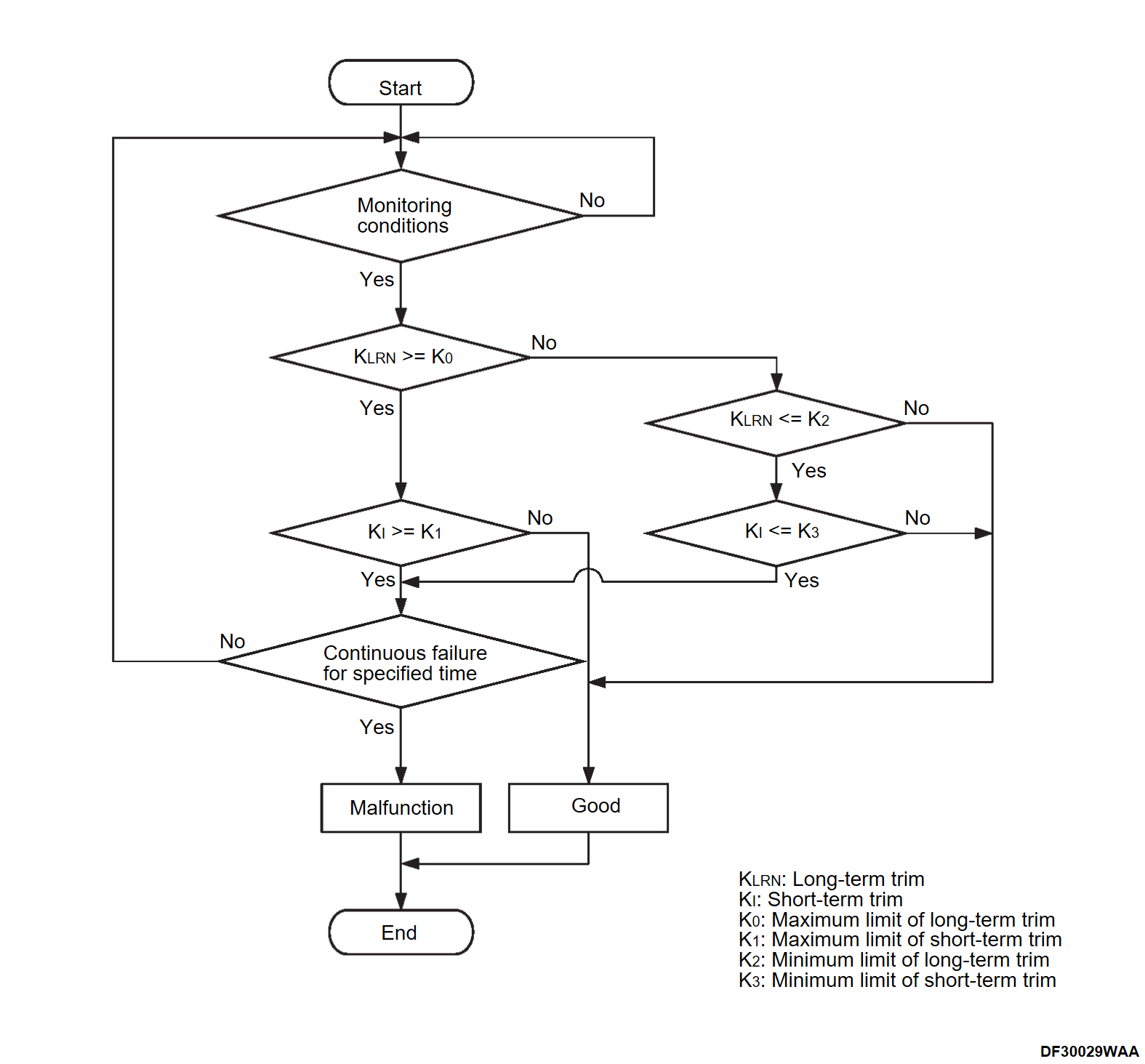

TECHNICAL DESCRIPTION

- If a malfunction occurs in the fuel system, the fuel trim value becomes too large.

- The ECM checks whether the fuel trim value is within a specified range.

DESCRIPTIONS OF MONITOR METHODS

Air-fuel learning value (long time fuel trim) and air-fuel feedback integral value (short time fuel trim) are too lean.

MONITOR EXECUTION

Continuous.

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Misfire monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Throttle position sensor

- Fuel tank pressure sensor

DTC SET CONDITIONS

Check Conditions

- Engine coolant temperature is higher than 76°C (169°F).

- Under the closed loop fuel system status.

Judgment Criterion

- Long-term fuel trim has continued to be +12.5 percent or higher for 5 seconds.

- Short-term fuel trim has continued to be +10.2 percent or higher for 5 seconds.

Check Conditions <In case of hot start>

- Engine coolant temperature is higher than 76°C (169°F).

- Under the closed loop fuel system status.

- Engine coolant temperature is higher than 100°C (212°F) when the engine is started.

- Intake air temperature is higher than 60°C (140°F) when the engine is started.

Judgment Criterion

- Long-term fuel trim has continued to be +12.5 percent or higher for 5 seconds.

- Short-term fuel trim has continued to be +20.3 percent or higher for 5 seconds.

Check Conditions

- Engine coolant temperature is higher than 76°C (169°F).

- Under the closed loop fuel system status.

Judgment Criterion

- Long-term fuel trim has continued to be +12.5 percent for 2 seconds.

- Short-term fuel trim has continued to be +25.0 percent for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

None.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 2 OBD- II DRIVE CYCLE .

.

.

.TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Linear air-fuel ratio sensor failed.

- Mass airflow sensor failed.

- Fuel injector failed.

- Incorrect fuel pressure.

- Air drawn in from gaps in gasket, seals, etc.

- Engine coolant temperature sensor failed.

- Intake air temperature sensor (built into the mass airflow sensor) failed.

- Barometric pressure sensor (built into the ECM) failed.

- Manifold absolute pressure sensor failed.

- Exhaust leak.

- Evaporative emission purge solenoid failed.

- Use of incorrect or contaminated fuel.

- fuel injector circuit harness damage or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

1.STEP 1. Using scan tool (M.U.T.-III SE), read the DTC.

Use scan tool (M.U.T.-III SE) to check and see if a DTC other than P0171-00 is set. Perform troubleshooting for the set DTC (Refer to DIAGNOSTIC TROUBLE CODE CHART

Perform troubleshooting for the set DTC (Refer to DIAGNOSTIC TROUBLE CODE CHART ).

).

Q: Is DTC other than P0171-00 set?

Perform troubleshooting for the set DTC (Refer to DIAGNOSTIC TROUBLE CODE CHART

Perform troubleshooting for the set DTC (Refer to DIAGNOSTIC TROUBLE CODE CHART ).

).2.STEP 2. Using scan tool (M.U.T.-III SE), check the data list.

Use scan tool (M.U.T.-III SE) to check the data list (Refer to DATA LIST REFERENCE TABLE ).

). Perform the DTC classified check procedure for the sensor that has shown an abnormal data value (Refer to DIAGNOSTIC TROUBLE CODE CHART

Perform the DTC classified check procedure for the sensor that has shown an abnormal data value (Refer to DIAGNOSTIC TROUBLE CODE CHART ).

).

).

).- Item number 50: Air Temperature Sensor

- Item number 60: Coolant (Water) Temperature Sensor

- Item number 70: Boost Sensor

- Item number 80: Air flow Sensor

- Item number A3301: Barometric pressure sensor

- Item number A3417: LAFS (Bank1 Sensor1)

Q: Are the check result normal?

Perform the DTC classified check procedure for the sensor that has shown an abnormal data value (Refer to DIAGNOSTIC TROUBLE CODE CHART

Perform the DTC classified check procedure for the sensor that has shown an abnormal data value (Refer to DIAGNOSTIC TROUBLE CODE CHART ).

).3.STEP 3. Check for exhaust leaks from the main catalytic converter assembly.

4.STEP 4. Check air intake from air cleaner throttle body duct and intake manifold.

5.STEP 5. Check evaporative emission purge solenoid itself.

Check evaporative emission purge solenoid itself (Refer to ENGINE, Engine, Motor and Emission Control – Emission Control – Evaporative Emission System EVAPORATIVE EMISSION PURGE SOLENOID CHECK ).

). Replace the evaporative emission purge solenoid (Refer to ENGINE, Intake and Exhaust – Intake Manifold INTAKE MANIFOLD REMOVAL AND INSTALLATION

Replace the evaporative emission purge solenoid (Refer to ENGINE, Intake and Exhaust – Intake Manifold INTAKE MANIFOLD REMOVAL AND INSTALLATION ).

).

).

).Q: Is the check result normal?

Replace the evaporative emission purge solenoid (Refer to ENGINE, Intake and Exhaust – Intake Manifold INTAKE MANIFOLD REMOVAL AND INSTALLATION

Replace the evaporative emission purge solenoid (Refer to ENGINE, Intake and Exhaust – Intake Manifold INTAKE MANIFOLD REMOVAL AND INSTALLATION ).

).6.STEP 6. Check fuel injector itself.

Check number 1, number 2, number 3, number 4 fuel injector itself (Refer to FUEL INJECTOR CHECK ).

). Replace the fuel injector (Refer to FUEL INJECTOR REMOVAL AND INSTALLATION

Replace the fuel injector (Refer to FUEL INJECTOR REMOVAL AND INSTALLATION ).

).

).

).Q: Are the check result normal?

Replace the fuel injector (Refer to FUEL INJECTOR REMOVAL AND INSTALLATION

Replace the fuel injector (Refer to FUEL INJECTOR REMOVAL AND INSTALLATION ).

).7.STEP 7. Check harness between number 1 fuel injector connector terminal number 1 and ECM connector terminal number 3.

Check output line for damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.8.STEP 8. Check harness between number 2 fuel injector connector terminal number 1 and ECM connector terminal number 4.

Check output line for damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.9.STEP 9. Check harness between number 3 fuel injector connector terminal number 1 and ECM connector terminal number 5.

Check output line for damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.10.STEP 10. Check harness between number 4 fuel injector connector terminal number 1 and ECM connector terminal number 6.

Check output line for damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.11.STEP 11. Fuel pressure measurement.

12.STEP 12. Check fuel.

Check for entry of foreign matter (water, kerosene, etc.) into fuel. Replace the fuel.

Replace the fuel.

Q: Is the check result normal?

Replace the fuel.

Replace the fuel.13.STEP 13. Test the OBD-II drive cycle.

After erasing the DTC, carry out test drive with the drive cycle pattern, and recheck the DTC. Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).

(1) Use scan tool (M.U.T.-III SE) to erase the DTC.

(2) Carry out test drive with the drive cycle pattern (Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 2 OBD- II DRIVE CYCLE ).

).

).

).(3) Use scan tool (M.U.T.-III SE) to recheck the DTC.

Q: Is DTC P0171-00 set?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)