DTC P1160: Motor coil U-phase temperature sensor fails (range)

DTC P1161: Motor coil W-phase temperature sensor fails (range)

DTC P1161: Motor coil W-phase temperature sensor fails (range)

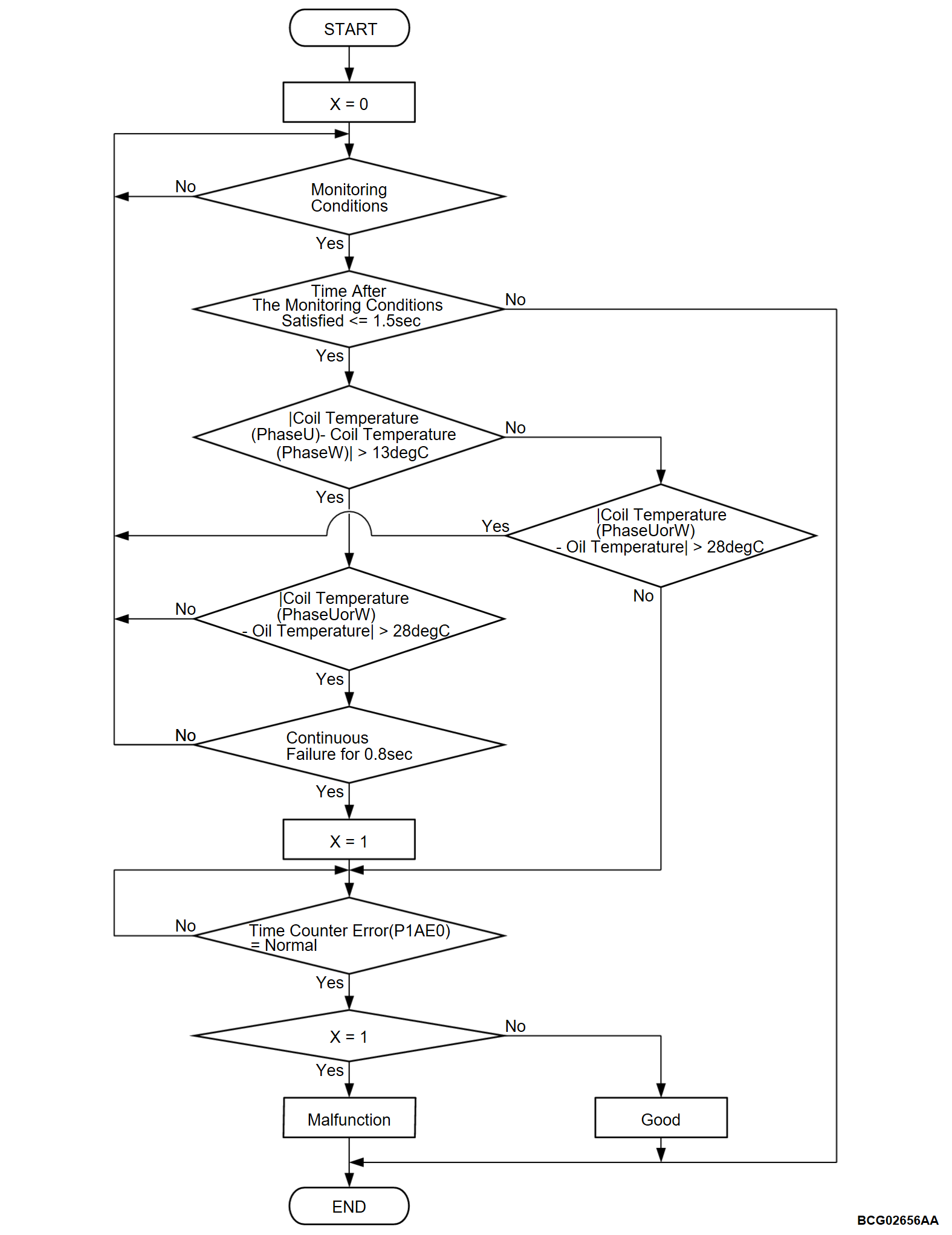

DESCRIPTIONS OF MONITOR METHODS

- Oil temperature, front drive motor coil temperature and generator coil temperature are monitored by the starter generator control module and front drive motor control module.

- Oil temperature, U-phase coil temperature and W-phase coil temperature are compared to each other after IGBT status off (shutdown) and a minimum one hour soak.

MONITOR EXECUTION

- Once per driving cycle

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Non-volatile random access memory monitor

- EV CAN monitor

- Battery energy control module (sub BMU) monitor

Sensor (The sensor below is determined to be normal)

- Drive motor oil temperature sensor

DTC SET CONDITIONS

Check Conditions

- Power drive unit (FEMCU) power supply voltage is 8 volts to 16 volts.

- Time after above conditions satisfy is less than 1.5 seconds.

- The soaking time is more than 3,600 seconds.

- The IGBT status of power drive unit (FEMCU) is off (Shutdown).

Judgment Criterion

- The absolute value of the difference between the value of U-phase coil temperature and W-phase coil temperature remains 13°C (55°F) or more in 0.8 seconds.

- The absolute value of the difference between the value of U-phase or W-phase coil temperature and the oil temperature remains 28°C (82°F) or more in 0.8 seconds.

PROBABLE CAUSES

- The temperature sensor circuit fails

- Malfunction of the front motor assembly

- Malfunction of the generator

- Malfunction of the power drive unit (FEMCU)

DIAGNOSIS

Required Special Tools

- MB991223: Wiring harness set

- MB992006: Extra fine probe

STEP 1. Using scan tool (M.U.T.-IIISE), check whether the DTC is set.

Check if the DTC P1A3D is set in the power drive unit (FEMCU).

Is the DTC set?

STEP 2. Check the resistance in the coil temperature sensor.

(1) Disconnect the power drive unit connector.

(2) Check the conduction of the harness between the power drive unit and the front motor and measure the resistance value of the coil temperature sensor (U-phase and W-phase) in the power drive unit connector terminals.

|

Is the check result normal?

STEP 3. Check the resistance in the oil temperature sensor.

Check the conduction of the harness between the power drive unit and the generator and measure the resistance value of the oil temperature sensor in the power drive unit connector terminals.

|

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)