DTC C1073: Faulty motor drive circuit

OPERATION

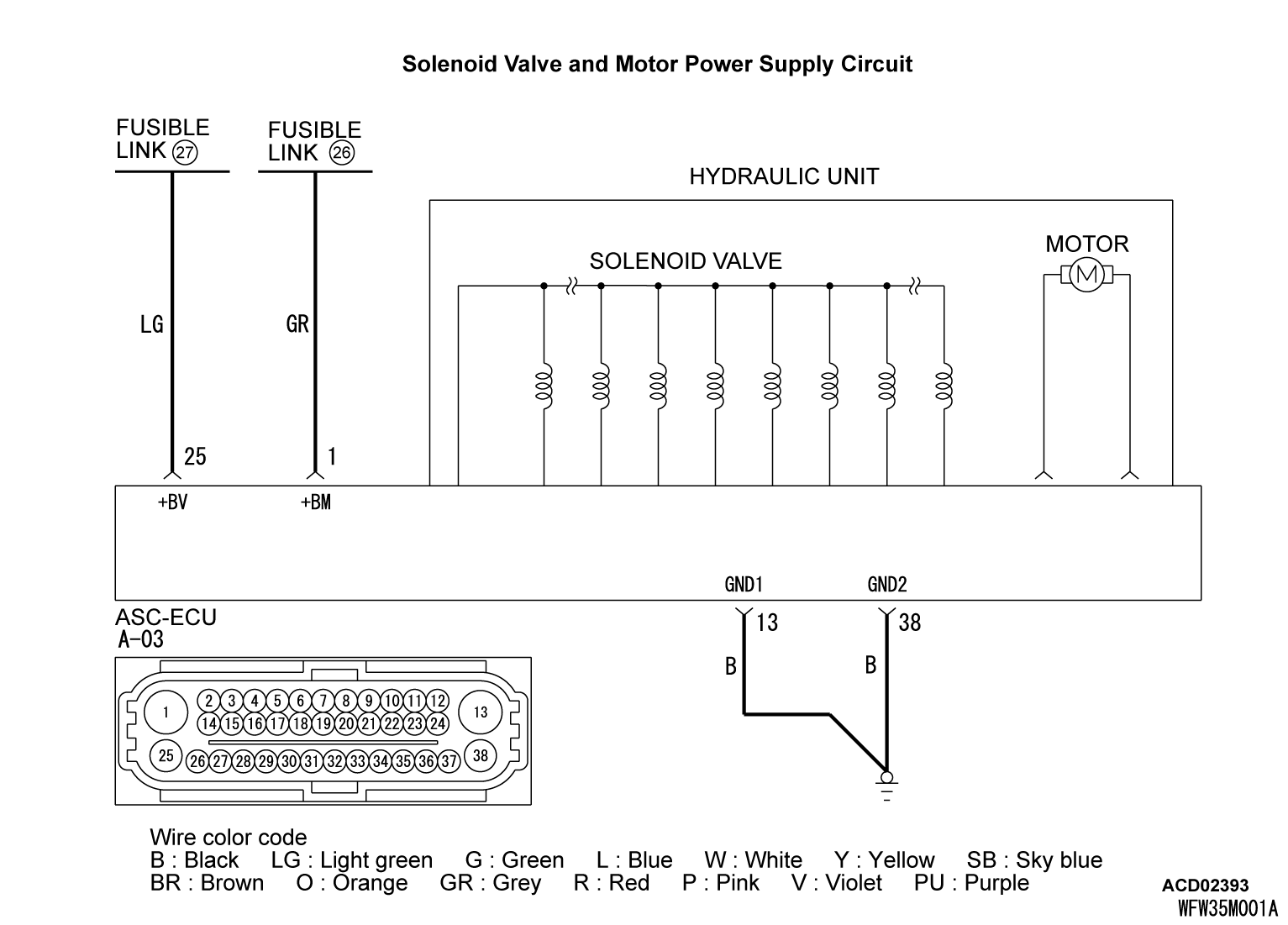

- ASC-ECU contains the power supply circuit (terminal No. 1) for the pump motor. The pump motor is energized by the motor switch, which is incorporated in ASC-ECU.

- The pump motor switch, which is incorporated in ASC-ECU, is always off unless the motor and solenoid valve check is activated when the vehicle is started.

- ASC-ECU activates the pump motor by turning on the ECU built-in pump motor switch.

DTC SET CONDITIONS

If the pump motor switch voltage drop indicates high value when the pump motor operates or after the operation, the pump motor operation is stopped and this diagnostic trouble code is stored.

PROBABLE CAUSES

Current trouble

- Fusible link malfunction

- Damaged wiring harness and connectors

- Abnormality in battery or generator

- ASC-ECU malfunction

Past trouble

- Carry out diagnosis with particular emphasis on wiring harness and connector failures between the power supply circuit (A-03 ASC-ECU connector terminal No.1) to the ASC-ECU motor and the ground circuit (A-03 ASC-ECU connector terminals No.13 and 38). For diagnosis procedures, refer to How to treat past trouble (Refer to GROUP 00 - How to Use Troubleshooting/How to Treat Past Trouble

).

).

DIAGNOSIS

STEP 1. Using scan tool MB991958, diagnose the CAN bus lines.

Use scan tool to diagnose the CAN bus lines.

Is the check result normal?

STEP 2. DTC recheck after resetting CAN bus lines

STEP 4. Charging system check

Refer to GROUP 16 - On-vehicle Service/Output Current Test  .

.

.

.Is the charging system in good condition?

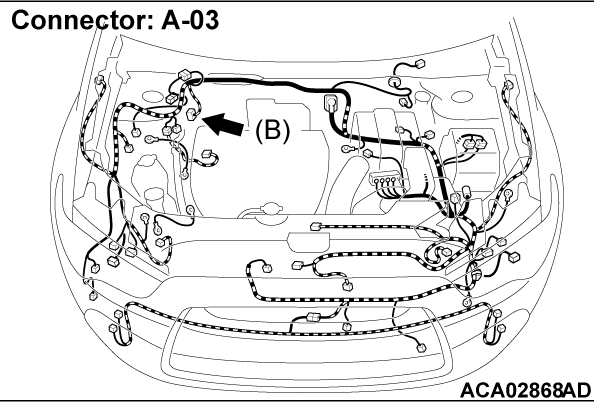

STEP 5. Connector check: A-03 ASC-ECU connector

STEP 6. Fusible link check: Check the fusible link No.26.

Visually check for open circuit in the fusible link No.26.

Is the check result normal?

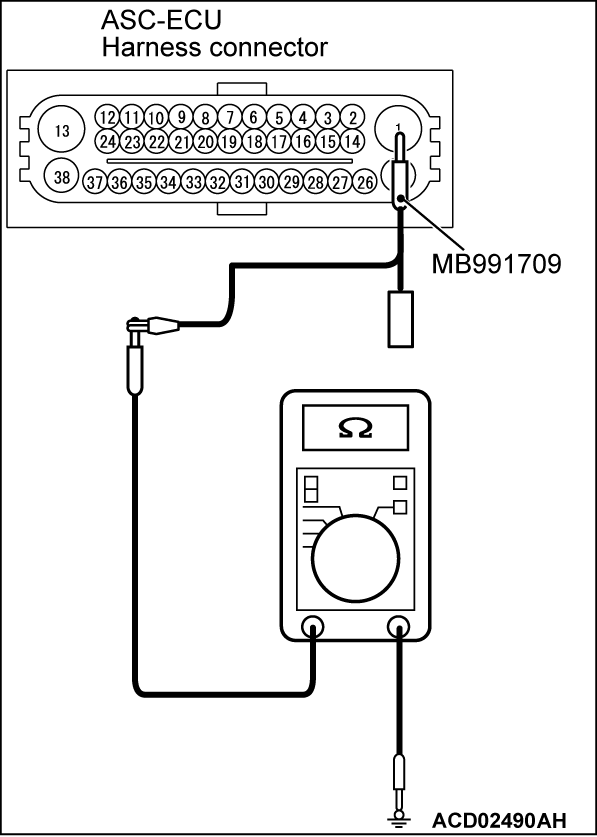

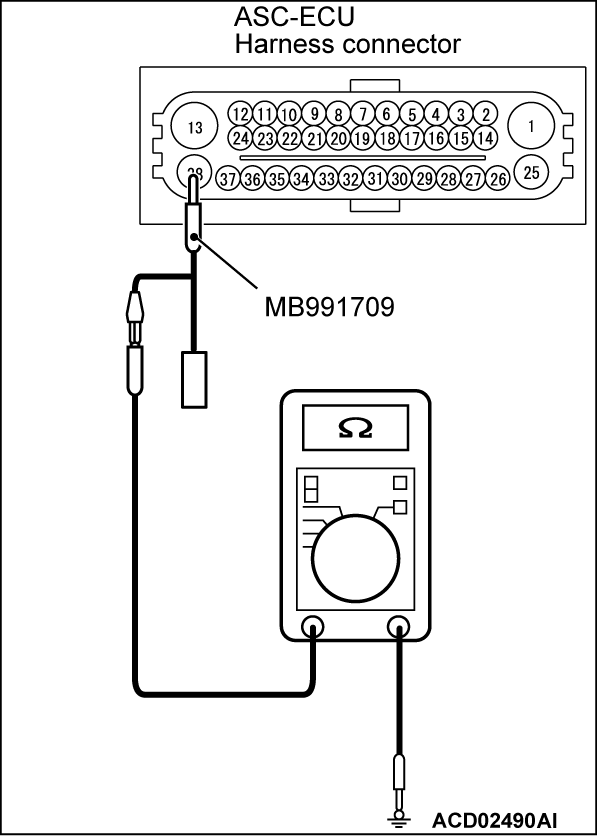

STEP 7. Resistance measurement at A-03 ASC-ECU connector

(1) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the resistance at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(2) Disconnect the fusible link No.26.

(3) Measure the resistance between the terminal No.1 and the body ground.

OK: No continuity

Is the check result normal?

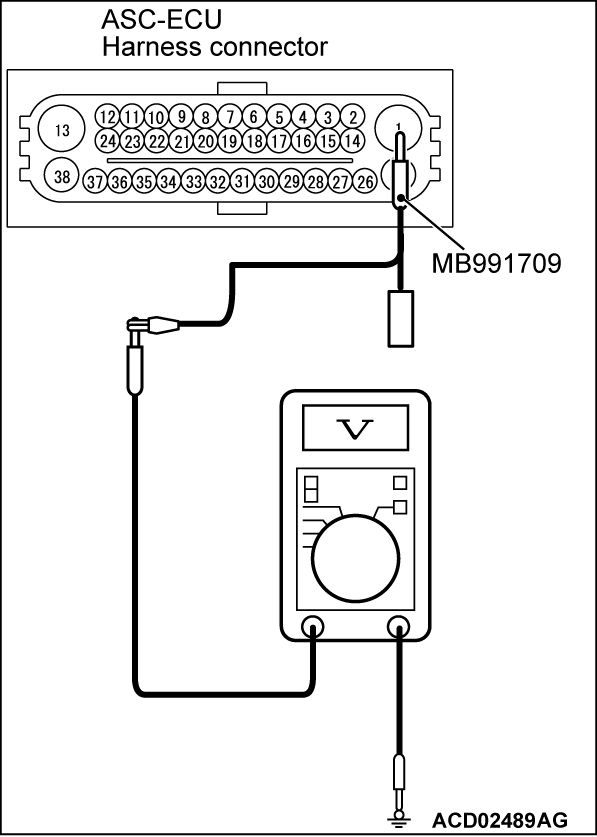

STEP 8. Voltage measurement at the A-03 ASC-ECU connector

(1) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the voltage at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(2) Measure the voltage between the terminal No.1 and the body ground.

OK: Approximately system voltage

Is the check result normal?

STEP 9. Resistance measurement at A-03 ASC-ECU connector

(1) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the resistance at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(2) Measure the resistance between the terminal No.13 and the body ground, and between the terminal No.38 and the body ground.

OK: Continuity exists (2 Ω or less)

Is the check result normal?

STEP 10. Check whether the DTC is stored again.

(1) Erase the DTC.

(2) Drive the vehicle at 12 mph (20 km/h) or higher.

| note | The ABS warning light does not turn OFF in some cases unless the vehicle runs at 12 mph (20 km/h) or higher. |

Is DTC C1073?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)