DTC P0123-00: Throttle Position Sensor (main) circuit high input

CIRCUIT OPERATION

- Throttle position sensor is built into the throttle body assembly.

- A power voltage of 5 volts is applied to the throttle body assembly connector terminal number 5 from the ECM connector terminal number 32.

- The power voltage is earthed to the ECM connector terminal number 33 from the throttle body assembly connector terminal number 3.

- The sensor signal is inputted to the ECM connector terminal number 43 from the throttle body assembly connector terminal number 4.

TECHNICAL DESCRIPTION

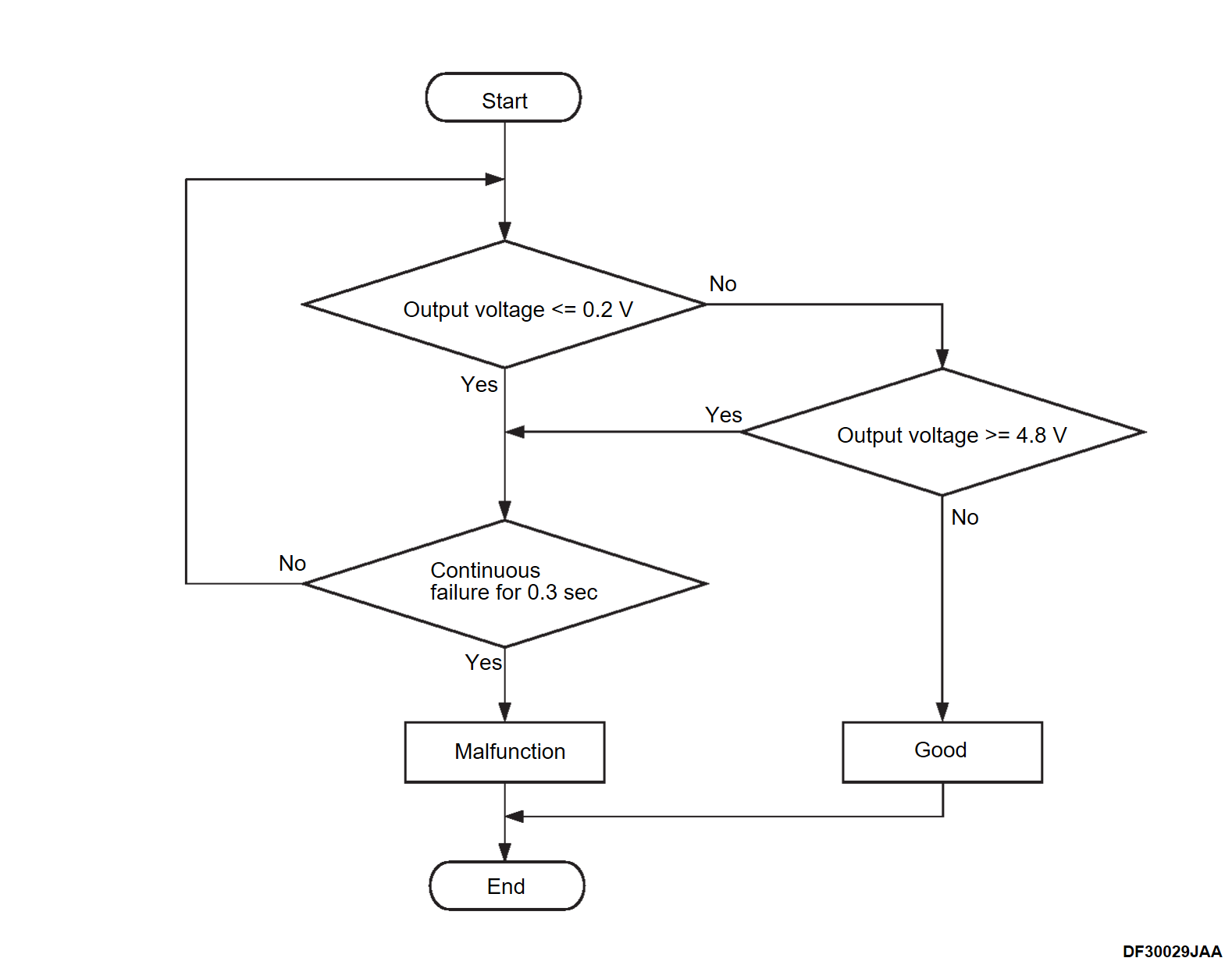

- The throttle position sensor (main) outputs voltage which corresponds to the throttle valve opening degree.

- The ECM checks whether the voltage is within a specified range.

DESCRIPTIONS OF MONITOR METHODS

Throttle position sensor (main) output voltage is out of specified range.

MONITOR EXECUTION

Continuous.

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Condition

- Power supply mode of electric motor switch is ON.

Judgment Criterion

- Throttle position sensor (main) output voltage should be 4.8 volts or higher for 0.3 second.

FAIL-SAFE AND BACKUP FUNCTION

- Throttle opening degree is restricted.

- Throttle opening degree position is in default position if throttle position sensor (sub) fails.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 1 OBD- II DRIVE CYCLE .

.

.

.TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Throttle position sensor (built into the throttle body assembly) failed.

- Open or shorted throttle position sensor (main) circuit, harness damage or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

1.STEP 1. Using scan tool (M.U.T.-III SE), check the data list.

Use scan tool (M.U.T.-III SE) to check the data list (Refer to DATA LIST REFERENCE TABLE ).

).

).

).- Item number 90: TPS (Main)

Q: Is the check result normal?

2.STEP 2. Perform voltage measurement at throttle body assembly connector terminal number 5.

- Disconnect connector, and measure at harness side.

- Power supply mode of electric motor switch: ON

- Voltage between throttle body assembly connector terminal number 5 and ground.

OK: 4.9 to 5.1 volts

Q: Is the check result normal?

3.STEP 3. Perform resistance measurement at throttle body assembly connector terminal number 3.

- Disconnect connector, and measure at harness side.

- Resistance between throttle body assembly connector terminal number 3 and ground.

OK: Continuity (2 ohms or less)

Q: Is the check result normal?

4.STEP 4. Check harness between throttle body assembly connector terminal number 3 and ECM connector terminal number 33.

Check ground line for open circuit and damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.5.STEP 5. Check harness between throttle body assembly connector terminal number 5 and ECM connector terminal number 32.

Check power supply line for open/short circuit. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.6.STEP 6. Using scan tool (M.U.T.-III SE), check the data list.

Use scan tool (M.U.T.-III SE) to check the data list (Refer to DATA LIST REFERENCE TABLE ).

). Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

).

).

).- Item number 90: TPS (Main)

Q: Is the check result normal?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

).7.STEP 7. Check harness between throttle body assembly connector terminal number 5 and ECM connector terminal number 32.

Check power supply line for damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.8.STEP 8. Check harness between throttle body assembly connector terminal number 4 and ECM connector terminal number 43.

Check output line for open circuit and damage. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.9.STEP 9. Using scan tool (M.U.T.-III SE), check the data list.

Use scan tool (M.U.T.-III SE) to check the data list (Refer to DATA LIST REFERENCE TABLE ).

). Replace the throttle body assembly (Refer to THROTTLE BODY ASSEMBLY

Replace the throttle body assembly (Refer to THROTTLE BODY ASSEMBLY ). Then

). Then

).

).- Item number 90: TPS (Main)

Q: Is the check result normal?

Replace the throttle body assembly (Refer to THROTTLE BODY ASSEMBLY

Replace the throttle body assembly (Refer to THROTTLE BODY ASSEMBLY ). Then

). Then

10.STEP 10. Test the OBD-II drive cycle.

After erasing the DTC, carry out test drive with the drive cycle pattern, and recheck the DTC. Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).

(1) Use scan tool (M.U.T.-III SE) to erase the DTC.

(2) Carry out test drive with the drive cycle pattern (Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 1 OBD- II DRIVE CYCLE ).

).

).

).(3) Use scan tool (M.U.T.-III SE) to recheck the DTC.

Q: Is DTC P0123-00 set?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).11.STEP 11. Test the OBD-II drive cycle.

After erasing the DTC, carry out test drive with the drive cycle pattern, and recheck the DTC. Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). The inspection is complete.

The inspection is complete.

(1) Use scan tool (M.U.T.-III SE) to erase the DTC.

(2) Carry out test drive with the drive cycle pattern (Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 1 OBD- II DRIVE CYCLE ).

).

).

).(3) Use scan tool (M.U.T.-III SE) to recheck the DTC.

Q: Is DTC P0123-00 set?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). The inspection is complete.

The inspection is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)