REMOVAL AND INSTALLATION

| caution | When the fuel injector is replaced, initialise the learned value using scan tool (M.U.T.-III SE) (Refer to Initialisation Procedure for Learning Value in MFI Engine INITIALISATION PROCEDURE FOR LEARNING VALUE IN MFI ENGINE ). ). |

Pre-removal operation

- Fuel Line Pressure Reduction (Refer to FUEL PUMP CONNECTOR DISCONNECTION (HOW TO REDUCE PRESSURIZED FUEL PRESSURE)

).

). - Air conditioning sensor connector/Front connector Braket Removal (Refer to Intake/Exhaust - AIR CLEANER REMOVAL AND INSTALLATION

).

).

Post-installation operation

- Air conditioning sensor connector/Front connector Braket Installation (Refer to Intake/Exhaust - AIR CLEANER REMOVAL AND INSTALLATION

).

). - Fuel Leak Check.

REMOVAL SERVICE POINTS

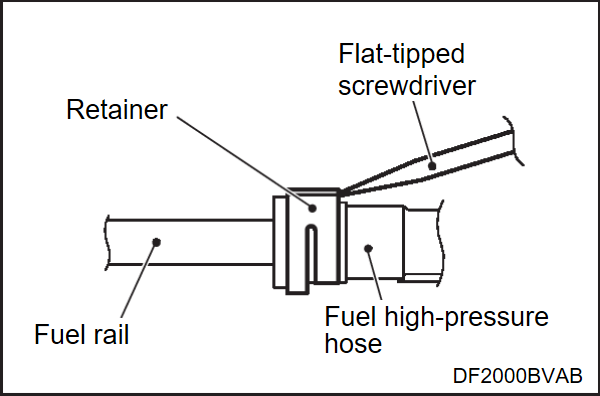

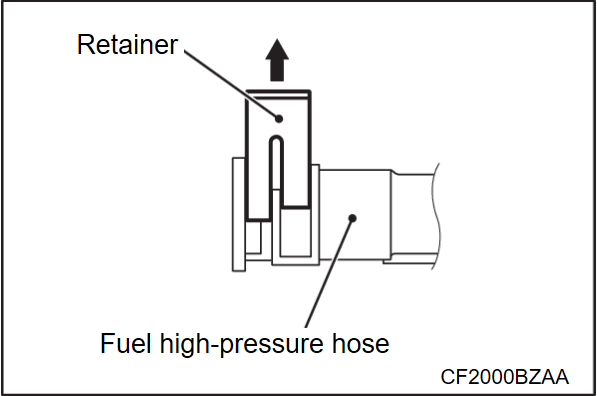

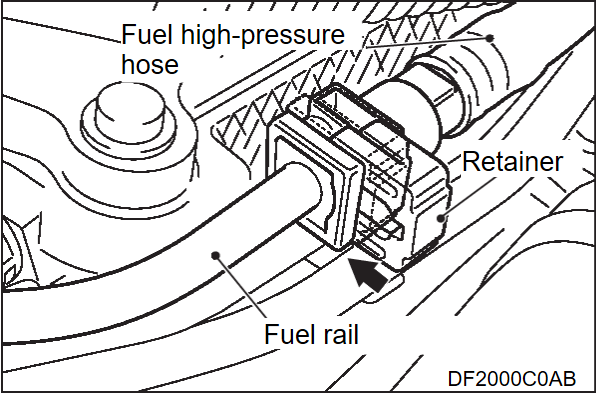

<<A>> FUEL HIGH-PRESSURE HOSE DISCONNECTION

1. Follow the steps below to unlock the fuel high-pressure hose connector.

(1) Insert a flat-tipped screwdriver [6 mm (0.24 inch) wide and 1 mm (0.03 inch) thick] into the retainer of the fuel high-pressure hose connector.

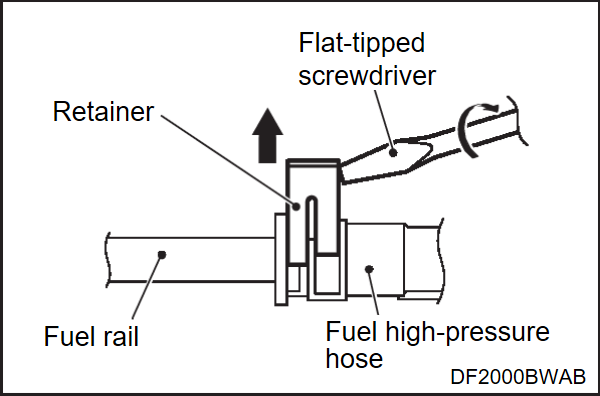

| caution | When pushing up the retainer of the fuel high-pressure hose connector, pay attention to avoid damage to the retainer. |

(2) Turn the flat-tipped screwdriver inserted into the retainer by 90 degrees to push up the retainer and unlock the fuel high-pressure hose connector.

2. Remove the fuel high-pressure hose.

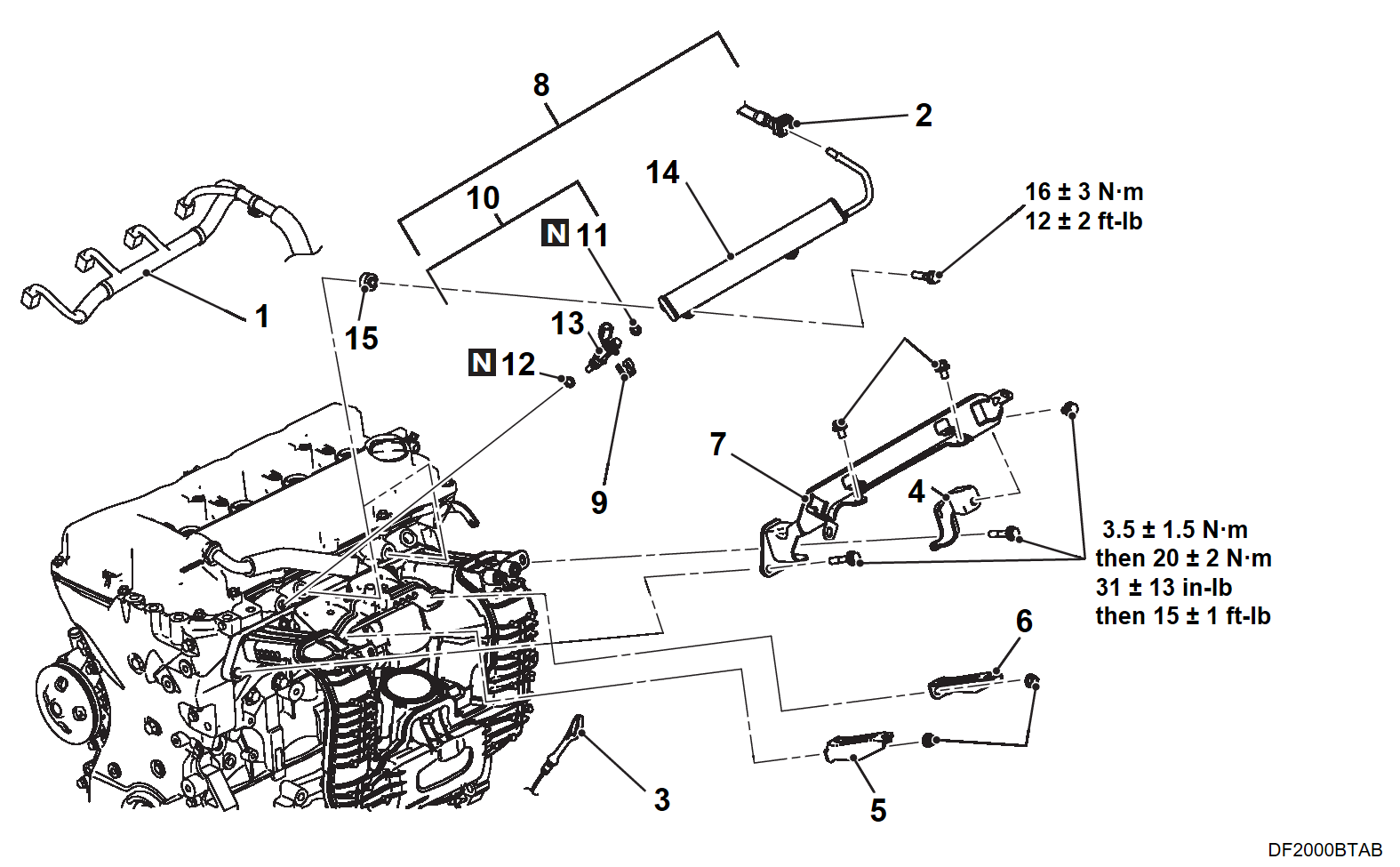

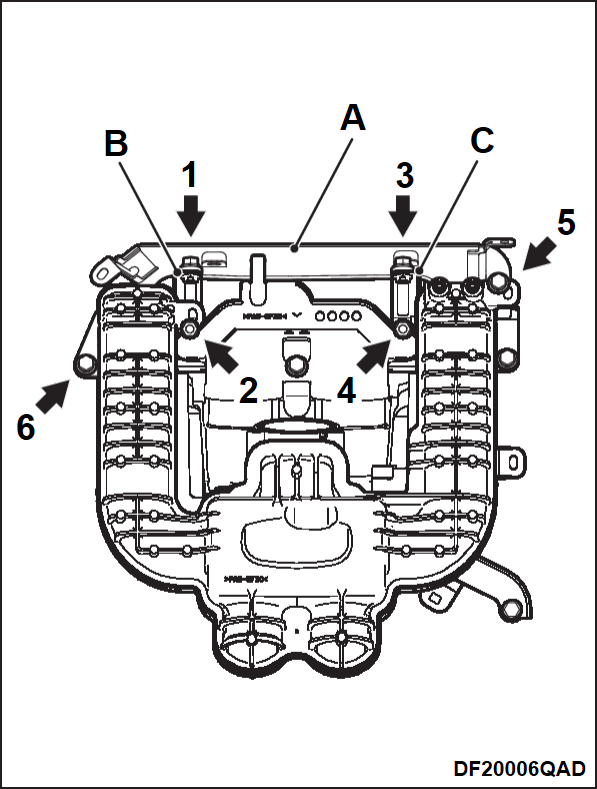

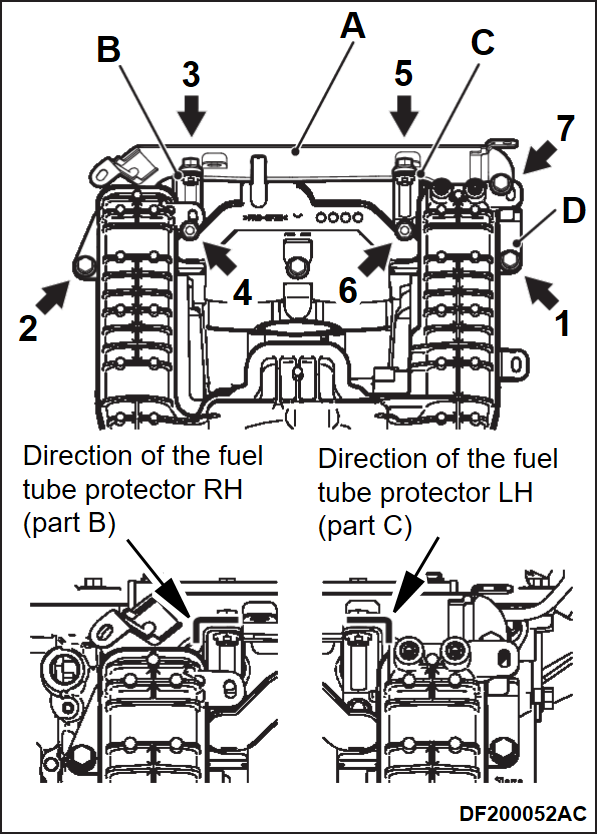

<<B>> FUEL TUBE PROTECTOR/FUEL RAIL AND FUEL INJECTOR ASSEMBLY REMOVAL

When removing the above parts, to secure the contact pressure of the intake manifold gasket, remove the Fuel Tube Protector/Fuel Rail and Fuel Injector Assembly by the following procedures.

1. Loosen bolts 1 and 2 shown in the figure, remove the fuel tube protector RH (part B), and temporarily tighten bolt 2 shown in the figure to the specified torque.

Tightening torque: 3.5 ± 1.5 N·m (31 ± 13 in-lb)

2. Loosen bolts 3 and 4 shown in the figure, remove the fuel tube protector LH (part C), and temporarily tighten bolt 4 shown in the figure to the specified torque.

Tightening torque: 3.5 ± 1.5 N·m (31 ± 13 in-lb)

3. Loosen bolts 5 and 6 shown in the figure, and remove the fuel tube protector (part A).

4. Remove the fuel rail and fuel injector assembly.

INSTALLATION SERVICE POINTS

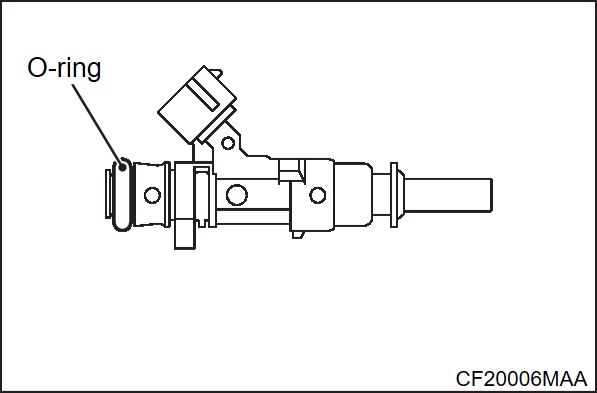

>>A<< O-RING INSTALLATION

1. Apply a small amount of petrol to the O-ring.

2. While turning the fuel injector to right and left, install the O-ring to the fuel injector with care to avoid damage to the O-ring.

>>B<< O-RING INSTALLATION

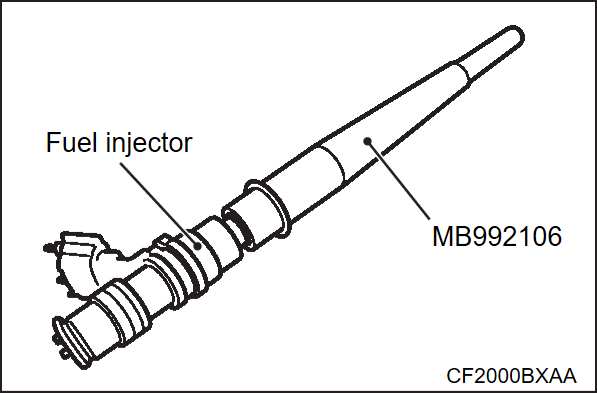

1. Apply a small amount of petrol oil to a new O-ring.

2. Using special tool O-ring installer (MB992106), install the fuel injector paying attention to avoid damage to the O-ring.

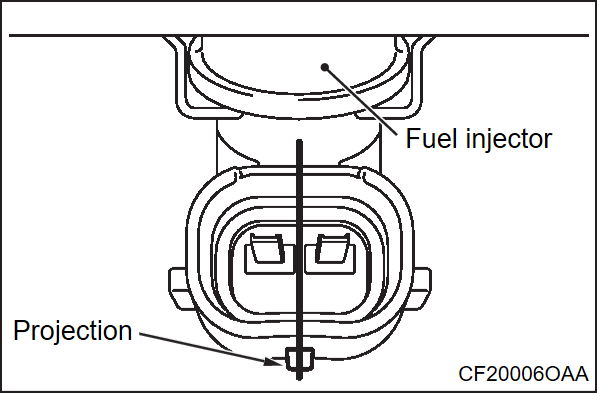

>>C<< FUEL INJECTOR ASSEMBLY INSTALLATION

1. Apply a small amount of petrol to a new O-ring.

2. Turning the fuel injector assembly to right and left, install it to the fuel rail with care not to damage the O-ring. After the installation, check for its smooth rotation. At this time, check that the projection part of the fuel injector assembly is in the center.

3. If the rotation is not smooth, the O-ring may be caught. Remove the fuel injector assembly and check the O-ring for damage. After this, re-insert it to the fuel rail and check for its smooth rotation.

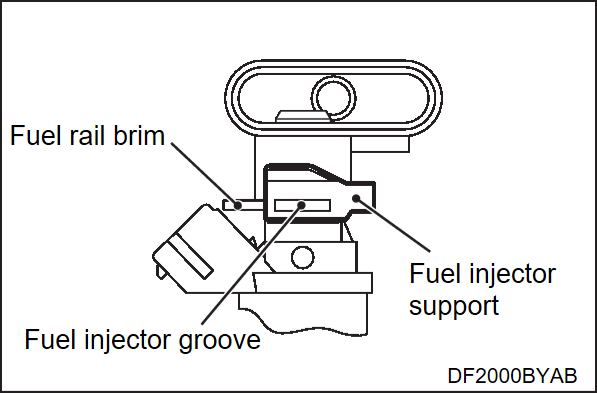

>>D<< FUEL INJECTOR SUPPORT INSTALLATION

Install the fuel injector support to the fuel injector groove and fuel rail brim, and fix the fuel injector assembly and fuel rail.

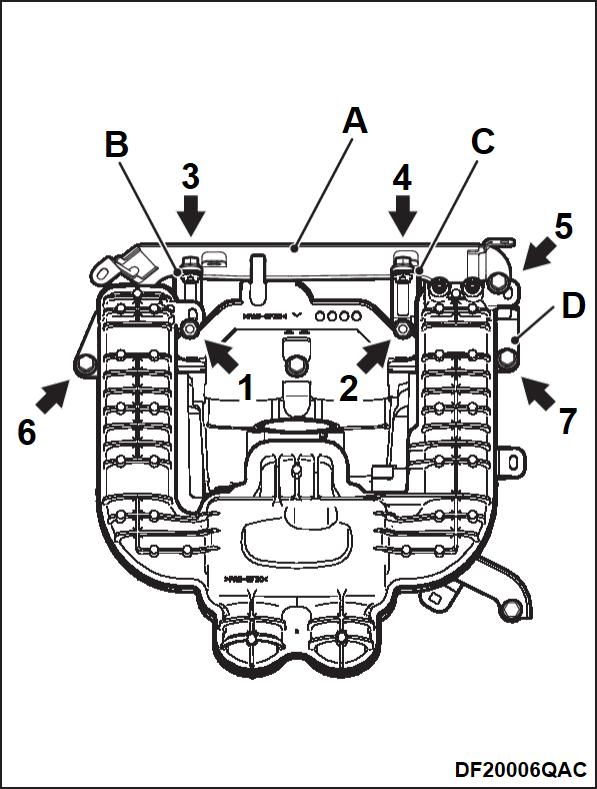

>>E<< FUEL RAIL AND FUEL INJECTOR ASSEMBLY/FUEL TUBE PROTECTOR INSTALLATION

1. Apply a small amount of petrol to the O-ring at the end of fuel injector assembly.

| caution | When installing the fuel rail and fuel injector assembly on the cylinder head, take care not to damage the O-ring at the tip of the fuel injector assembly. |

2. Tighten the fuel rail and fuel injector assembly to the specified torque.

Tightening torque: 16 ± 3 N·m (12 ± 2 ft-lb)

3. Temporarily tighten the parts A, B, C and D shown in the figure to the specified torque by the following procedure.

Tightening torque: 3.5 ± 1.5 N·m (31 ± 13 in-lb)

(1) Temporarily tighten the fuel tube protector (part D) with bolt 1 shown in the figure.

(2) Temporarily tighten the fuel tube protector (part A) with bolt 2 shown in the figure.

(3) Check that the direction of the fuel tube protector RH (part B) is as shown in the figure, and temporarily tighten bolts 3 and 4 shown in the figure.

(4) Check that the direction of the fuel tube protector LH (part C) is as shown in the figure, and temporarily tighten bolts 5 and 6 shown in the figure.

(5) Temporarily tighten the fuel tube protector (part A) and fuel tube protector stay (part D) with bolt 7 shown in the figure.

4. Tighten the mounting bolts and nuts to the specified torque in the numerical order as shown in the figure.

Tightening torque: 20 ± 2 N·m (15 ± 1 ft-lb)

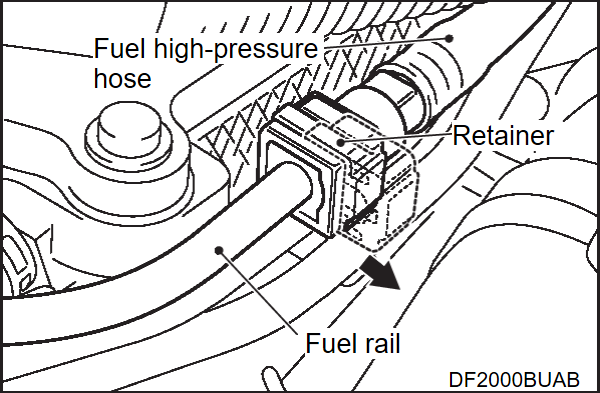

>>F<< FUEL HIGH-PRESSURE HOSE CONNECTION

1. Pull up the retainer of fuel high-pressure hose to unlock before installing.

| caution |

|

2. Pull up the retainer of fuel high-pressure hose to unlock before installing.

3. Push in the retainer of the fuel high-pressure hose connector to lock the fuel high-pressure hose and fuel rail.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)