REMOVAL AND INSTALLATION

| danger | When servicing the high-voltage system parts, be sure to wear the specified protection equipment and disconnect the service plug to interrupt the high-voltage supply (Refer to  ). ). |

| caution |

|

REMOVAL SERVICE POINTS

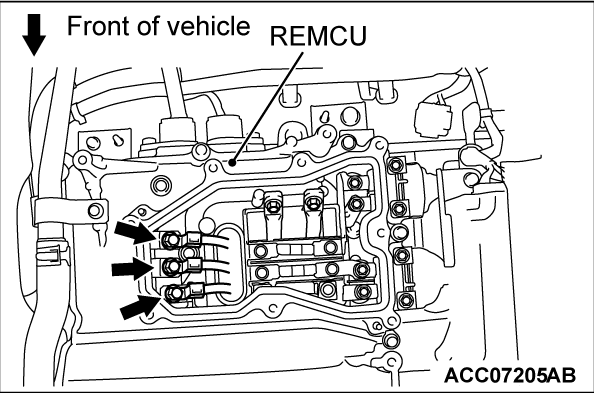

<<A>> REAR MOTOR CABLE DISCONNECTION

1. Remove the inner cable mounting bolts (3 locations).

2. Remove the outer cable mounting bolts (2 locations).

3. Pull out the cable from the REMCU.

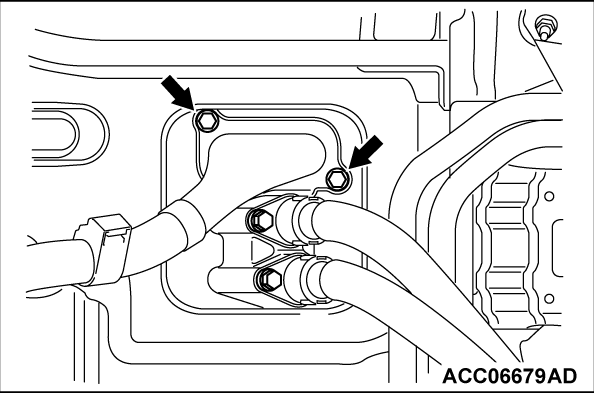

<<B>> WATER HOSES S AND R DISCONNECTION

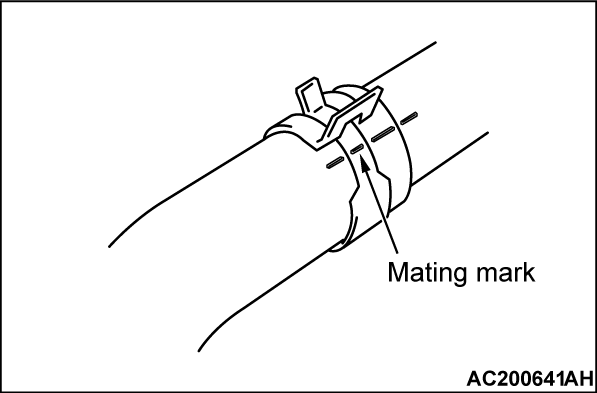

Put a mating mark before removal as shown in the figure in order to assemble the hose and hose clips to the original positions.

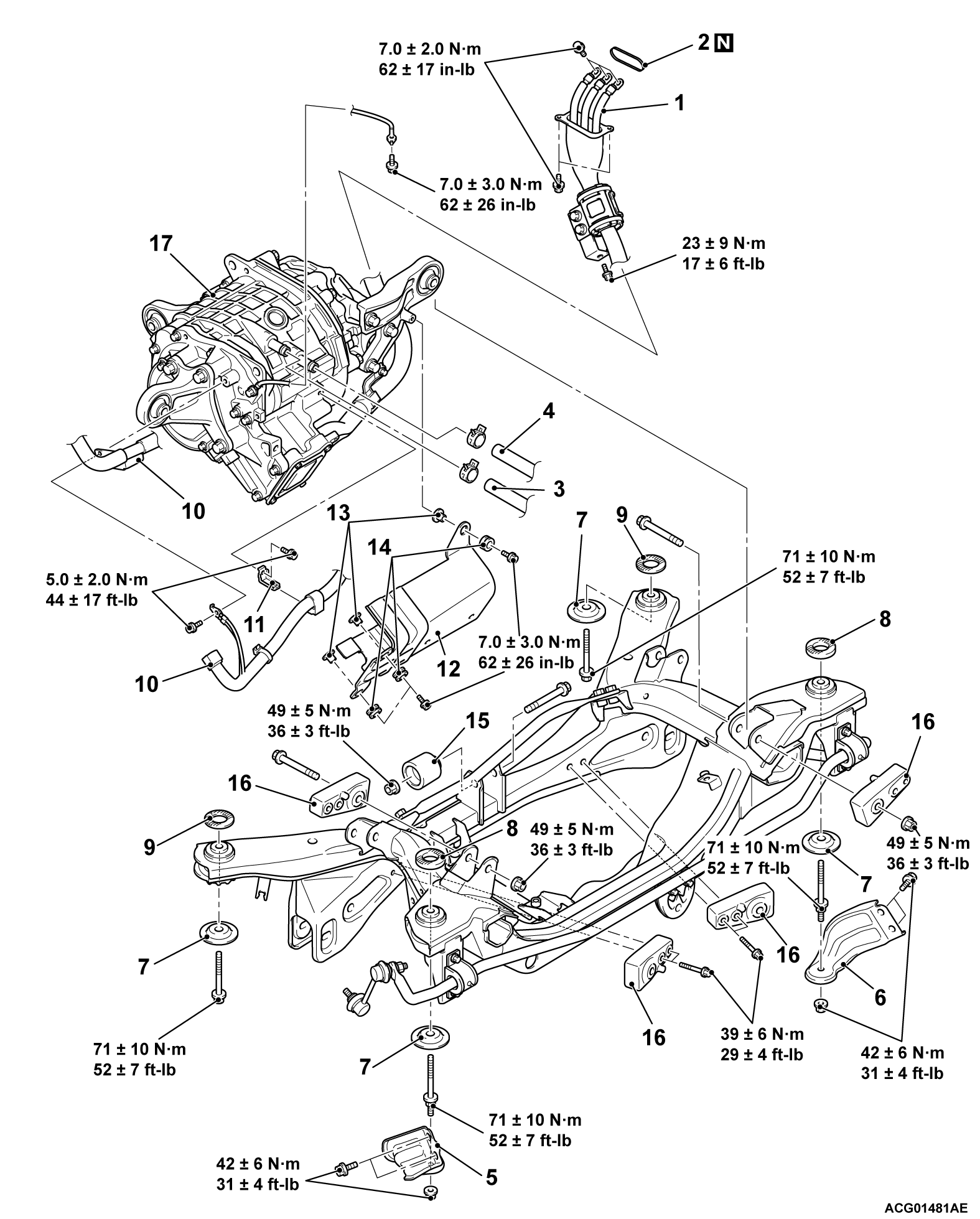

<<C>> REAR MOTOR/REAR TRANSAXLE ASSEMBLY REMOVAL

1. Support the rear motor/rear transaxle assembly with a transmission jack. Remove the flange nut, the rear eye stay rear (LH), the rear eye stay rear (RH), the flange bolt, the lower stopper and the stopper.

2. Check that the hoses and wiring harness wires are not trapped. Then remove the rear motor/rear transaxle assembly with the rear motor mounting front bracket assembly, the rear motor mounting rear (LH and RH) bracket assembly attached.

INSTALLATION SERVICE POINT

>>A<< WATER HOSES S AND R CONNECTION

1. Insert the hose to each pipe up to the convex portion.

2. Align the mating marks on the hose and hose clips and install the hose without twisting the hose.

>>B<< REAR MOTOR CABLE CONNECTION

1. Connect the cable with the REMCU.

2. Install the outer cable mounting bolts and inner cable mounting bolts in this order and tighten them to the specified torque.

Tightening torque: 7.0 ± 2.0 N·m (62 ± 17 in-lb)

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)