DTC P0139-00: Heated oxygen sensor (rear) slow response

CIRCUIT OPERATION

- The sensor signal is inputted to the ECM connector terminal number 49 from the heated oxygen sensor (rear) connector terminal number 4.

- The heated oxygen sensor (rear) connector terminal number 3 is grounded with ECM connector terminal number 50.

- The ECM connector terminal number 50 applies an offset voltage of 0.5 volt to the heated oxygen sensor (rear) connector terminal number 3.

TECHNICAL DESCRIPTION

- The output signal of the linear air-fuel ratio sensor is compensated by the output signal of the heated oxygen sensor (rear).

- The ECM checks for the heated oxygen sensor (rear) output voltage.

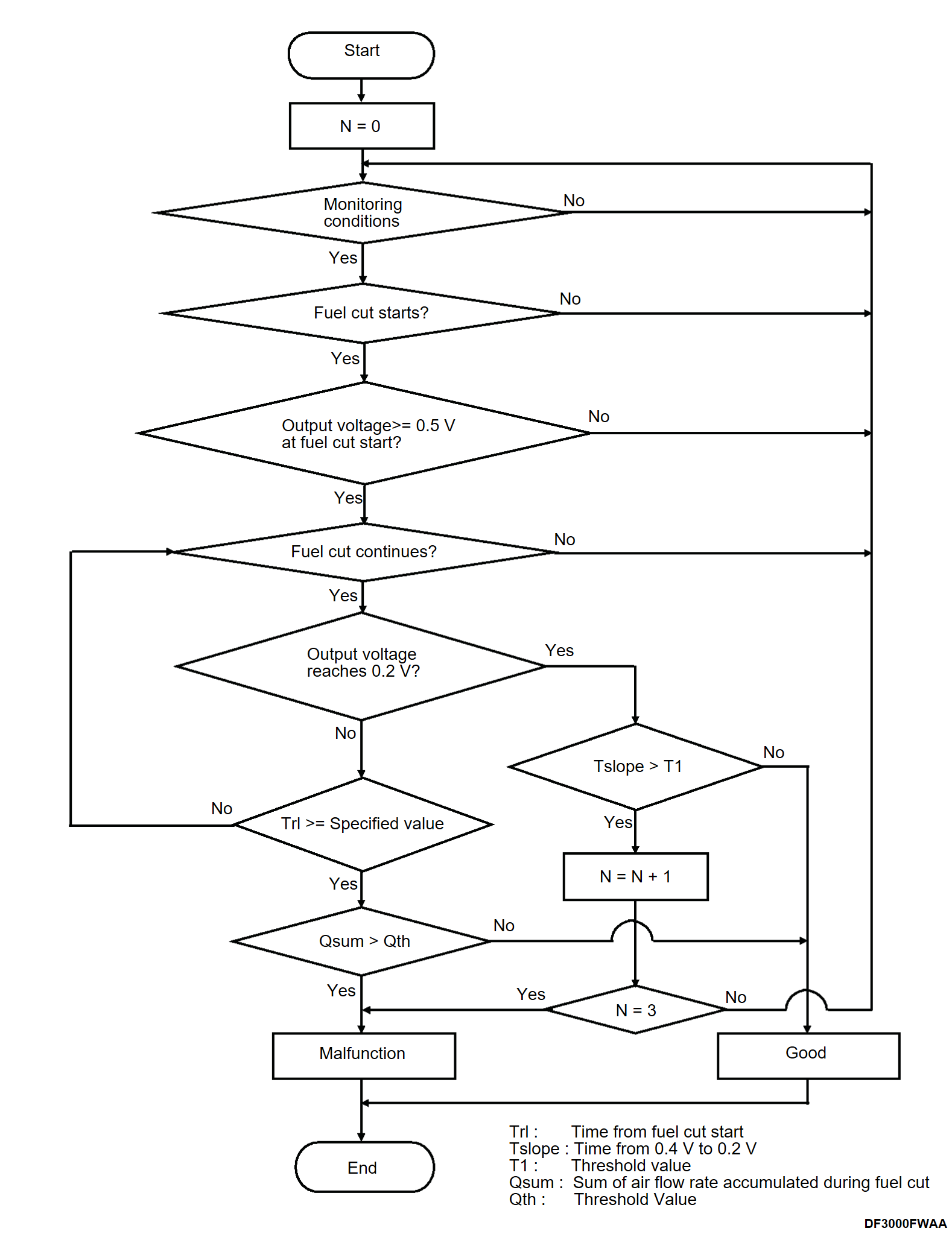

DESCRIPTIONS OF MONITOR METHODS

Heated oxygen sensor (rear) output voltage does not reach 0.2 volt after fuel cut operation.

MONITOR EXECUTION

Continuous.

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Linear air-fuel ratio sensor monitor

- Linear air-fuel ratio sensor heater monitor

- Heated oxygen sensor (rear) heater monitor

- Heated oxygen sensor offset voltage monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Fuel tank pressure sensor

DTC SET CONDITIONS

Check Conditions

- Fuel is being shut off.

- Engine coolant temperature is higher than 76°C (169°F).

- The linear air-fuel ratio sensor is active.

- It has been taking 180 seconds or more since the drive signal of the heated oxygen sensor (rear) heater was turned on.

- 5 seconds or more have passed since the estimated catalytic converter temperature is higher than 600°C (1,112°F).

- Heated oxygen sensor (rear) output voltage is 0.5 volt or higher when fuel cut is started.

- Barometric pressure is higher than 76 kPa (22.4 in.Hg).

- The cumulative mass airflow sensor output is lower than 200 g (7.05 oz.), while the open loop air-fuel ratio control.

- Heated oxygen sensor (rear) output voltage does not reach 0.2 volt for 3 seconds from fuel cut start.

- The cumulative mass airflow sensor output is higher than 2 g (0.071 oz.) before the heated oxygen sensor (rear) output voltage reaches 0.5 volt while fuel is being shut off.

- The ECM monitors for this condition for 3 cycles of 0.3 second each during drive cycles.

Judgment Criterion

- The cumulative mass airflow sensor output is higher than 11 g (0.39 oz.), while fuel is being shut off.or

- The heated oxygen sensor (rear) output voltage does not reach 0.2 volt for 0.3 second from 0.4 volt while fuel is being shut off.

- The ECM monitors for this condition once during the drive cycle.

| note | Monitoring stops when the estimated catalytic converter temperature is 500°C (932°F) or lower. |

FAIL-SAFE AND BACKUP FUNCTION

None.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 5 OBD- II DRIVE CYCLE .

.

.

.TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Heated oxygen sensor (rear) deteriorated.

- Connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

1.STEP 1. Using scan tool (M.U.T.-III SE), check the data list.

(1) Connect scan tool (M.U.T.-III SE) to the data link connector (Refer to HOW TO CONNECT THE SCAN TOOL (M.U.T.-III SE) ).

).

).

).(2) Set the vehicle to the continuous idling mode (Refer to GENERAL INFORMATION, General Information – Precautions CONTINUOUS IDLING MODE ).

).

).

).(3) Set scan tool (M.U.T.-III SE) to the data reading mode for item number A1501: Oxygen sensor(bank1 sensor2).

(4) Warm up the engine.

- After increasing the output voltage 0.5 volt or more by the engine revving, finish it. Then confirm that the output voltage reduces to 0.2 volt or less within 6 seconds.

(5) Turn off the power supply mode of the electric motor switch.

Q: Is the sensor operating properly?

Replace the heated oxygen sensor (rear) (Refer to ENGINE, Engine, Motor and Emission Control – Emission Control – Exhaust Gas Purification System CATALYTIC CONVERTER REMOVAL AND INSTALLATION

Replace the heated oxygen sensor (rear) (Refer to ENGINE, Engine, Motor and Emission Control – Emission Control – Exhaust Gas Purification System CATALYTIC CONVERTER REMOVAL AND INSTALLATION ). Then

). Then

2.STEP 2. Test the OBD-II drive cycle.

After erasing the DTC, carry out test drive with the drive cycle pattern, and recheck the DTC. Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).

(1) Use scan tool (M.U.T.-III SE) to erase the DTC.

(2) Carry out test drive with the drive cycle pattern (Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 5 OBD- II DRIVE CYCLE ).

).

).

).(3) Use scan tool (M.U.T.-III SE) to recheck the DTC.

Q: Is DTC P0139-00 set?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).3.STEP 3. Test the OBD-II drive cycle.

After erasing the DTC, carry out test drive with the drive cycle pattern, and recheck the DTC. Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). The inspection is complete.

The inspection is complete.

(1) Use scan tool (M.U.T.-III SE) to erase the DTC.

(2) Carry out test drive with the drive cycle pattern (Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 5 OBD- II DRIVE CYCLE ).

).

).

).(3) Use scan tool (M.U.T.-III SE) to recheck the DTC.

Q: Is DTC P0139-00 set?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). The inspection is complete.

The inspection is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)