DTC P2420-00: EVAP System Switching Valve Control Circuit High

CIRCUIT OPERATION

- The 12V battery voltage is applied to the fuel tank solenoid valve connector terminal number 1 from the ECM connector terminal number 92.

- The fuel tank solenoid valve connector terminal number 2 is grounded with the vehicle body.

TECHNICAL DESCRIPTION

Seal the fuel tank and keep the fuel tank internal pressure. In response to a signal from the ECM, open the fuel tank solenoid valve and release the sealed state of the fuel tank.

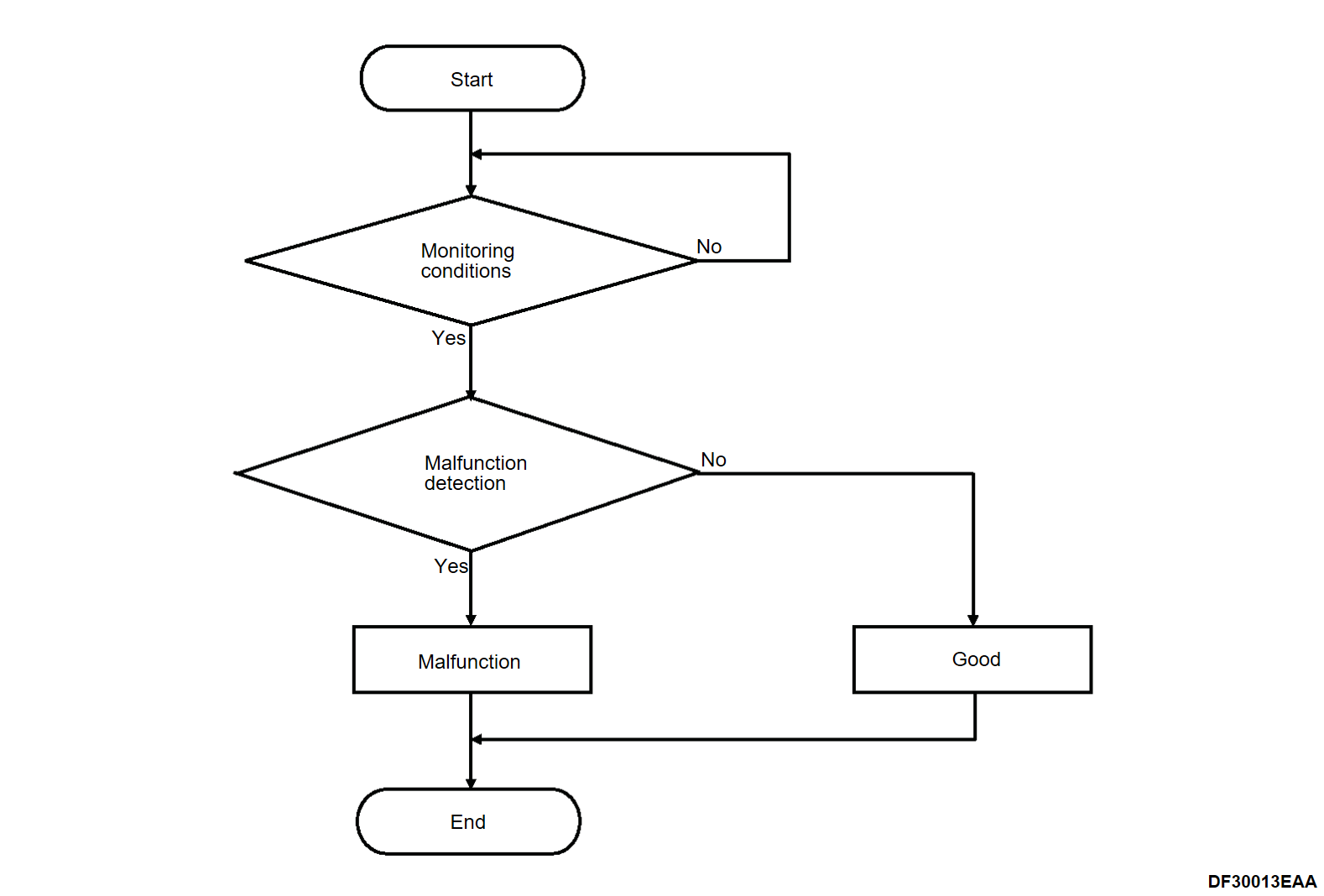

MONITOR EXECUTION

Continuous.

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- Power supply mode of electric motor switch is ON.

- 12V battery positive voltage is between 10.0 and 16.5 volts.

Judgment Criterion

- Monitor circuit voltage is higher than 1.5 volts for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Fuel filler lid cannot be opened even when pressing the fuel filler lid opener switch.

- Indicates "REFUELING SYSTEM SERVICE REQUIRED" on the information screen in the multi-information display.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 1 OBD- II DRIVE CYCLE .

.

.

.TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Fuel tank solenoid valve failed.

- Open or shorted fuel tank solenoid valve circuit, harness damage or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

1.STEP 1. Using scan tool (M.U.T.-IIISE), perform the actuator test.

Use scan tool (M.U.T.-III SE) to perform the actuator test (Refer to ACTUATOR TEST REFERENCE TABLE ).

).

).

).- Item number 100: EVAP system sealing valve

OK: Select ON to drive the solenoid valve.

Q: Is the check result normal?

2.STEP 2. Check the fuel tank solenoid valve.

Check coil resistance of fuel tank solenoid valve (Refer to ENGINE, Engine, Motor and Emission Control – Emission Control – Evaporative Emission System FUEL TANK SOLENOID VALVE CHECK ).

). Replace fuel tank solenoid valve (Refer to ENGINE, Fuel Supply – Fuel Tank FUEL TANK DISASSEMBLY AND ASSEMBLY

Replace fuel tank solenoid valve (Refer to ENGINE, Fuel Supply – Fuel Tank FUEL TANK DISASSEMBLY AND ASSEMBLY )

)

).

).OK: 25 to 30 ohms [at 20°C (68°F)]

Q: Is the check result normal?

Replace fuel tank solenoid valve (Refer to ENGINE, Fuel Supply – Fuel Tank FUEL TANK DISASSEMBLY AND ASSEMBLY

Replace fuel tank solenoid valve (Refer to ENGINE, Fuel Supply – Fuel Tank FUEL TANK DISASSEMBLY AND ASSEMBLY )

)3.STEP 3. Check harness between fuel tank solenoid valve connector terminal number 1 and ECM connector terminal number 92.

Check power supply line for short to power supply. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.4.STEP 4. Check harness between fuel tank solenoid valve connector terminal number 2 and ground.

Check ground line for open circuit or damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.5.STEP 5. Using scan tool (M.U.T.-IIISE), perform the actuator test.

Use scan tool (M.U.T.-III SE) to perform the actuator test (Refer to ACTUATOR TEST REFERENCE TABLE ).

). Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

).

).

).- Item number 100: EVAP system sealing valve

OK: Select ON to drive the solenoid valve.

Q: Is the check result normal?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

).6.STEP 6. Test the OBD-II drive cycle.

After erasing the DTC, carry out test drive with the drive cycle pattern, and recheck the DTC. Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).

(1) Use scan tool (M.U.T.-III SE) to erase the DTC.

(2) Carry out test drive with the drive cycle pattern (Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 1 OBD- II DRIVE CYCLE ).

).

).

).(3) Use scan tool (M.U.T.-III SE) to recheck the DTC.

Q: Is DTC P2420-00 set?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)