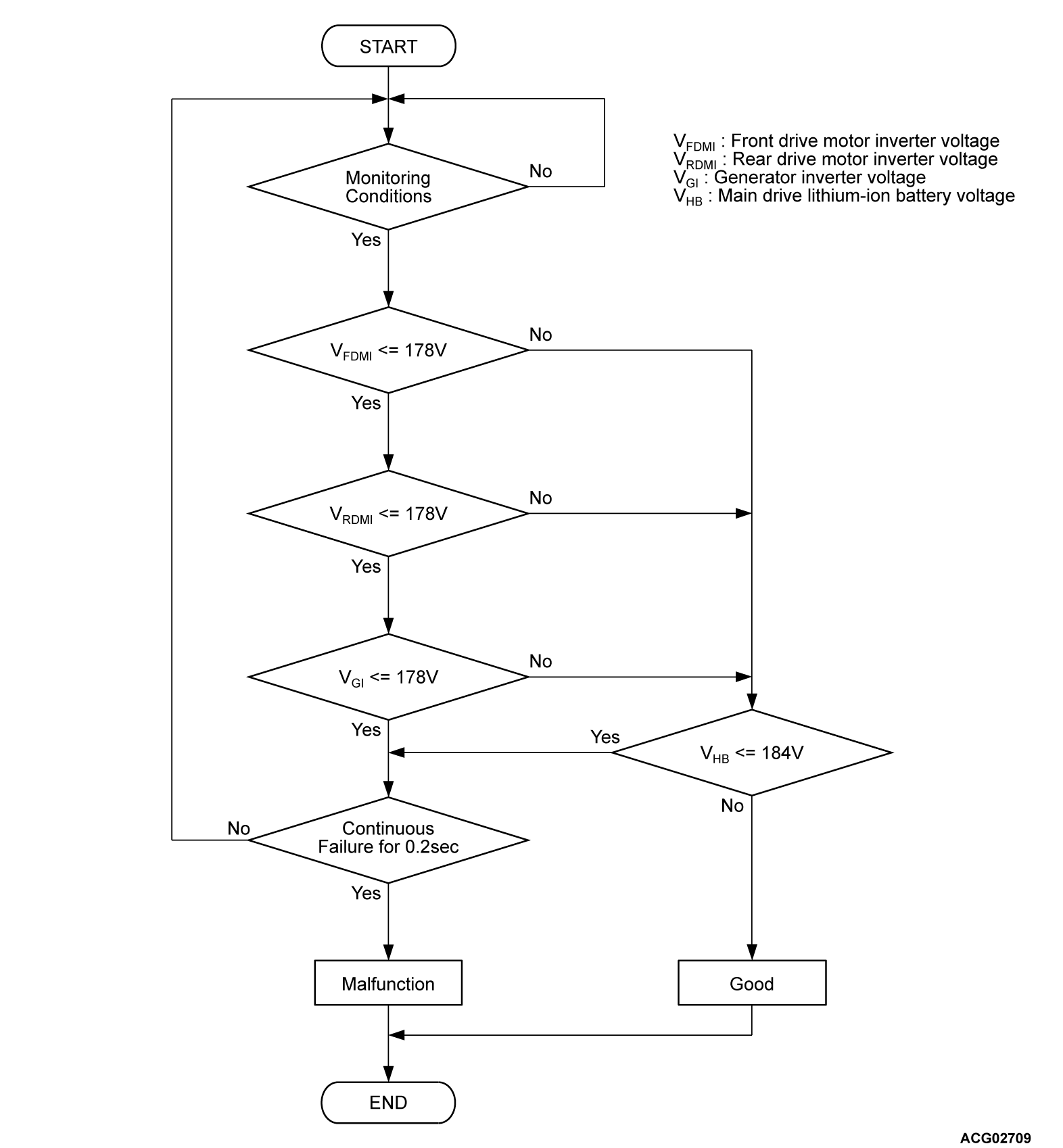

DTC P0AFA: Hybrid battery voltage low

| danger |

| caution | If there is any problem in the CAN bus lines, an incorrect DTC may be set. Prior to this diagnosis, diagnose the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnostics Table  ). ). |

MONITOR EXECUTION

Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- EV-CAN monitor

- Main drive lithium-ion battery voltage sense circuit monitor

- Battery-CAN monitor

- Front electric motor control unit (FEMCU) inverter voltage monitor

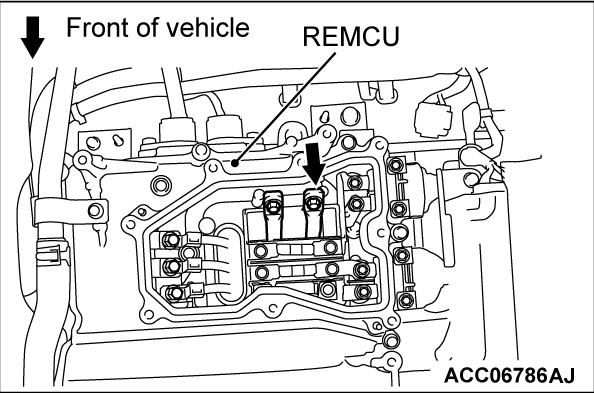

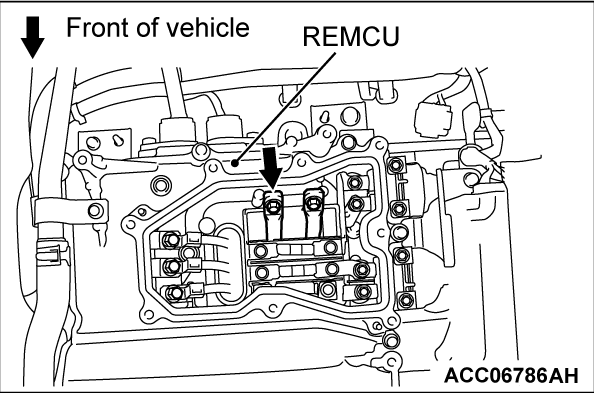

- Rear electric motor control unit (REMCU) inverter voltage monitor

- Generator control unit (GCU) inverter voltage monitor

Sensor (The sensor below is determined to be normal)

- Front electric motor control unit (FEMCU) inverter voltage sensor

- Rear electric motor control unit (REMCU) inverter voltage sensor

- Generator control unit (GCU) inverter voltage sensor

Check Conditions

- When the vehicle is in the charging mode

Judgment Criterion

- When a state with the voltage of each condenser (built in the FEMCU, GCU and REMCU) being 178 volts or less continues for 0.2 seconds while the main drive lithium-ion battery is being charged

- When a state with the voltage of the main drive lithium-ion battery being 184 volts or less continues for 0.2 seconds while the main drive lithium-ion battery is being charged

PROBABLE CAUSES

- The high-voltage circuit fails.

- Blown high-voltage fuse.

- Main contactor energization circuit fails.

- Malfunction of the power drive unit (FEMCU).

- Malfunction of the main contactor.

DIAGNOSIS

Required Special Tools

- MB991223: Wiring harness set

- MB992006: Extra fine probe

STEP 1. Using scan tool (M.U.T.-IIISE), check whether the other DTC is set.

Check if DTC P0C78 is set in the PHEV-ECU.

Is the DTC set?

STEP 2. Check the wiring harness for open circuit (PHEV-ECU connector and the main drive lithium-ion battery connector)

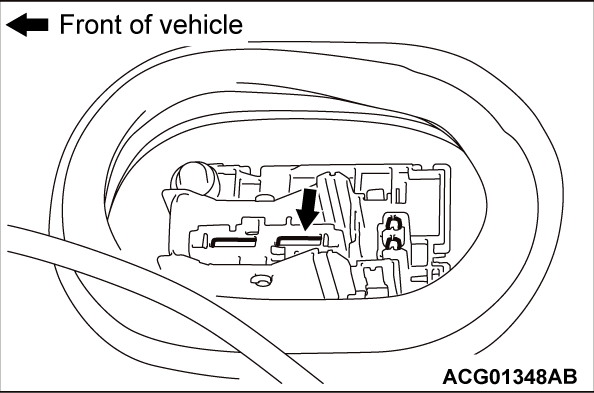

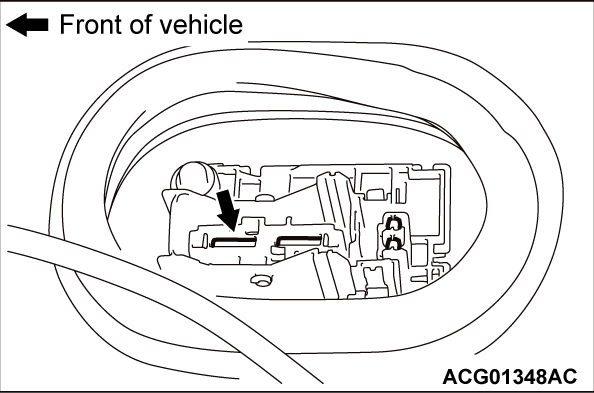

Check the wiring harness between PHEV-ECU connector (terminal CNT+) and the main drive lithium-ion battery connector (terminal No.6).

Is the check result normal?

STEP 3. Check the wiring harness for damage between D-33 main drive lithium-ion battery connector (terminal No.4) and the body ground.

STEP 4. Check the main drive lithium-ion battery main contactor (P) and (N) <On-vehicles check>.

Check resistance of main contactor (P) and (N) coil with harness connector (Refer to GROUP 54Dc - On-vehicles Service, Check on Coil Resistance of Contactor  ).

).

).

).Is the check result normal?

STEP 5. Check the high-voltage fuse.

| danger |

|

Is the check result normal?

STEP 6. Check the high-voltage circuit.

| danger |

|

Check whether the high-voltage wiring harness is connect securely or damaged.

Is the check result normal?

STEP 7. Check the high-voltage circuit.

| danger |

|

(2) Apply a voltage of 12 volts to the CNT- terminal to turn on the charging contactor.

(3) Connect a high-voltage compatible multimeter between the main drive lithium-ion battery high-voltage terminal (REMCU) and the main drive lithium-ion battery service plug rear terminal.

OK: Approximately 100 - 164 volts

(4) Apply a voltage of 12 volts to the CNTP terminal to turn on the charging contactor.

(5) Connect a high-voltage compatible multimeter between the main drive lithium-ion battery high-voltage terminal (REMCU) and the main drive lithium-ion battery service plug front terminal.

OK: Approximately 100 - 164 volts

(6) Apply a voltage of 12 volts to the CNT+ terminal to turn on the charging contactor.

(7) Connect a high-voltage compatible multimeter between the main drive lithium-ion battery high-voltage terminal (REMCU) and the main drive lithium-ion battery service plug front terminal.

OK: Approximately 100 - 164 volts

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)