Removal and Installation

REMOVAL

| warning |

|

| caution |

|

| note | When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling. |

Outline

Remove the engine and the transaxle assembly from the vehicle downward. Separate the engine and the transaxle.

Preparation

1. Release fuel pressure. Refer to Work ProcedureWork Flow .

.

.

.2. Drain engine coolant from radiator. Refer to Draining .

.

.

.| caution |

|

3. Remove the following parts.

- Engine cover: Refer to Removal and Installation

.

. - Battery and battery tray: Refer to Removal and Installation

.

. - Air duct and air cleaner assembly: Refer to Removal and Installation

.

. - Engine under cover front: Refer to Removal and Installation

.

. - Front road wheels and tires: Refer to Removal & Installation

.

. - Front fender protector (RH and LH): Refer to Removal and Installation

.

. - Splash guard protector (RH and LH): Refer to Removal and Installation

.

. - Exhaust front tube: Refer to Removal and Installation

.

. - Front bumper. Refer to Removal and Installation.Removal and Installation

- Front bumper reinforcement. Refer to Removal and Installation.Removal and Installation

4. Discharge refrigerant from A/C circuit. Refer to Recycle Refrigerant .

.

.

.Engine Room LH

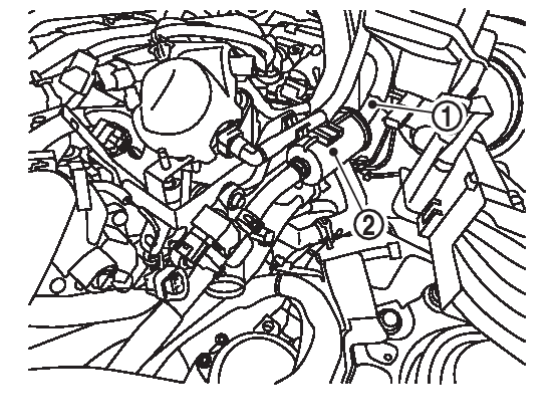

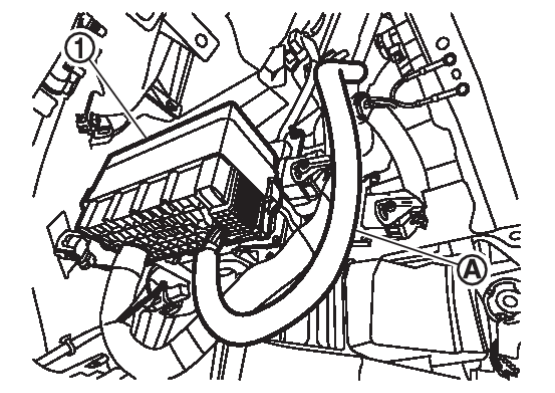

1. Disconnect all connections of engine harness around the engine mounting insulator (LH), and then temporarily secure the engine harness into the engine side.

| caution | Protect connectors using a resin bag against foreign materials during the operation. |

2. Remove battery bracket. Refer to Removal and Installation .

.

.

.3. Remove the battery positive terminal harness nut  . Refer to Removal and Installation

. Refer to Removal and Installation .

.

. Refer to Removal and Installation

. Refer to Removal and Installation .

. | : Vehicle front |

4. Disconnect the cooling fan harness connector and clamp.

5. Disconnect the brake booster vacuum hose on the engine side. Refer to Removal and Installation .

.

.

.6. Disconnect the heater hose on the engine side.

7. Disconnect fuel feed hose at engine side. Refer to Removal and Installation .

.

.

.9. Disconnect the radiator hose (upper) on the engine side.

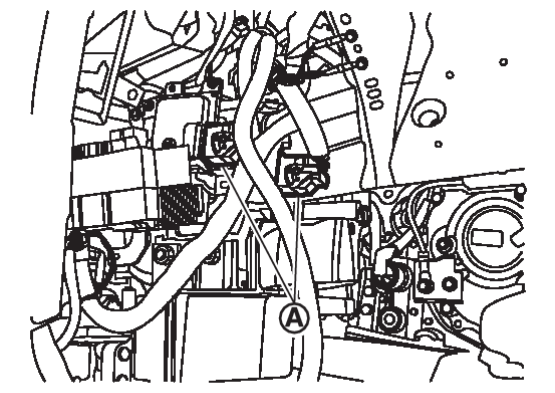

10. Disconnect CVT fluid cooler hose A and CVT fluid cooler hose B from the CVT oil warmer. Refer to Removal and Installation .

.

.

.Engine Room Underbody LH

Engine Room RH

1. Disconnect A/C low pressure piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to Exploded View .

.

.

.2. Remove ground cable at engine side.

3. Disconnect the reservoir tank hose on the reservoir tank side.

Vehicle inside

Disconnect steering column assembly at steering gear assembly side. Refer to Removal and Installation .

.

.

.Vehicle Underbody

1. Disconnect the radiator hose (lower) on the radiator side. Refer to Removal and Installation.Removal and Installation

2. Disconnect A/C high pressure piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to Exploded View .

.

.

.3. Remove propeller shaft (AWD models). Refer to Removal and Installation .

.

.

.4. Fasten the radiator at the upper radiator core support with a rope or similar.

6. Remove front suspension member. Refer to Removal and Installation .

.

.

.7. Remove front drive shafts (RH and LH). Refer to Removal and Installation (2WD models), Removal and Installation Removal and Installation

(2WD models), Removal and Installation Removal and Installation (AWD models).

(AWD models).

(2WD models), Removal and Installation Removal and Installation

(2WD models), Removal and Installation Removal and Installation (AWD models).

(AWD models).Removal

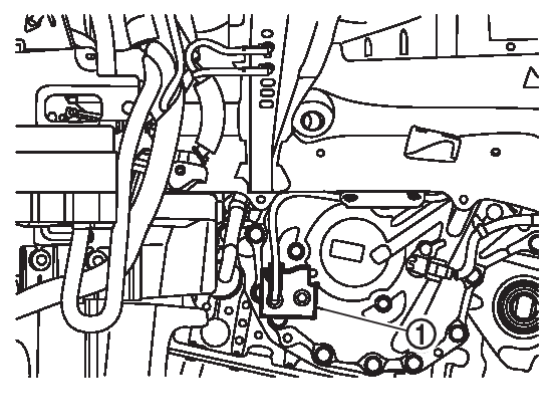

1. Use a manual lift table caddy (commercial service tool) or equivalently rigid tool such as a transmission jack. Securely support bottom of the engine and the transaxle assembly.

| caution | Put a piece of wood or an equivalent as the supporting surface, secure a completely stable condition. |

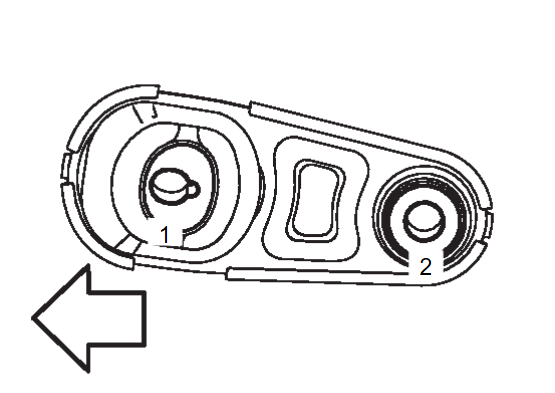

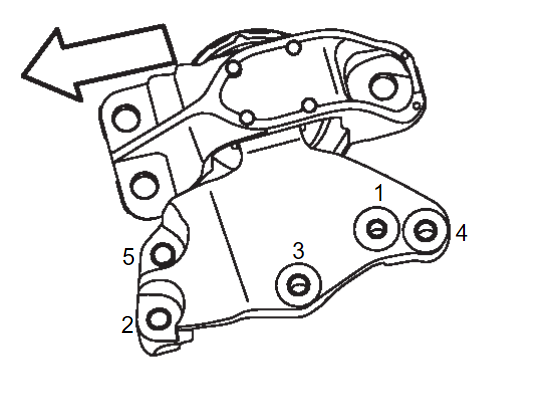

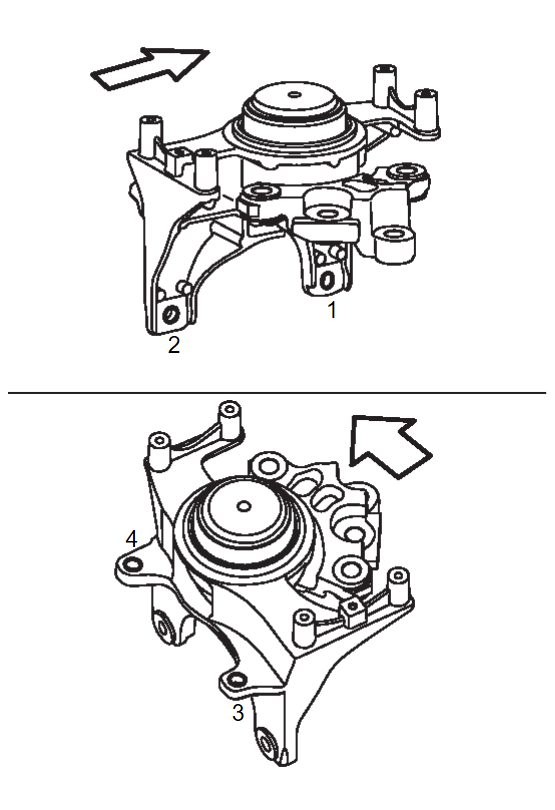

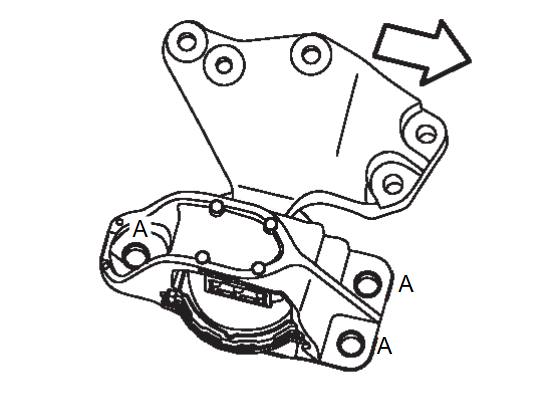

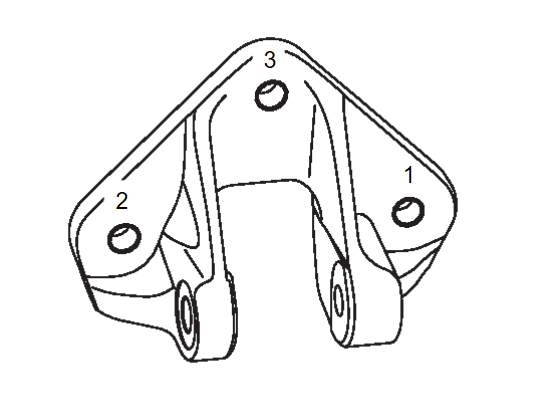

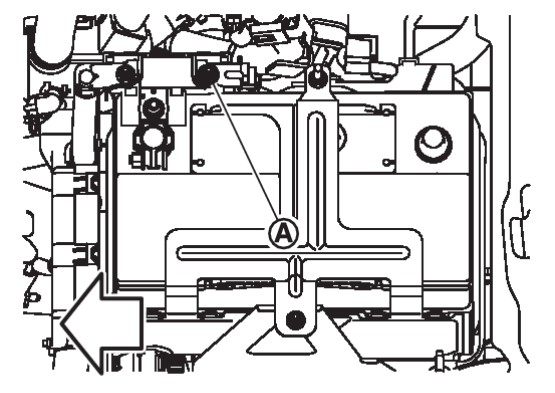

2. Remove engine mounting insulator bolts (RH).

- Loosen the mounting bolts in the reverse order as shown in the figure.

| : Vehicle front |

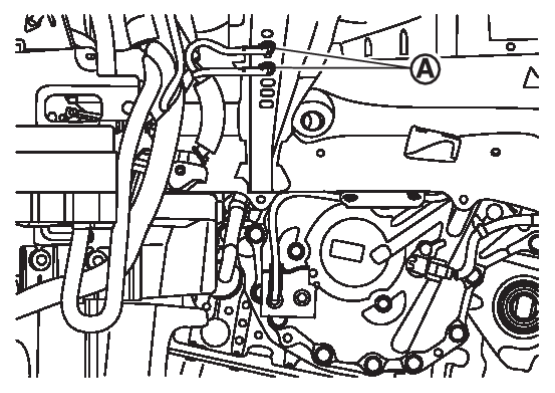

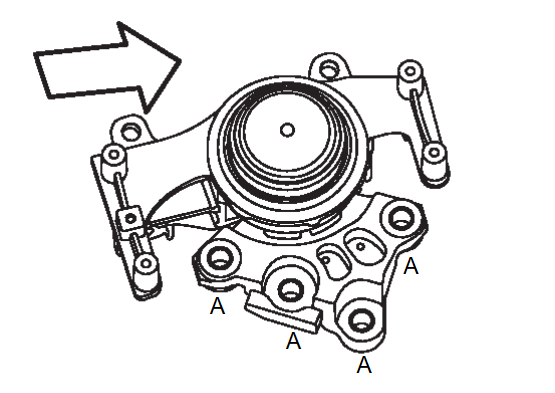

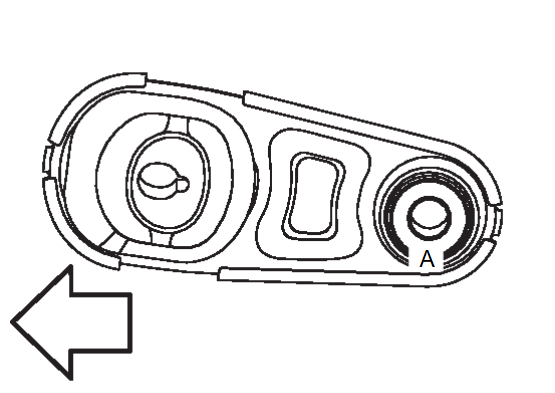

3. Remove engine mounting insulator bolts (LH).

- Loosen the mounting bolts (A) as shown in the figure.

| : Vehicle front |

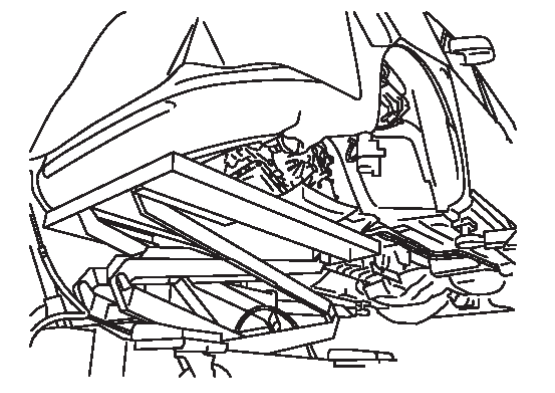

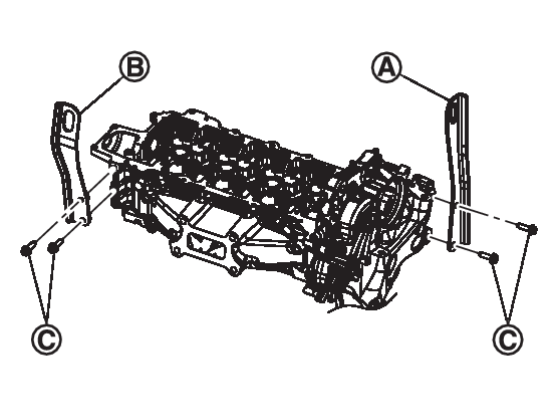

4. Remove engine and transaxle assembly from the vehicle by lowering (or raising the lift) a bottom supporting tool, such as manual lift table caddy (commercial service tool) or mission jack.

| caution |

|

Separation

1. Install engine slingers into front left of engine mount bracket (RH) and rear right of cylinder head.

Slinger bolts  | ||

Engine slinger  cylinder head side : cylinder head side : |  : 22.0 N·m (2.2 kg-m, 16 ft-lb) : 22.0 N·m (2.2 kg-m, 16 ft-lb) | |

Engine slinger  engine mount bracket side : engine mount bracket side : |  : 22.0 N·m (2.2 kg-m, 16 ft-lb) : 22.0 N·m (2.2 kg-m, 16 ft-lb) | |

2. Remove starter motor. Refer to Removal and Installation .

.

.

.3. Lift with a hoist and separate the engine from the transaxle assembly. Refer to Removal and Installation .

.

.

.INSTALLATION

Note the following, and install in the reverse order of removal.

| caution |

|

Preparation

1. Install the engine mounting insulator bolts (LH) as follows:

2. Install the engine mounting insulator bolts (RH) as follows:

Installation

1. Lift up the engine assembly to the vehicle.

2. Install the engine mounting insulator bolts (RH) as follows:

3. Install the engine mounting insulator bolts (LH) as follows:

4. Install the engine mounting insulator bolts (RH) as follows:

5. Remove bottom supporting tool, such as manual lift table caddy (commercial service tool) or mission jack.

| note | Check the engine mounting insulator is not twisted. |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

from vacuum delay valve assembly

from vacuum delay valve assembly  .

.