DTC C121E: Abnormality in brake fluid pressure sensor output signal

OPERATION

The hydraulic sensor is incorporated in the hydraulic unit. When the brake pedal is depressed, the pressure sensor detects the brake pressure applied from the master cylinder, converts this pressure into the voltage signal, and outputs it.

DTC SET CONDITIONS

This DTCs will be stored under the cases below:

- When the pressure sensor offset is not within the standard value range

- When the estimated pressure sensor temperature is not normal

PROBABLE CAUSES

- Incorrect adjustment of brake pedal height

- Master cylinder malfunction

- Brake booster malfunction

- Incorrect installation position of stoplight switch

- Stoplight switch malfunction

- Brake drag

- ASC-ECU malfunction

DIAGNOSIS

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

Use scan tool MB991958 to diagnose the CAN bus lines.

Is the check result normal?

STEP 2. DTC recheck after resetting CAN bus lines

STEP 3. Brake pedal check

STEP 4. Check whether the other system DTC is stored.

Refer to GROUP 54A - Rear Combination Light/DTC chart  .

. Repair or replace the rear combination light or rear combination light circuit.

Repair or replace the rear combination light or rear combination light circuit.

.

.Is any DTC stored?

Repair or replace the rear combination light or rear combination light circuit.

Repair or replace the rear combination light or rear combination light circuit.STEP 5. Check for stoplight switch installation

STEP 6. Stoplight switch continuity check

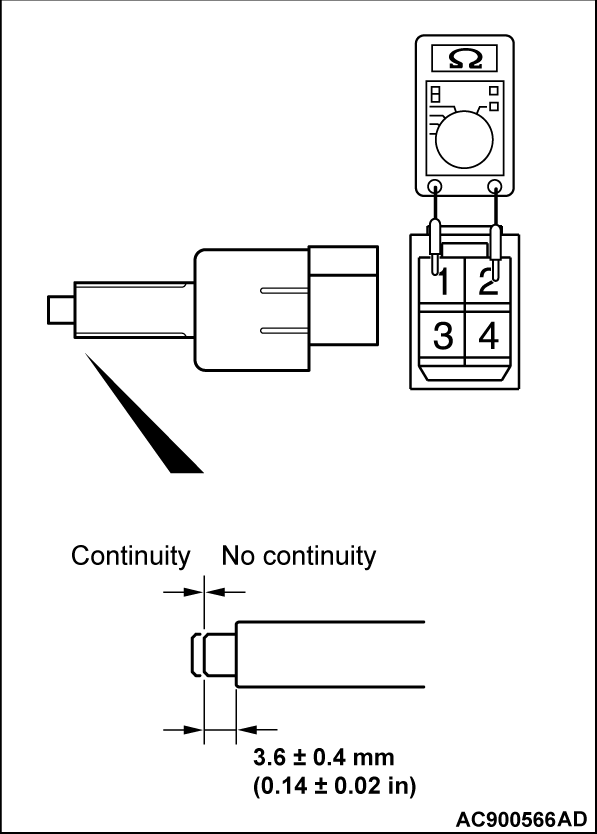

(2) Connect the circuit tester (Ω range) to the stop light switch connector terminals No.1 and No.2.

(3) When no continuity is detected with the plunger pressed from the edge of the outer case by the dimension shown in the figure and when continuity is detected with the plunger released, the stop light switch is in good condition.

Is the check result normal?

STEP 7. Brake drag check

Check the brake system for drag (Refer to GROUP 35A - On-vehicle Service/Brake Drag Force Check  ).

).

).

).Is the check result normal?

STEP 8. Brake booster check

STEP 9. Check whether the DTC is stored again.

Erase the DTC.

Is DTC C121E stored?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)