DTC P0C04: Overcurrent in motor

DTC P10CF: Three-phase line fails

DTC P10CF: Three-phase line fails

| danger |

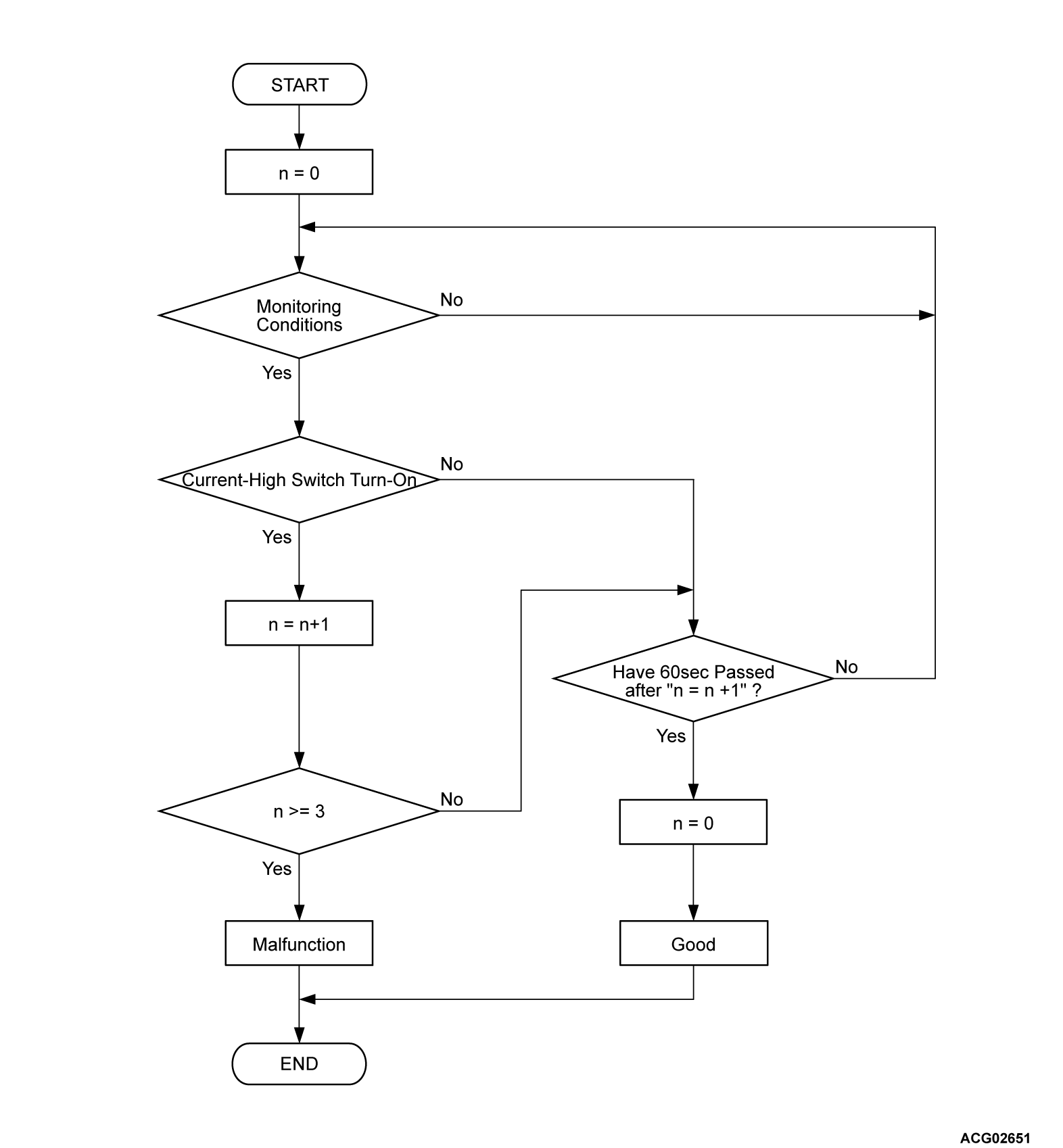

DESCRIPTIONS OF MONITOR METHODS <DTC P0C04>

- V and W-phase coil current is directly measured while U-phase current is calculated.

- When the maximum of three phase current exceeds 700 ampere the IGBT will temporarily shutdown for 0.2 second.

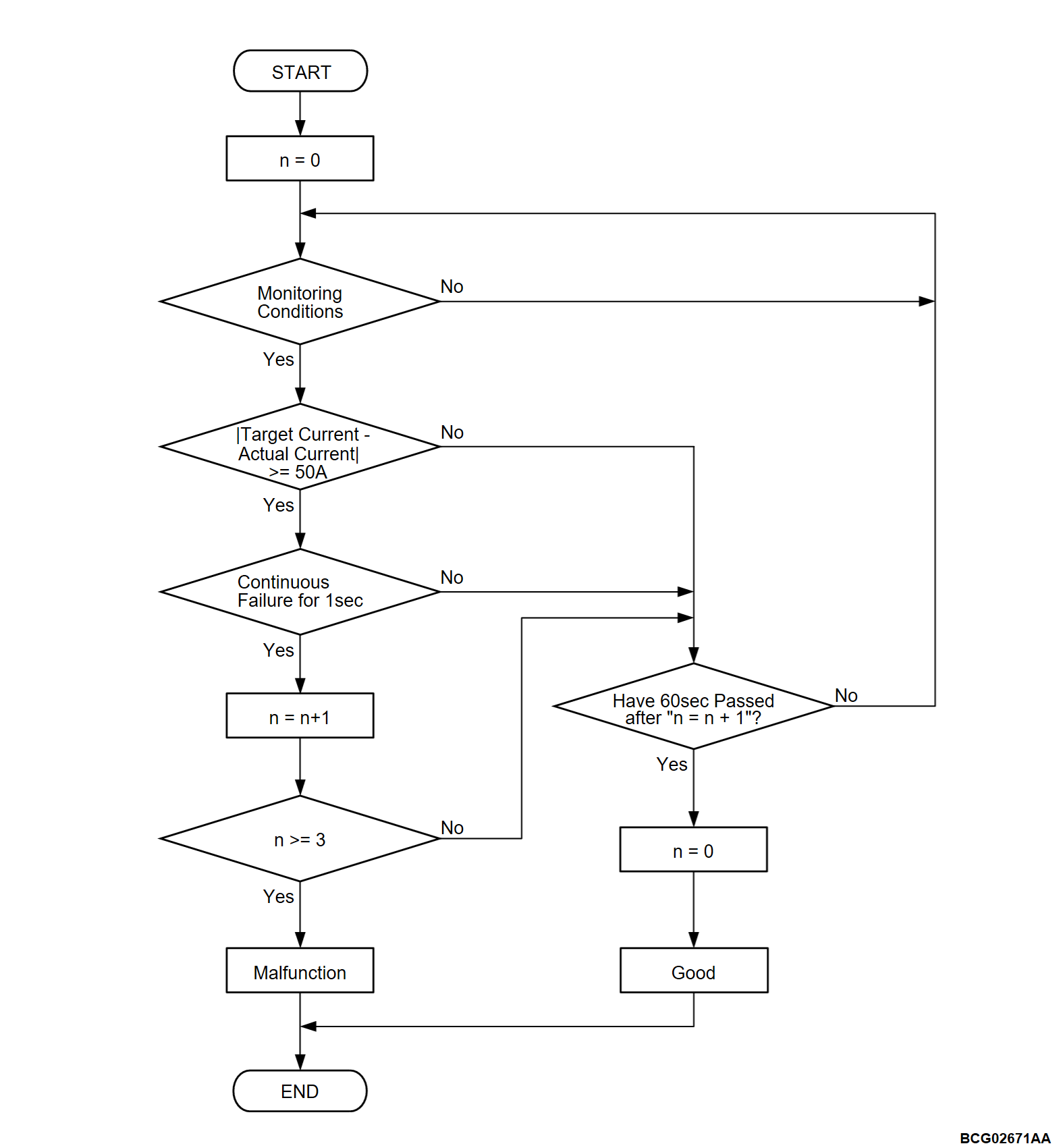

DESCRIPTIONS OF MONITOR METHODS <DTC P10CF>

- V and W-phase coil current is directly measured and compared to the target current.

- An open/short circuit in the three phase motor is detected by comparing actual current of V-phase and W-phase of each motor to the target current which is calculated from the PHEV-ECU torque request.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions <DTC P0C04>

- The IGBT status of REMCU is on (Active).

Judgment Criterion <DTC P0C04>

- The drive motor current-high switch is turned ON 3 times within 60 seconds.

Check Conditions <DTC P10CF>

- The IGBT status of REMCU is on (Active).

Judgment Criterion <DTC P10CF>

- The absolute value of the difference between the value of target current and the value of actual current is 50 amperes or more for 3 times within 60 seconds.

PROBABLE CAUSES

- Three-phase wire in the high-voltage wiring harness fails

- Malfunction of the rear motor/rear transaxle assembly

- Malfunction of the REMCU

- Resolver wiring harness fails

DIAGNOSIS

Required Special Tools

- MB991223: Wiring harness set

- MB992006: Extra fine probe

STEP 1. Using scan tool (M.U.T.-IIISE), check whether the DTC is set.

Check if the DTC P0A45 is set in the REMCU.

Is the DTC set?

STEP 2. Check the rear motor assembly.

Drive the vehicle to check whether there is abnormal sound or rotation trouble in the rear motor.

Is the check result normal?

STEP 3. Check the high-voltage terminal.

| danger |

|

(2) Check that the following cable (REMCU side) is tightened to the specified torque.

Is the check result normal?

STEP 4. Check the high-voltage terminal.

| danger |

|

Check that the following cable (rear motor side) is tightened to the specified torque.

Is the check result normal?

STEP 5. Check the REMCU connector

Check the REMCU connector (S1 line, S2 line, S3 line, S4 line, R1 line and R2 line) visually for semi-fitting, damage, moisture/foreign matter intrusion.

Is the check result normal?

: Replace the wiring harness (S1 line, S2 line, S3 line, S4 line, R1 line and R2 line). Then go to Step 9 .

.

.

.STEP 6. Resolver resistance check

(1) Disconnect the REMCU connector.

(2) Measure the resistance between the rear motor connector terminals.

|

Is the check result normal?

STEP 7. Resistance measurement between the REMCU connector and the rear motor assembly connector (S1 line, S2 line, S3 line, S4 line, R1 line and R2 line)

(1) Remove the wiring harness (S1 line, S2 line, S3 line, S4 line, R1 line and R2 line).

(2) Check the continuity of wring harness (S1 line, S2 line, S3 line, S4 line, R1 line and R2 line).

OK: Continuity exists (2 Ω or less)

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)