REMOVAL AND INSTALLATION

| caution | Whenever you removal the windshield, calibrate its sensor (Refer to GROUP 54A - FCM/LDW/AHB-ECU - On-vehicle Service, FCM/LDW/AHB-ECU Sensor Calibration  ) <Vehicles with FCM>. ) <Vehicles with FCM>. |

REMOVAL SERVICE POINTS

<<A>> WINDSHIELD GLASS REMOVAL

1. In order to protect the body (paint surface), apply a cloth tape to the body area along the windshield glass opening.

2. When separating adhesive using a piano wire

(1) Use a knife to cut away the molding.

(2) Use a sharp-point drill to make a hole in the windshield adhesive.

(3) Pass the piano wire from the inside of the vehicle through the hole.

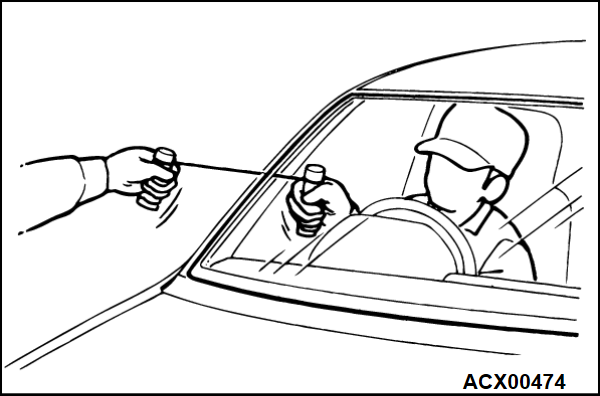

(4)

Pull the piano wire alternately from the inside and outside along the windshield glass to cut away the adhesive.

| caution |

|

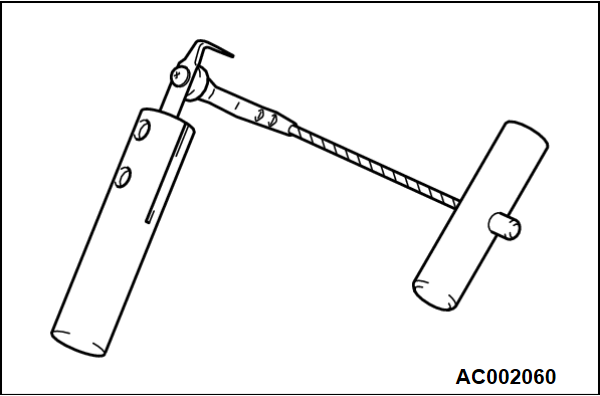

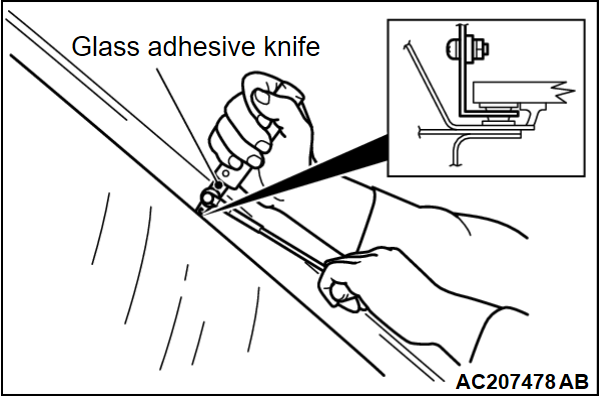

3. When cutting away adhesive using a windshield knife

(1) Using glass adhesive knife

(2)

Holding the tip of the glass adhesive knife and the windshield glass edge at right angles, align the blade of the glass adhesive knife with the windshield glass surface and edge, and pull the blade parallel to the edge to cut away the adhesive.

| caution | If you lever the glass adhesive knife, the windshield glass may be damaged. |

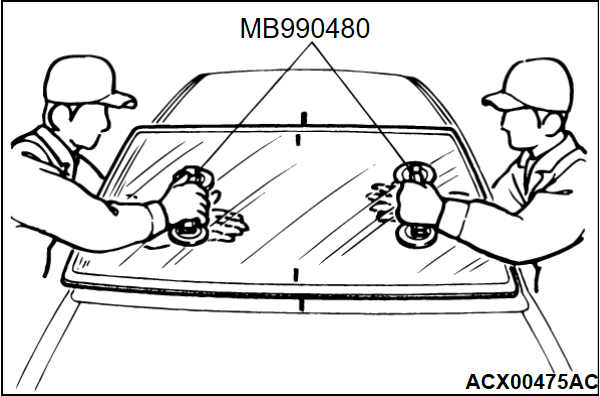

4. Make mating marks on the windshield glass and body, and use the special tool window glass holder (MB990480) to remove the windshield glass.

5.

| caution |

|

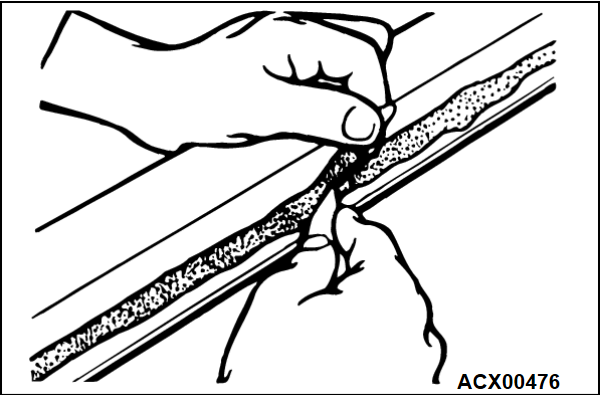

Use a knife to cut away the remaining adhesive so that the thickness is within 2.0 mm (0.1 inch) around the entire circumference of the body flange.

6. Finish the flange surfaces so that they are smooth.

7. If the windshield glass is reused, scrape away all traces of old adhesive, the glass stopper, and the windshield spacer.

INSTALLATION SERVICE POINTS

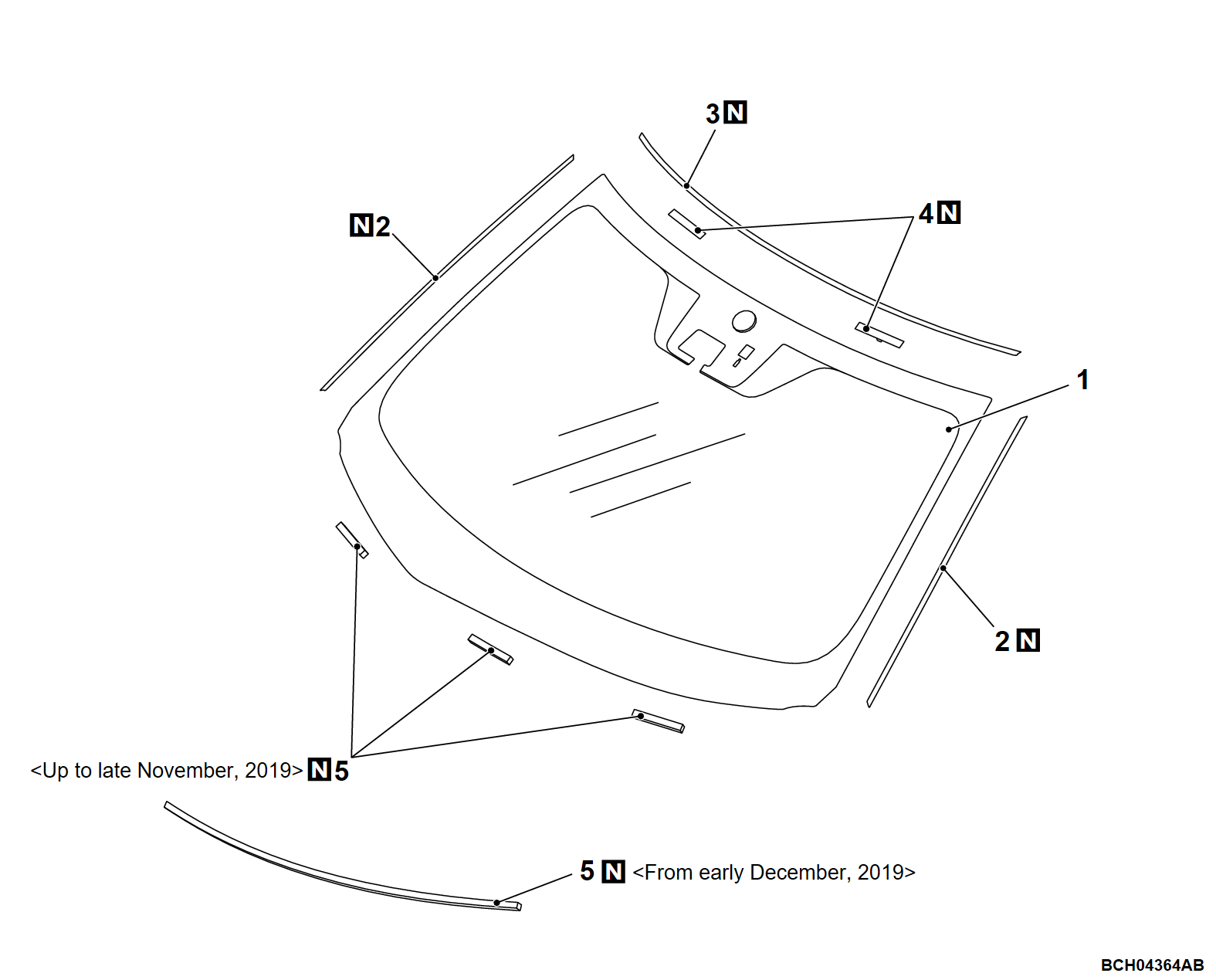

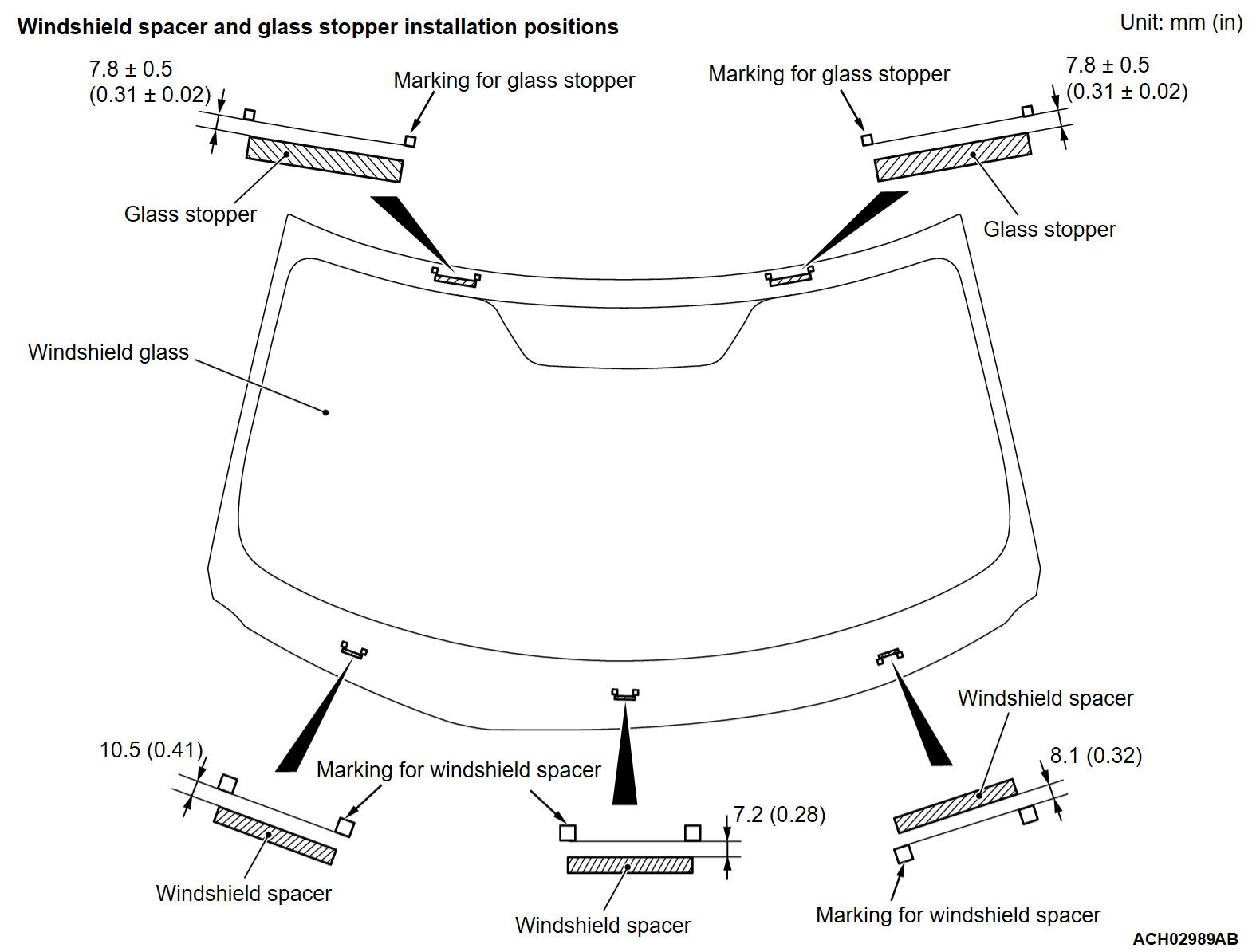

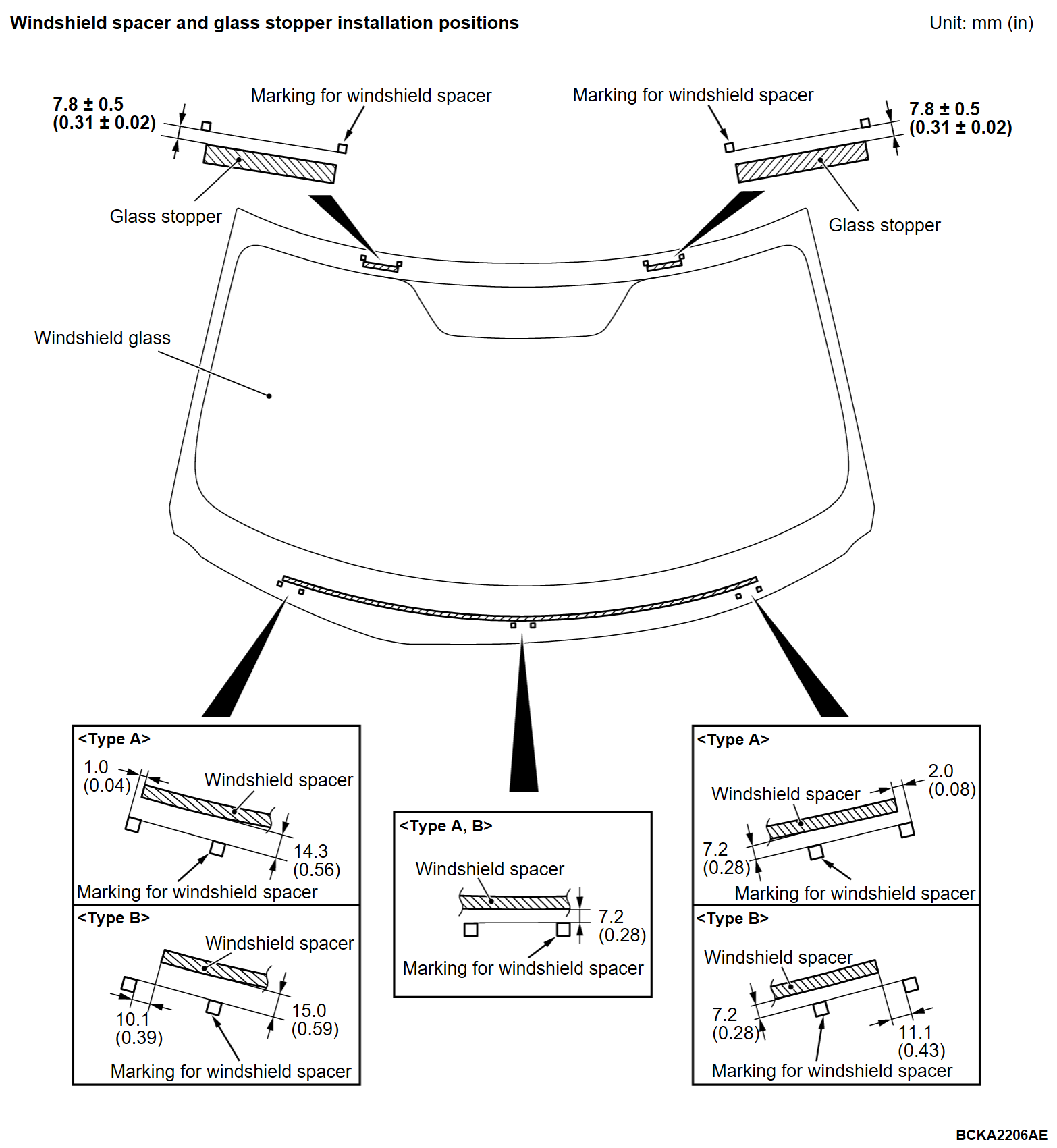

>>A<< WINDSHIELD SPACER <Up to late November, 2019>/GLASS STOPPER INSTALLATION

<Up to late November, 2019>

1.

| caution | Before the next operation, leave the decreased parts for 3 minutes or more to dry. Do not touch the coated surface. |

Use parts cleaner (MZ100387 or equivalent) to degrease the inside circumference of the windshield glass and the body flanges.

2.

Position the windshield spacer, ensuring that there are no bends or looseness inside the windshield glass.

3. Secure the glass stoppers to the specified positions on the windshield glass.

<From early December, 2019>

1.

| caution | Before the next operation, leave the decreased parts for 3 minutes or more to dry. Do not touch the coated surface. |

Use parts cleaner (MZ100387 or equivalent) to degrease the inside circumference of the windshield glass and the body flanges.

2. Measure the length of the windshield spacer.

- 1,020 mm (40.2 in) → Type A

- 1,000 mm (39.4 in) → Type B

3.

Position the windshield spacer, ensuring that there are no bends or looseness inside the windshield glass.

4. Secure the glass stoppers to the specified positions on the windshield glass.

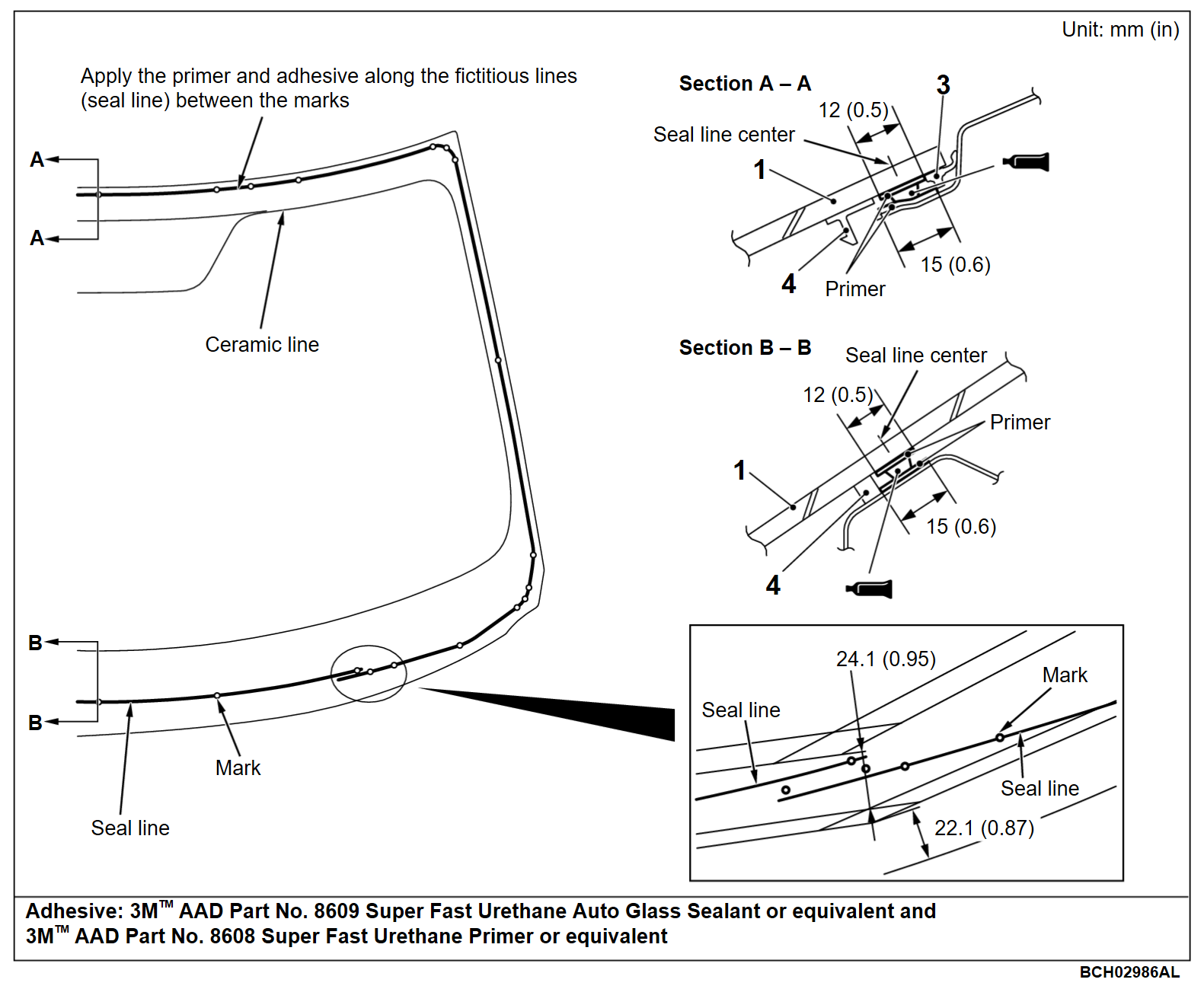

>>B<< WINDSHIELD GLASS INSTALLATION

1. Install the windshield molding to the windshield glass.

2. To replace the windshield glass, temporarily set the windshield glass against the body, and place mating marks on the body and windshield glass.

3.

| caution |

|

Soak a sponge in the primer, and apply evenly to the windshield glass and the body in the specified places.

4. After applying the primer, let it dry for 3 minutes or more.

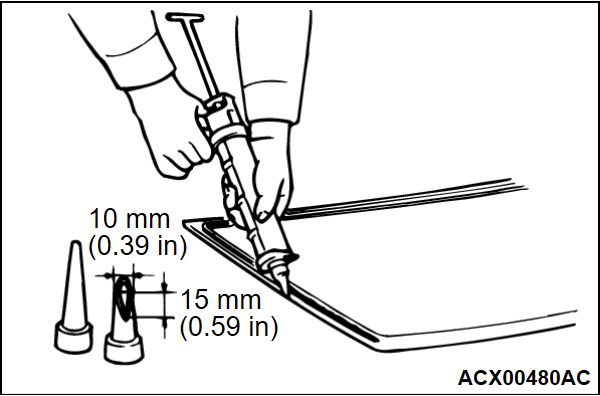

5. Fill a sealant gun with adhesive. Then apply the adhesive evenly around the windshield glass within 30 minutes after the primer application.

| note | Cut the tip of the sealant gun nozzle into a V-shape to simplify adhesive application. |

6. After applying the adhesive, align the mating marks on the windshield glass and the body, and then press the windshield glass gently to seat it.

7. Use spatula or the like to remove any excessive adhesive. Then clean the surface with parts cleaner (MZ100387 or equivalent). Leave the vehicle stationary until the adhesive sets (Refer to Window Glass Installation  ).

).

).

).8.

| caution |

|

Wait 30 minutes or more, and then test for water leakage.

INSPECTION EMBLEM REMOVAL AND INSTALLATION

1. Use your hands or a plastic spatula to remove the inspection emblem.

2. Remove the remaining adhesive using diluted mild detergent for home use or inorganic solution (alcohol).

3. Attach the new inspection emblem to the specified position.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)