DTC P1D08: Load Connection Abnormal

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Battery charger control module (OBC) monitor

- EV CAN monitor

Sensor (The sensor below is determined to be normal)

- Not applicable

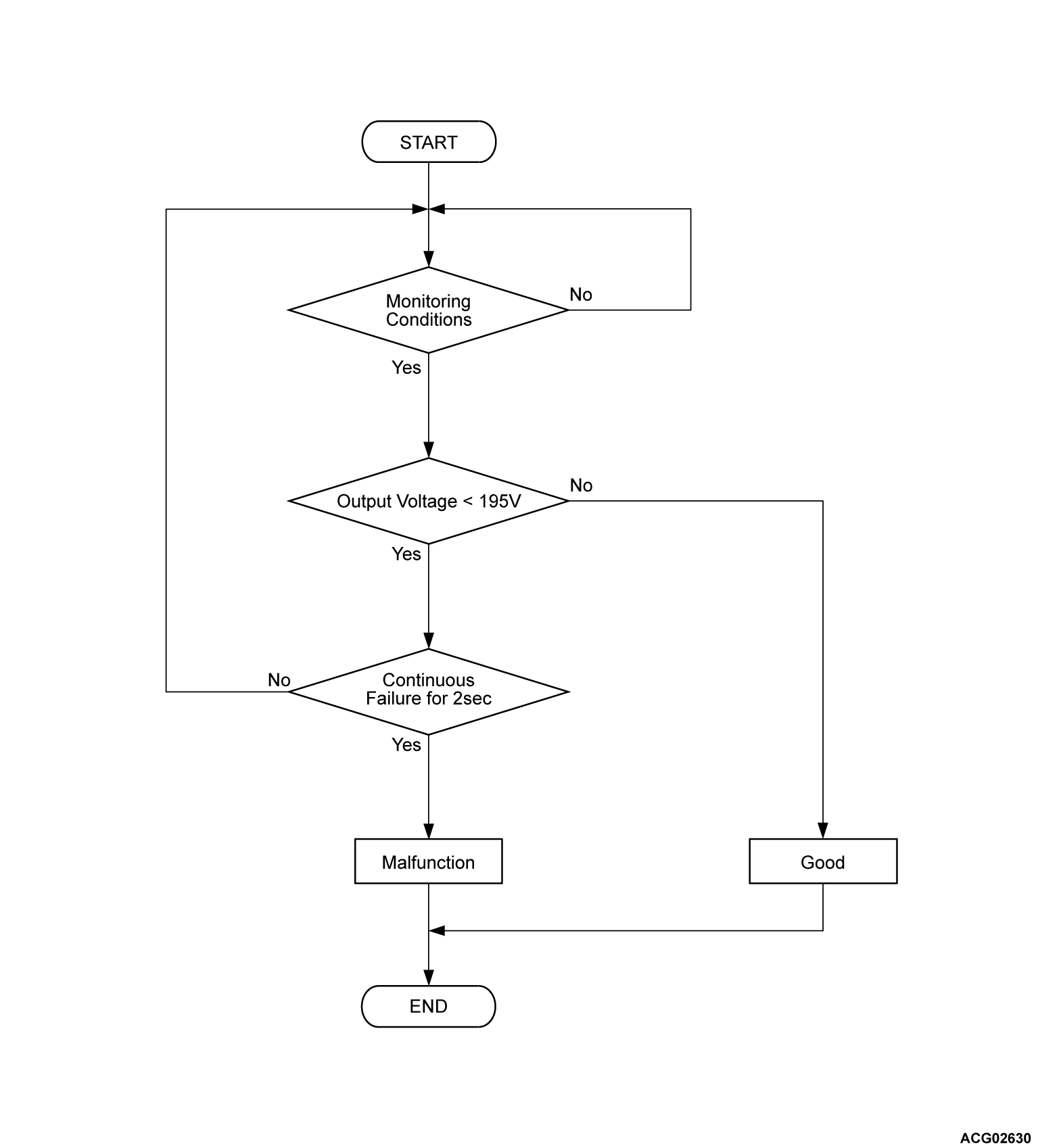

DTC SET CONDITIONS

Check Conditions

- The EV system or the charging system is activated or the charge permission from PHEV-ECU is on.

Judgment Criterion

- Change of the output voltage is more than 195 volts for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- The charge is stopped.

PROBABLE CAUSES

- Open circuit or harness damage in high voltage circuits between on board charger/DC-DC converter and drive battery, or loose connector contact.

- The high voltage fuse is melted down inside the REMCU.

- The on board charger/DC-DC converter is failed

DIAGNOSIS

Required Special Tools

- MB991223: Wiring harness set

- MB992006: Extra fine probe

| danger | When high voltage system components are served, be sure to pull service plugs to shut down high voltage (Refer to  ). ). |

| danger | When pulling service plugs, wear the specified protective equipment (Refer to  ). ). |

STEP 1. Using scan tool (M.U.T.-IIISE), check whether the other system DTC is set.

STEP 2. Perform the continuity check of the high voltage fuse inside the REMCU.

Check of the high-voltage fuse inside inverter (Refer to GROUP 54Db - Check and Replacement of the High-voltage Fuse inside the Inverter  ).

).

).

).Is the check result normal?

STEP 3. Check of open circuit and damage in P line and N line between on board charger/DC-DC converter connector and drive battery connector.

Is the check result normal?

STEP 4. Test the OBD-II drive cycle.

(2) Check the DTC.

Is the DTC set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)