DTC P0301-00: Misfire monitor(Cylinder 1 misfire detected),

DTC P0302-00: Misfire monitor(Cylinder 2 misfire detected),

DTC P0303-00: Misfire monitor(Cylinder 3 misfire detected),

DTC P0304-00: Misfire monitor(Cylinder 4 misfire detected)

DTC P0302-00: Misfire monitor(Cylinder 2 misfire detected),

DTC P0303-00: Misfire monitor(Cylinder 3 misfire detected),

DTC P0304-00: Misfire monitor(Cylinder 4 misfire detected)

CIRCUIT OPERATION

- MFI relay is built into the IPDM E/R.

- Power is supplied from the MFI relay to each fuel injector connector (terminal number 2).

- The ECM connector terminal number 3, 4, 5, 6 turn on the power transistor in the unit, and electrical current flows to each fuel injector connector (terminal number 1).

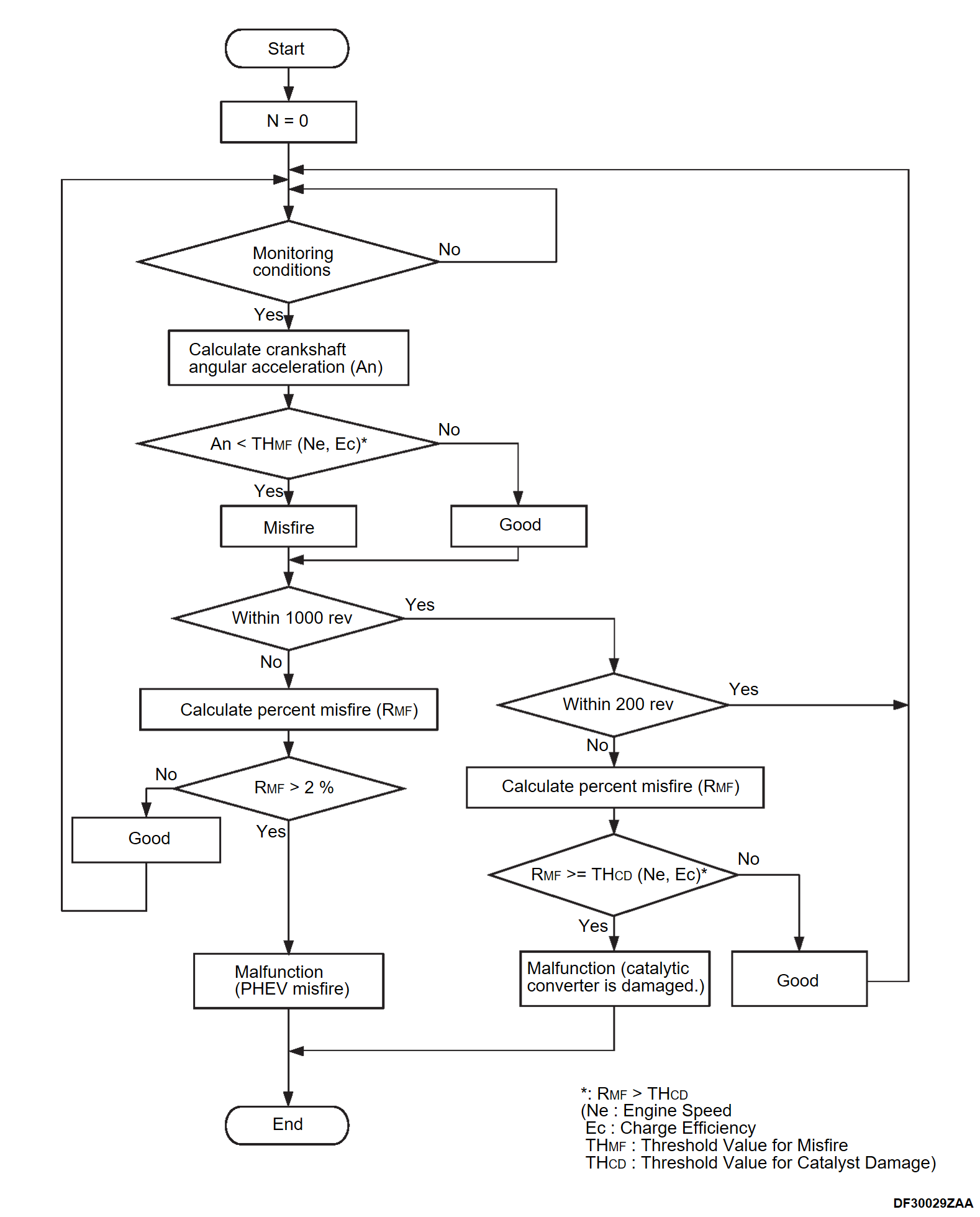

TECHNICAL DESCRIPTION

- If a misfire occurs while the engine is running, the engine speed changes for an instant.

- The ECM checks for such changes in engine speed.

DESCRIPTIONS OF MONITOR METHODS

Monitor angular acceleration of crankshaft and detect malfunction when negative variation of the angular acceleration is large.

MONITOR EXECUTION

Continuous.

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Camshaft position sensor

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Throttle position sensor

- Fuel tank pressure sensor

DTC SET CONDITIONS

Check Conditions

- Engine speed is between 188 and 5,250 r/min.

- The engine load is with in the positive torque load.

- Barometric pressure is higher than 76 kPa (22.4 in.Hg).

- Engine coolant temperature is higher than –10°C (14°F).or

- Engine coolant temperature is higher than 20°C (68°F) <When engine coolant temperature is –10°C (14°F) or lower at engine start>

- Adaptive learning is complete for the vane which generates a crankshaft position signal.

- While the engine is running, excluding sudden acceleration/deceleration and fuel shut-off operation.

Judgment Criterion (change in the angular acceleration of the crankshaft is used for misfire detection)

- Misfire counts per 1,000 revolutions exceeds in 2.0 percent.

Check Conditions

- Engine speed is between 188 and 5,250 r/min.

- The engine load is with in the positive torque load.

- Barometric pressure is higher than 76 kPa (22.4 in.Hg).

- Engine coolant temperature is higher than –10°C (14°F).or

- Engine coolant temperature is higher than 20°C (68°F) <When engine coolant temperature is –10°C (14°F) or lower at engine start>

- Adaptive learning is complete for the vane which generates a crankshaft position signal.

- While the engine is running, excluding sudden acceleration/deceleration and fuel shut-off operation.

Judgment Criterion (change in the angular acceleration of the crankshaft is used for misfire detection)

- Misfire has occurred more frequently than allowed during the last 200 revolutions [when the catalyst temperature is higher than 1,000°C (1,832°F)].

FAIL-SAFE AND BACKUP FUNCTION

The supply of fuel to the misfiring cylinder can possibly be cut.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 2 OBD- II DRIVE CYCLE .

.

.

.TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Ignition system related part(s) failed.

- Fuel injector failed.

- Harness damage in each fuel injector circuit.

- Low compression pressure.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

1.STEP 1. Visual check of ignition spark.

(1) Remove the spark plug and attach the removed spark plug to the ignition coil (Refer to ENGINE, Engine Electrical – Ignition Coil IGNITION COIL REMOVAL AND INSTALLATION ).

).

).

).(2) Disconnect the fuel injector connectors for all cylinders.

(3) Connect the ignition coil connector.

(4) Ground the ground electrode of the spark plug, and set the vehicle to the continuous idling mode (Refer to GENERAL INFORMATION, General Information – Precautions CONTINUOUS IDLING MODE ).

).

).

).(5) Check that the electrode of the spark plug sparks.

Q: Are the check result normal?

Perform troubleshooting for the ignition system (Refer to symptom procedure for inspection procedure 13: Ignition Circuit System Ignition circuit system

Perform troubleshooting for the ignition system (Refer to symptom procedure for inspection procedure 13: Ignition Circuit System Ignition circuit system ).

).2.STEP 2. Check fuel injector itself.

Check number 1 cylinder fuel injector, number 2 cylinder fuel injector, number 3 cylinder fuel injector and number 4 cylinder fuel injector itself (Refer to FUEL INJECTOR CHECK ).

). Replace the fuel injector (Refer to FUEL INJECTOR REMOVAL AND INSTALLATION

Replace the fuel injector (Refer to FUEL INJECTOR REMOVAL AND INSTALLATION ).

).

).

).Q: Are the check result normal?

Replace the fuel injector (Refer to FUEL INJECTOR REMOVAL AND INSTALLATION

Replace the fuel injector (Refer to FUEL INJECTOR REMOVAL AND INSTALLATION ).

).3.STEP 3. Check harness between IPDM E/R connector terminal number 66 and number 1 cylinder fuel injector connector terminal number 2.

Check power supply line for damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.4.STEP 4. Check harness between IPDM E/R connector terminal number 66 and number 2 cylinder fuel injector connector terminal number 2.

Check power supply line for damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.5.STEP 5. Check harness between IPDM E/R connector terminal number 66 and number 3 cylinder fuel injector connector terminal number 2.

Check power supply line for damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.6.STEP 6. Check harness between IPDM E/R connector terminal number 66 and number 4 cylinder fuel injector connector terminal number 2.

Check power supply line for damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.7.STEP 7. Check harness between number 1 cylinder fuel injector connector terminal number 1 and ECM connector terminal number 3.

Check output line for open/short circuit and damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.8.STEP 8. Check harness between number 2 cylinder fuel injector connector terminal number 1 and ECM connector terminal number 4.

Check output line for open/short circuit and damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.9.STEP 9. Check harness between number 3 cylinder fuel injector connector terminal number 1 and ECM connector terminal number 5.

Check output line for open/short circuit and damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.10.STEP 10. Check harness between number 4 cylinder fuel injector connector terminal number 1 and ECM connector terminal number 6.

Check output line for open/short circuit and damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.11.STEP 11. Check compression pressure.

Check the compression pressure (Refer to ENGINE, Engine Mechanical – On-vehicle Service COMPRESSION PRESSURE CHECK ).

). Repair it.

Repair it.

).

).Q: Is the check result normal?

Repair it.

Repair it.12.STEP 12. Test the OBD-II drive cycle.

After erasing the DTC, carry out test drive with the drive cycle pattern, and recheck the DTC. Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).

(1) Use scan tool (M.U.T.-III SE) to erase the DTC.

(2) Carry out test drive with the drive cycle pattern (Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 2 OBD- II DRIVE CYCLE ).

).

).

).(3) Use scan tool (M.U.T.-III SE) to recheck the DTC.

Q: Is DTC P0301-00, P0302-00, P0303-00, or P0304-00 set?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)