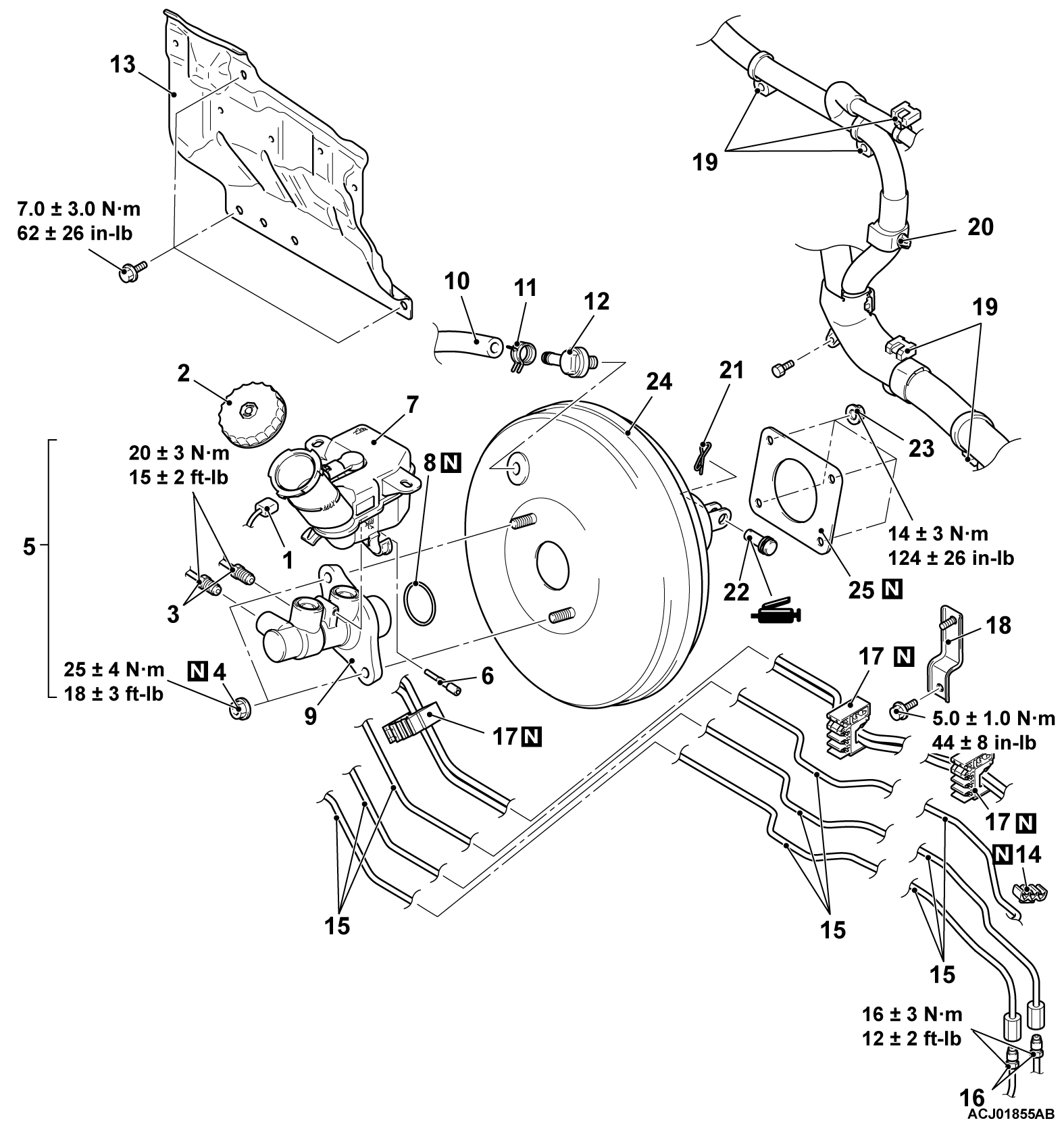

REMOVAL AND INSTALLATION

MASTER CYLINDER AND BRAKE BOOSTER

| caution |

|

Pre-removal operation | Post-installation operation |

REMOVAL SERVICE POINT

<<A>> MASTER CYLINDER ASSEMBLY REMOVAL

| caution |

|

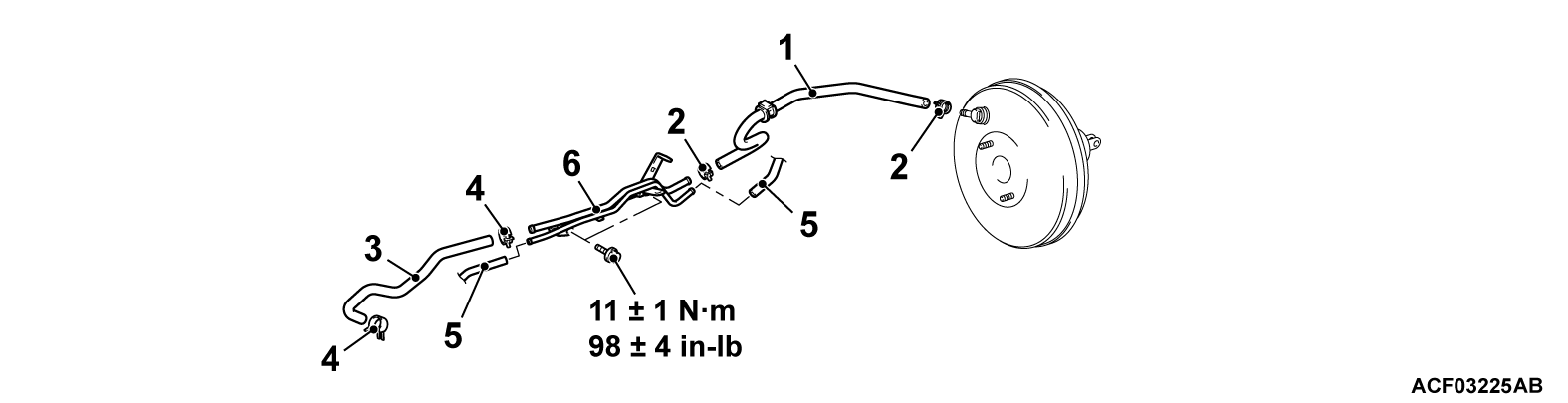

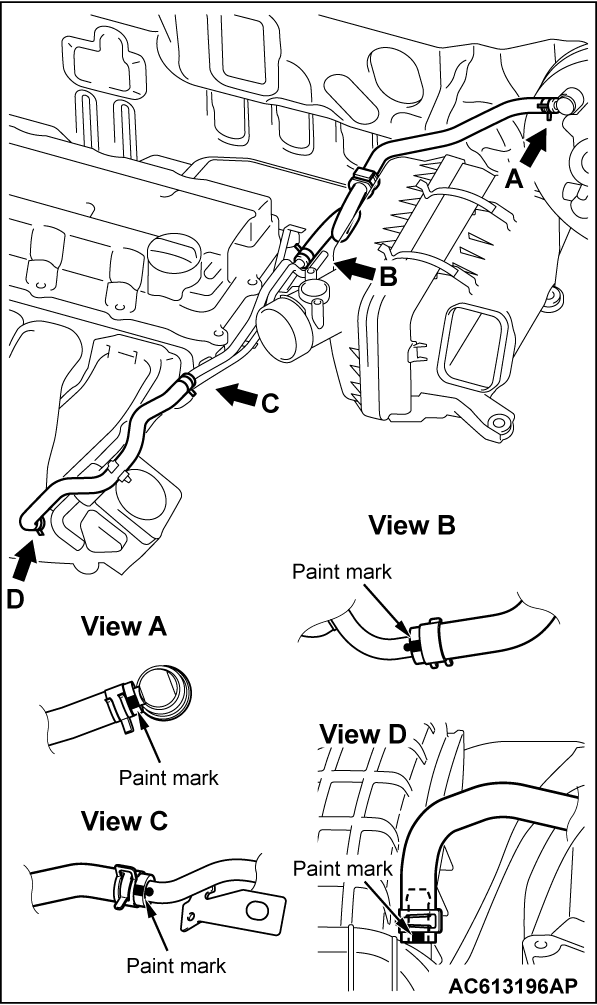

<VACUUM HOSE AND VACUUM PIPE>

INSTALLATION SERVICE POINTS

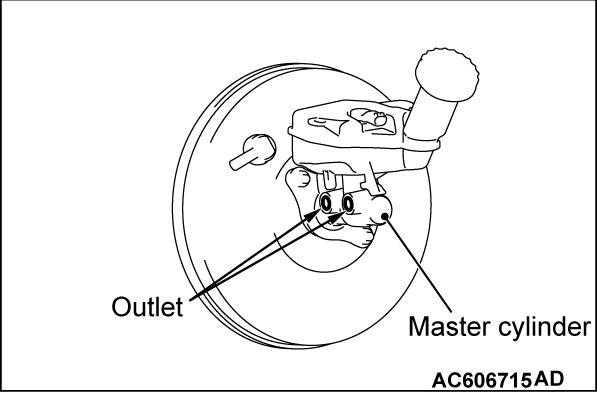

>>B<< BLEEDING OF MASTER CYLINDER ASSEMBLY

When removed the master cylinder assembly, bleed the master cylinder in the following procedure to make bleeding of the brake pipeline easier (When no brake fluid is in the master cylinder).

1. Fill the brake fluid reservoir with the brake fluid.

2. Depress and hold the brake pedal.

3. Another operator closes the master cylinder outlets with his fingers.

4. In this condition, release the brake pedal.

5. Repeat Steps 2 to 4 for 3 or 4 times to fill the master cylinder with the brake fluid.

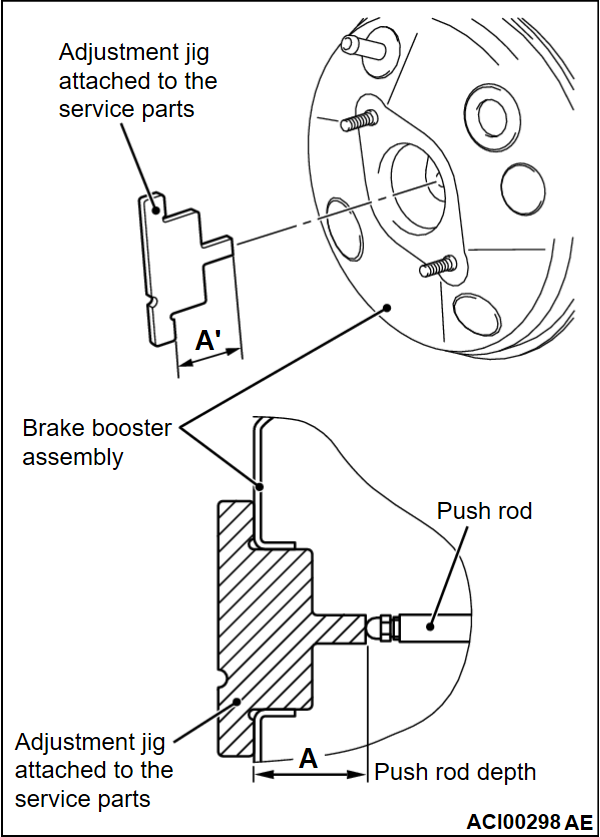

>>C<< PUSH ROD DEPTH ADJUSTMENT

| caution | When replacing the master cylinder assembly with the new one, the push rod depth must be adjusted using the adjustment jig attached to the service parts. When re-installing the removed master cylinder assembly, the adjustment is not necessary. |

1. Check that the push rod depth (A) and the length of the adjustment jig attached to the service parts (A’) are equal (A = A’).

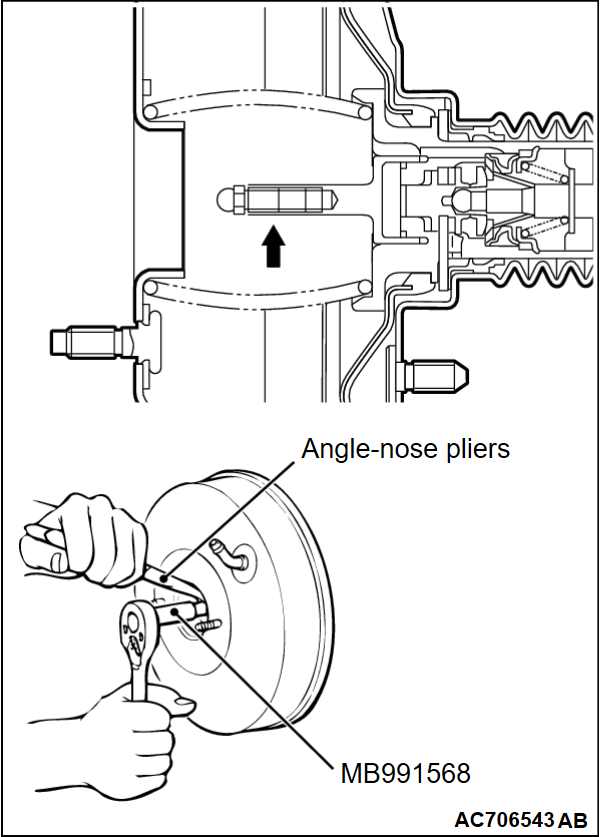

2. When the push rod depth differs from the jig length, use angle nose pliers to fix the push rod at the area indicated with an arrow. Then, use the push rod adjusting socket (special tool: MB991568) to rotate the push rod leading end, and adjust the push rod depth to match with the jig length.

| note | It is recommended to use the angle nose pliers that are commercially available. |

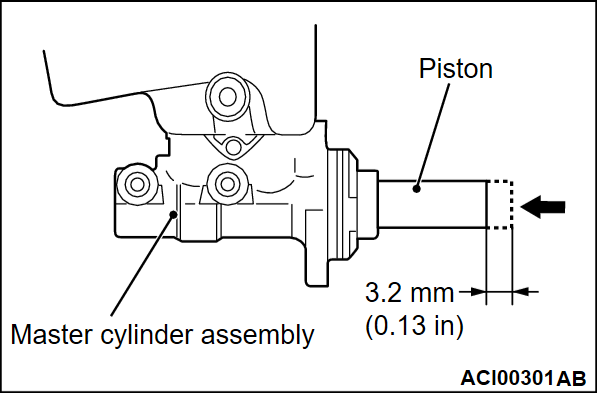

>>D<< MASTER CYLINDER ASSEMBLY INSTALLATION

| caution |

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)