DTC No. P0D85-00: OBC DC output over voltage

| danger |

|

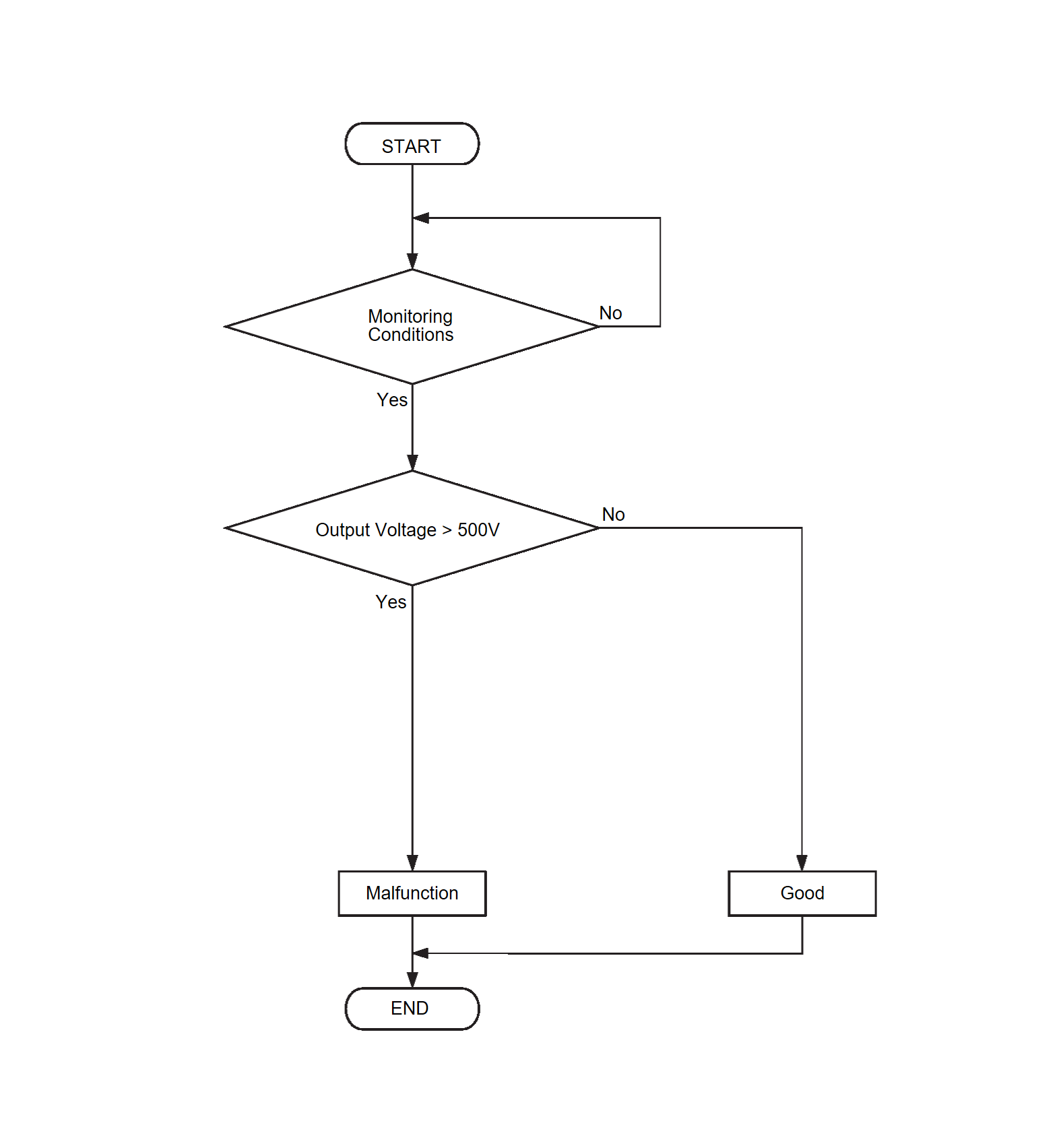

MONITOR EXECUTION

Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- On Board Charger (OBC) monitor

Sensor (The sensor below is determined to be normal)

- Output voltage sensor

Check Condition

- Charge permission from PHEV-ECU: ON

Judgment Criterion

- The output voltage is more than 500 volts.

OBD-II DRIVE CYCLE PATTERN

- Refer to OBD-II Drive Cycle OBD-II DRIVE CYCLE

.

.

TROUBLESHOOTING HINTS

- Malfunction of the high-voltage circuit

- Malfunction of the junction box

- Malfunction of the high-voltage fuse (30 A) for On Board Charger (OBC)/DC-DC converter

- Malfunction of the On Board Charger (OBC)/DC-DC converter

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991223: Wiring harness set

- MB992006: Extra fine probe

1.M.U.T.-IIISE other system DTC

Check whether the REMCU sets the following DTC. Troubleshoot the set DTCs (Refer to DTC No. P0C7A-00 Rear drive motor voltage-high

Troubleshoot the set DTCs (Refer to DTC No. P0C7A-00 Rear drive motor voltage-high ).

).

- DTC No.P30D1-16 Rear drive motor voltage-low

- DTC No.P0C7A-00 Rear drive motor voltage-high

Is the DTC set?

Troubleshoot the set DTCs (Refer to DTC No. P0C7A-00 Rear drive motor voltage-high

Troubleshoot the set DTCs (Refer to DTC No. P0C7A-00 Rear drive motor voltage-high ).

).2.Check of the high-voltage fuse (30 A) for On Board Charger (OBC)/DC-DC converter

| danger |

|

Check the continuity of the high-voltage fuse (30 A) for On Board Charger (OBC)/DC-DC converter in junction box (Refer to CHECK AND REPLACEMENT OF HIGH-VOLTAGE FUSE INSIDE THE JUNCTION BOX ).

).

).

).Is the check result normal?

Repace the high-voltage fuse (30 A) for On Board Charger (OBC)/DC-DC converter ( CHECK AND REPLACEMENT OF HIGH-VOLTAGE FUSE INSIDE THE JUNCTION BOX

Repace the high-voltage fuse (30 A) for On Board Charger (OBC)/DC-DC converter ( CHECK AND REPLACEMENT OF HIGH-VOLTAGE FUSE INSIDE THE JUNCTION BOX ).

).3.Visually check of the inside of the junction box

| danger |

|

Visually check that there is no burnout, damage, foreign material inside the junction box.

Is the check result normal?

Replace the junction box (Refer to JUNCTION BOX REMOVAL AND INSTALLATION

Replace the junction box (Refer to JUNCTION BOX REMOVAL AND INSTALLATION ).

).4.Check the installation of the P, N terminals on On Board Charger (OBC)/DC-DC converter.

| danger |

|

Check that the P, N terminals of the On Board Charger (OBC)/DC-DC converter is installed to the junction box with specified torque.

Is the check result normal?

Repair the installation.

Repair the installation.5.Check of continuity at the high-voltage circuit inside the junction box.

| danger |

|

(1) Check the continuity of the high-voltage circuit inside the junction box (Refer to CONTINUITY CHECK FOR HIGH VOLTAGE CIRCUIT IN JUNCTION BOX ).

).

).

).Is the check result normal?

Check the tightening torque of the fuse, or repalce the junction box.

Check the tightening torque of the fuse, or repalce the junction box.6.Test the OBD-II drive cycle.

(1) Carry out a test drive with the drive cycle pattern. Refer to OBD-II Drive Cycle OBD-II DRIVE CYCLE .

.

.

.(2) Check the DTC.

Is the DTC set?

Repalce the On Board Charger (OBC)/DC-DC converter (Refer to ON BOARD CHARGER (OBC) &DC-DC CONVERTER REMOVAL AND INSTALLATION

Repalce the On Board Charger (OBC)/DC-DC converter (Refer to ON BOARD CHARGER (OBC) &DC-DC CONVERTER REMOVAL AND INSTALLATION ).

). The trouble can be an intermittent malfunction (Refer to General Information - How to Use Troubleshooting/Inspection Service Points, How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

The trouble can be an intermittent malfunction (Refer to General Information - How to Use Troubleshooting/Inspection Service Points, How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)