DTC P1D61: BATT.CHGR Temperature Sensor Characteristic Abnormal

DTC P1D64: BATT.CHGR PFC Temperature sensor Short to Ground

DTC P1D65: BATT.CHGR PFC Temperature sensor Short to Power Supply

DTC P1D66: BATT. CHGR Inverter Temperature Sensor Short to Ground

DTC P1D67: BATT. CHGR Inverter Temperature Sensor Short to Power Supply

DTC P1D68: BATT. CHGR Inverter Temperature Sensor Short to Ground 2

DTC P1D69: BATT. CHGR Inverter Temperature Sensor Short to Power Supply 2

DTC P1D64: BATT.CHGR PFC Temperature sensor Short to Ground

DTC P1D65: BATT.CHGR PFC Temperature sensor Short to Power Supply

DTC P1D66: BATT. CHGR Inverter Temperature Sensor Short to Ground

DTC P1D67: BATT. CHGR Inverter Temperature Sensor Short to Power Supply

DTC P1D68: BATT. CHGR Inverter Temperature Sensor Short to Ground 2

DTC P1D69: BATT. CHGR Inverter Temperature Sensor Short to Power Supply 2

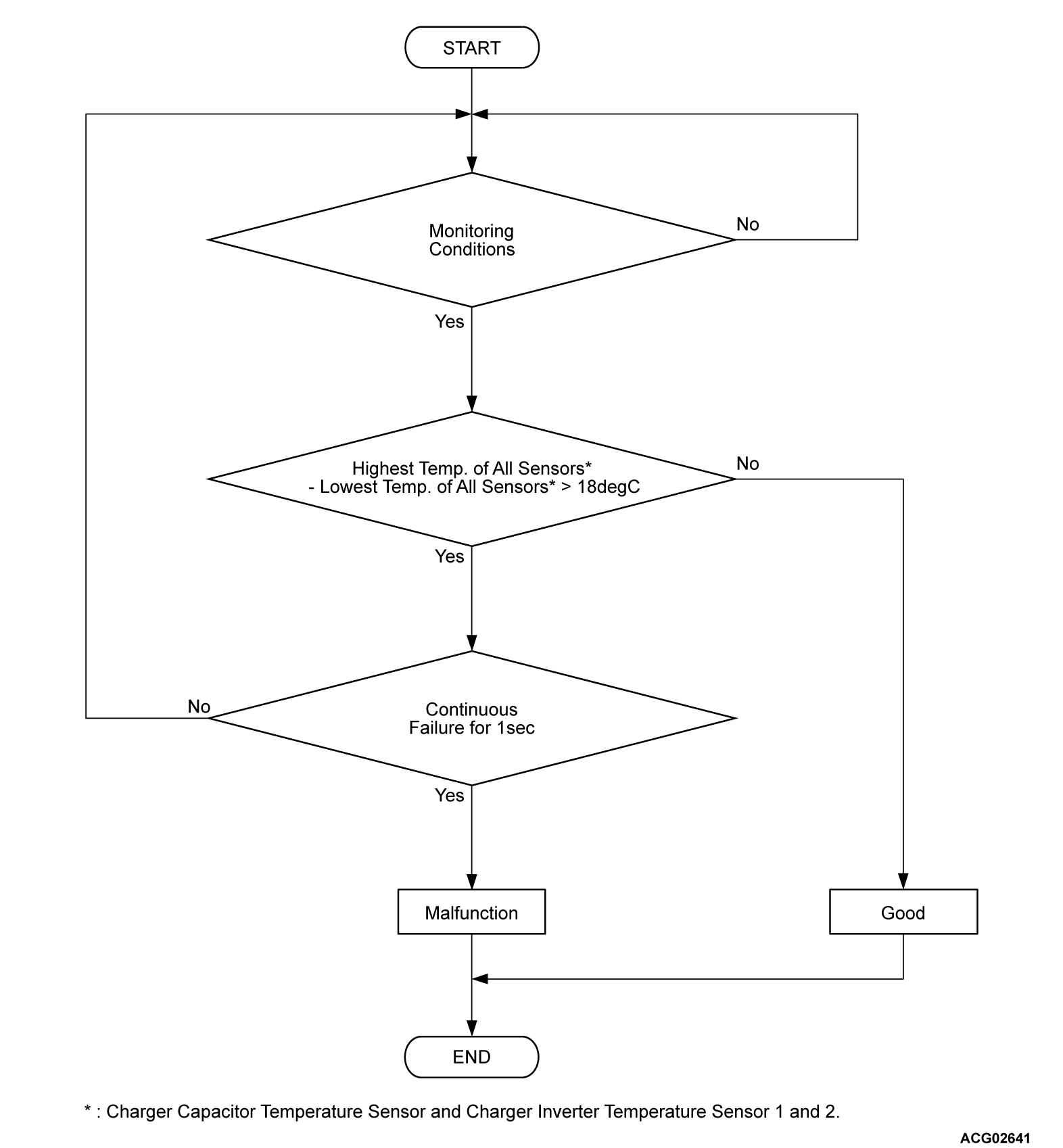

DESCRIPTIONS OF MONITOR METHODS <DTC P1D61>

3 temperature sensors (charger capacitor temperature sensor, charger inverter temperature sensor 1, charger inverter temperature sensor 2) are monitored by comparing the maximum and minimum temperature of these sensors.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Battery charger control module (OBC) monitor

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions <DTC P1D61>

- OBC power supply voltage is 10 volts to 16 volts.

- Charge permission from PHEV-ECU is off.

- Time after above condition satisfied is more than 240 seconds.

Judgment Criterion <DTC P1D61>

- When the difference between the value of the highest temperature of all sensors and the value of the lowest temperature of all sensors remains at 64°F (18°C) or less for 1 second

note All sensor: Charger capacitor temperature sensor, charger inverter temperature sensor 1 and charger inverter temperature sensor 2

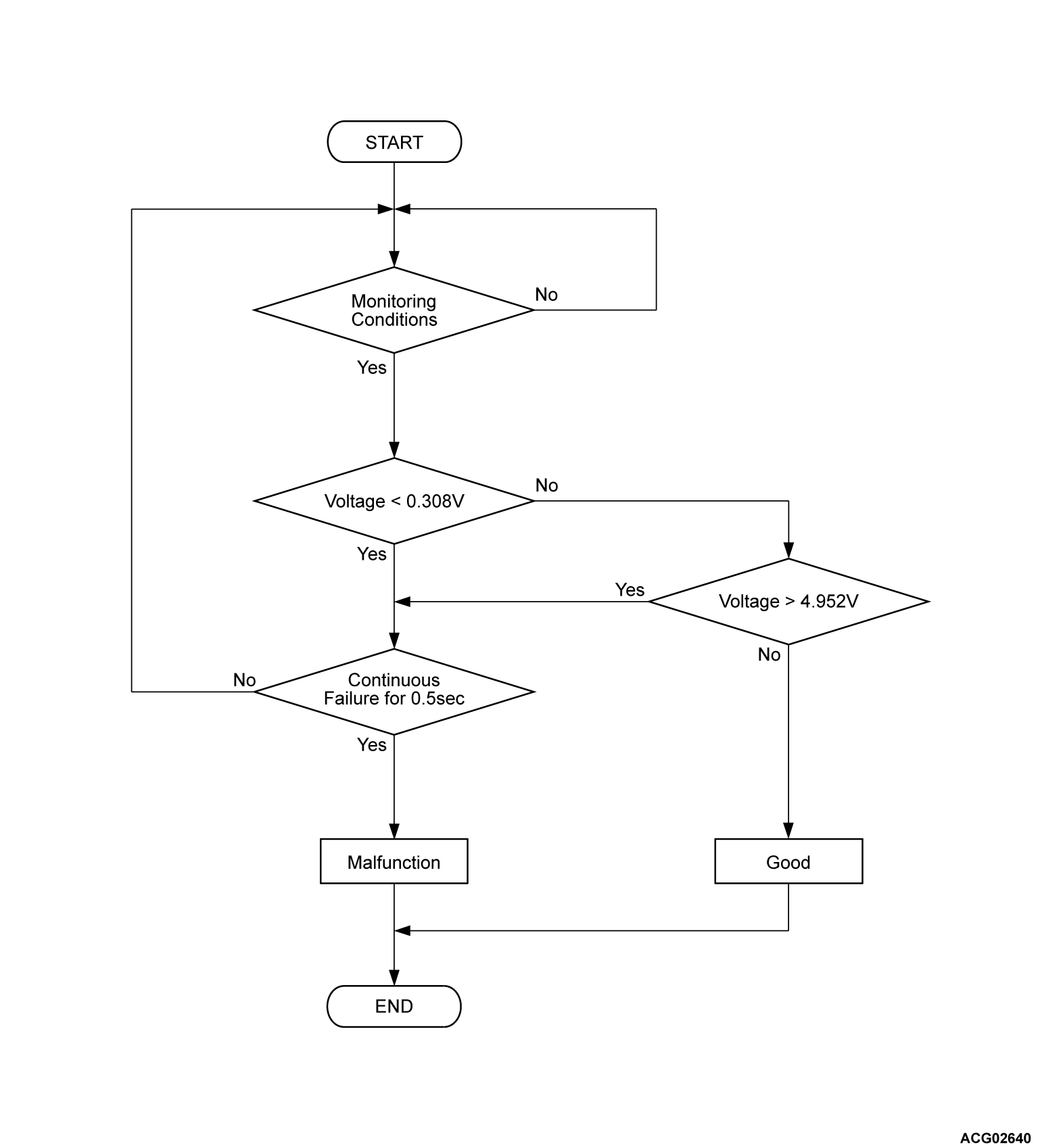

Check Conditions <DTC P1D64, P1D65, P1D66, P1D67, P1D68, P1D69>

- OBC power supply voltage is 10 volts to 16 volts.

Judgment Criterion <DTC P1D64, P1D66, P1D68>

- Change of the charger temperature sensor voltage is less than 0.308 volt [more than 302°F (150°C)] for 0.5 second.

Judgment Criterion <DTC P1D65, P1D67, P1D69>

- Change of the charger temperature sensor voltage is more than 4.952 volts [less than -61°F (-52°C)] for 0.5 second.

OBD-II DRIVE CYCLE PATTERN <DTC P1D61>

FAIL-SAFE AND BACKUP FUNCTION

- The charge is stopped.

PROBABLE CAUSES

- The cooling system is failed.

- The on board charger/DC-DC converter is failed.

DIAGNOSIS

STEP 1. Using scan tool (M.U.T.-IIISE), check on board charger/DC-DC converter data list.

Are the check result normal?

STEP 2. Check the cooling system.

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)