DTC P1167: Inverter gate driver fails

| danger |

DESCRIPTIONS OF MONITOR METHODS

- Overcurrent of the IGBT drive circuit or power supply voltage reduction of the IGBT drive circuit.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

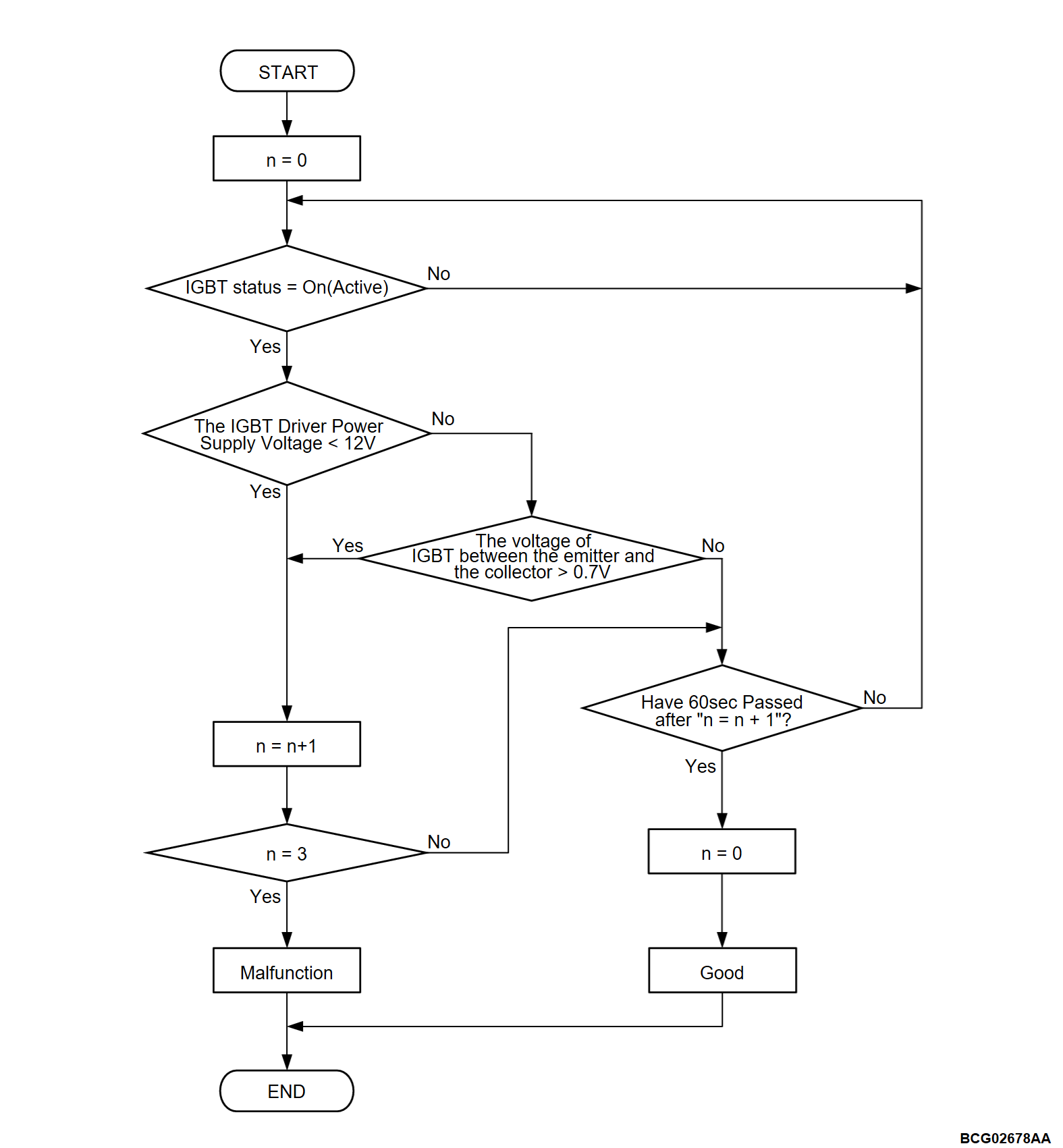

DTC SET CONDITIONS

Check Conditions

- The IGBT status of power drive unit (FEMCU) is on (Active).

Judgment Criterion

- IGBT driver power supply voltage less than 12 volts occurs 3 times within 60 seconds.

- A voltage excess of 0.7 volts between the collector and the emitter occurs 3 times within 60 seconds.

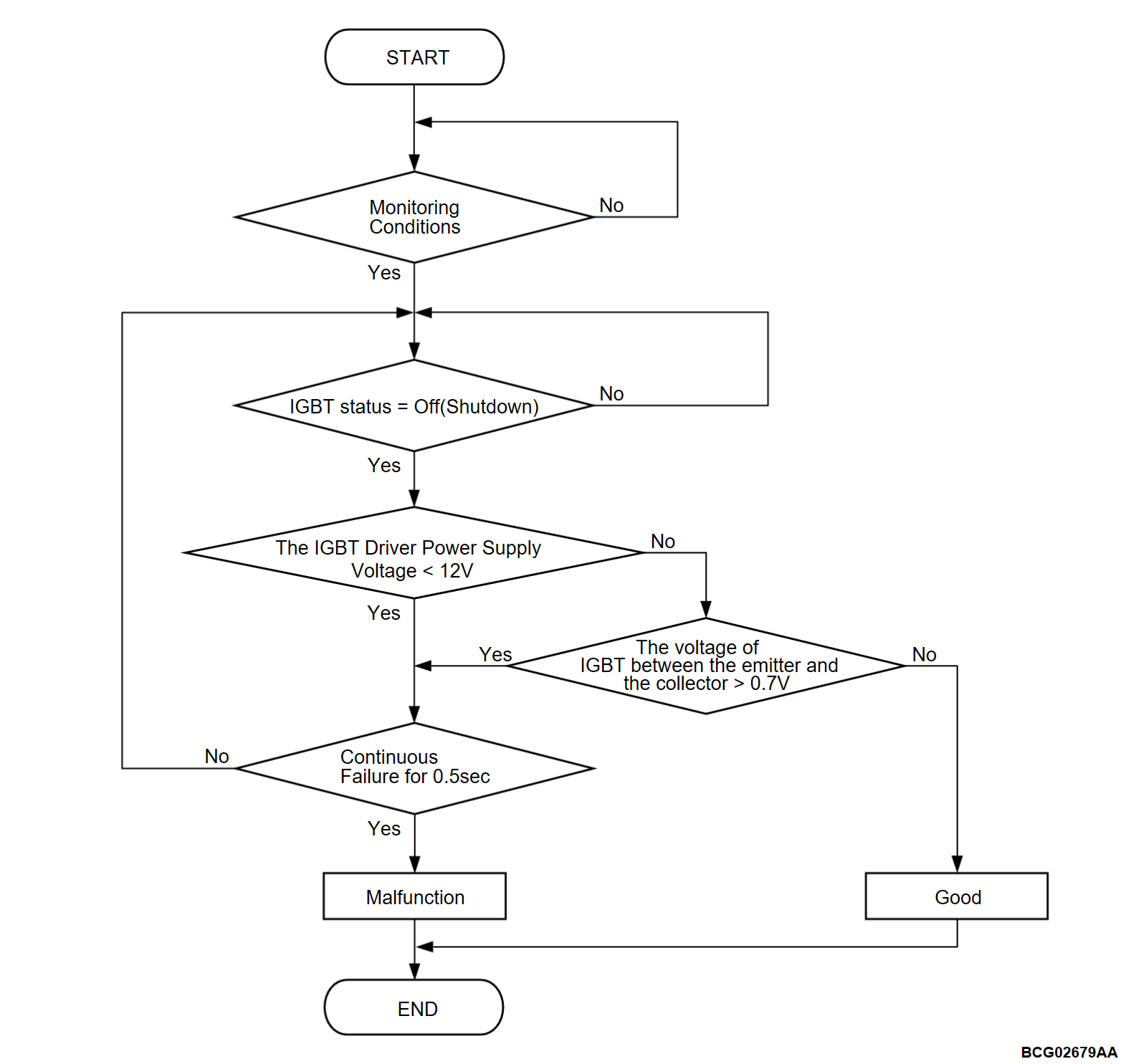

DTC SET CONDITIONS

Check Conditions

- Power drive unit (FEMCU) power supply voltage is 8 volts to 16 volts.

- The IGBT status of power drive unit (FEMCU) is off (Shutdown).

Judgment Criterion

- IGBT driver power supply voltage is less than 12 volts for 0.5 seconds.

- The voltage between the collector and the emitter is exceeded by 0.7 volts for 0.5 seconds.

PROBABLE CAUSES

- Malfunction of the power drive unit (FEMCU)

- Malfunction of the front motor high-voltage terminal

- Malfunction of the front motor assembly

DIAGNOSIS

STEP 1. Check the high-voltage terminal.

| danger |

|

(2) Check that the following cable is tightened to the specified torque.

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)