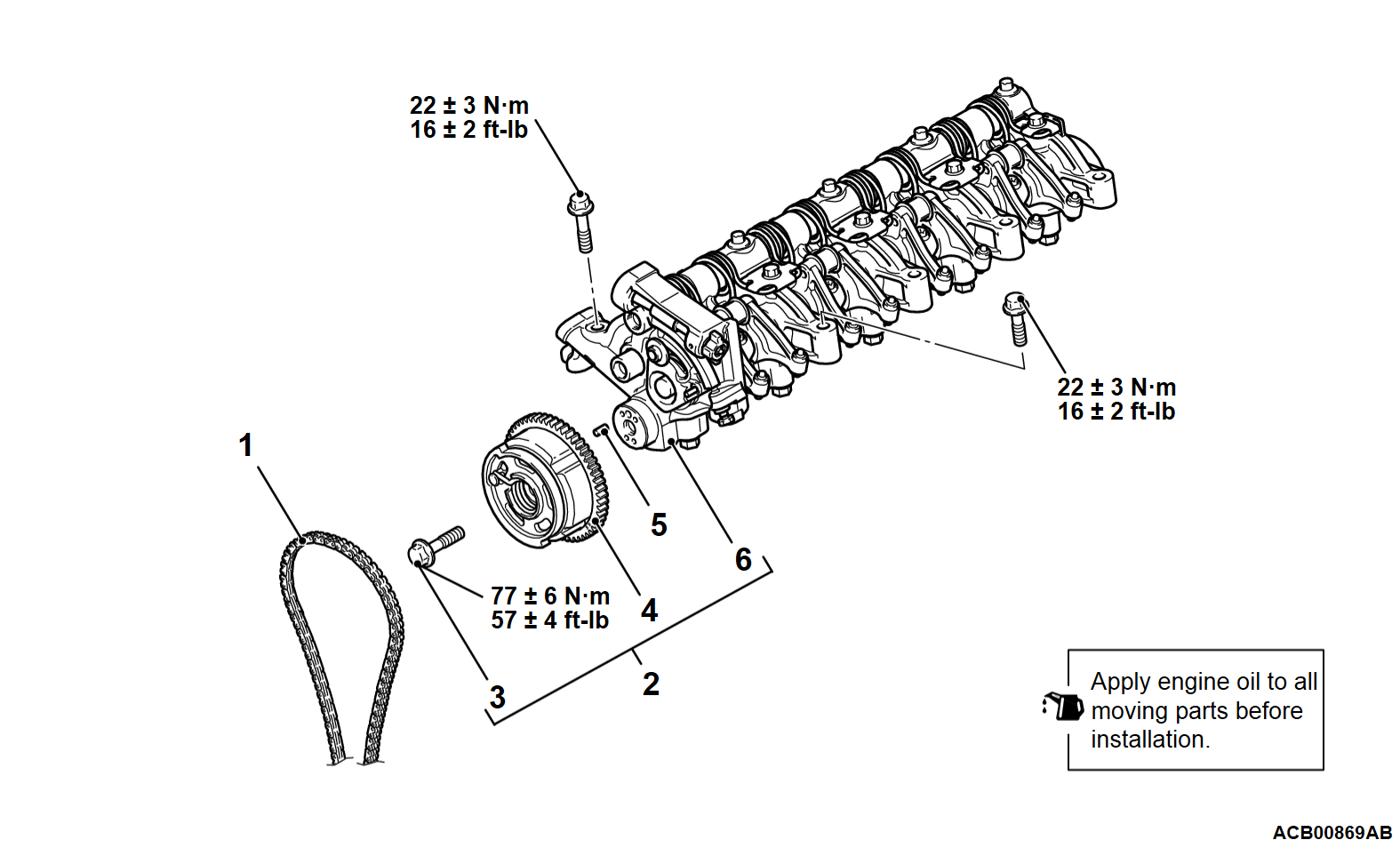

REMOVAL AND INSTALLATION

Pre-removal operation | Post-installation operation |

| note | Do not remove the dowel pin. When it must be assembled, refer to Service Points of Removal. |

REMOVAL SERVICE POINTS

<<A>> TIMING CHAIN REMOVAL

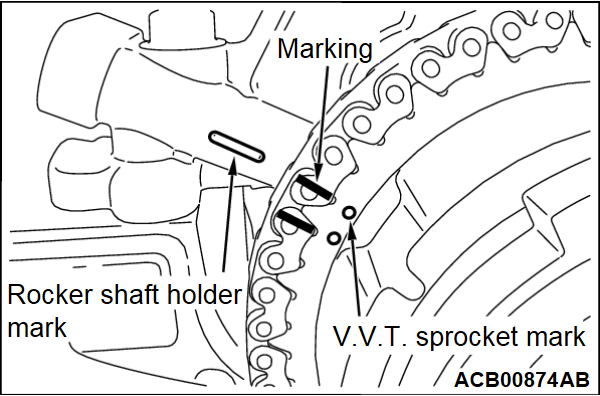

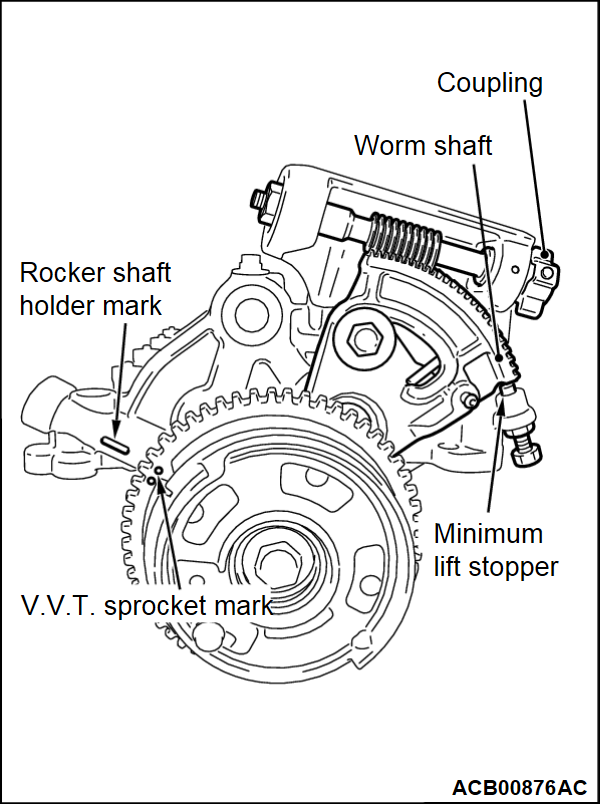

1. Align the mark for removal and installation of the rocker arm and camshaft assembly on the V.V.T. sprocket with the mark on the rocker shaft holder, and then mark the timing chain.

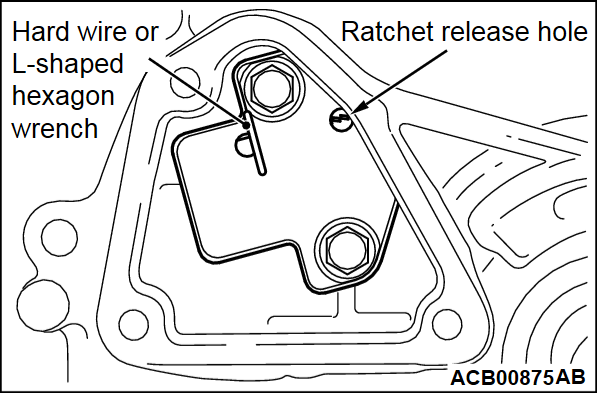

2. Insert a precision flat-tipped screwdriver through the service hole on the timing chain case to release the timing chain tensioner ratchet.

3. While counterholding the crankshaft, tension the timing chain tensioner side of the chain by turning the flats of the camshaft end in direction of engine rotation to compress the plunger.

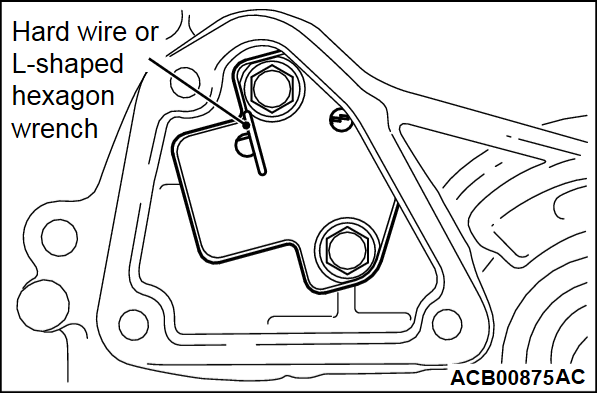

4. Insert hard wire (such as the piano wire) or the L-shaped hexagon wrench [1.5 mm (0.06 inch)] to fix the plunger of the timing chain tensioner.

5.

| caution | Be careful not to drop the timing chain tensioner mounting bolts into the timing chain case. |

Remove the timing chain tensioner.

6. Remove the timing chain from the V.V.T. sprocket.

<<B>> V.V.T. SPROCKET, ROCKER ARM AND CAMSHAFT ASSEMBLY REMOVAL

1.

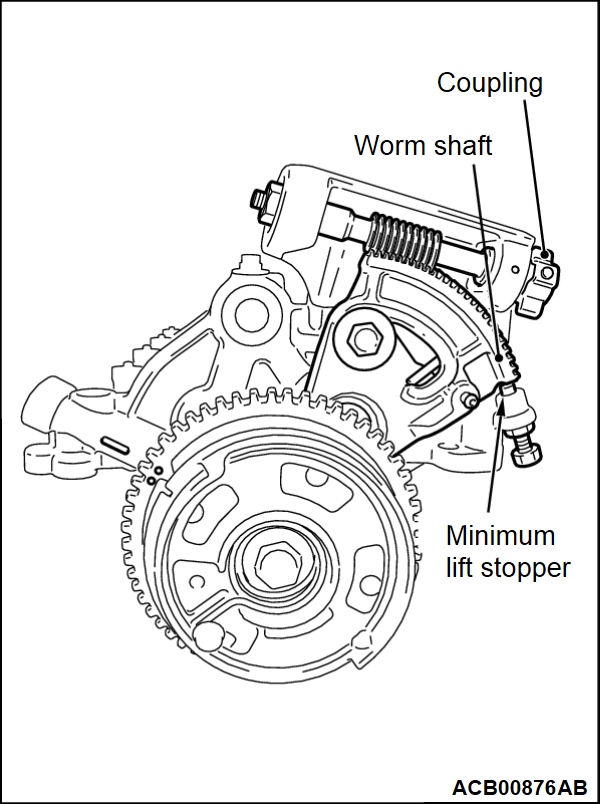

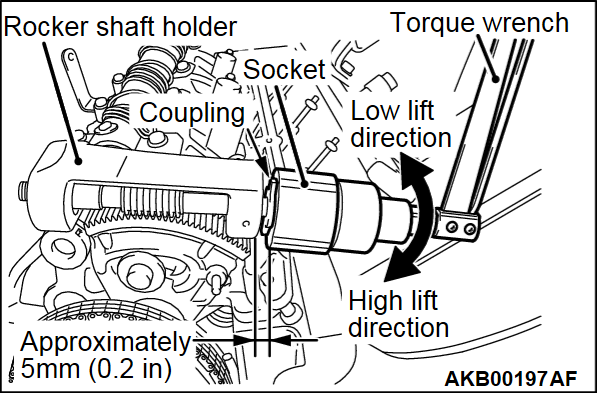

Rotate the coupling clockwise until the worm wheel contacts the minimum lift stopper slightly.

| caution |

|

| note | When rotating the coupling clockwise, the worm wheel should move in the minimum lift direction. When rotating the coupling counterclockwise, the worm wheel should move in the maximum lift direction. |

| note | When rotating the coupling by hand, insert a 12-point socket (24 mm) into the position on the coupling approximately 5 mm (0.2 inch) away from the rocker shaft holder. Then use a small torque wrench to rotate it slowly. |

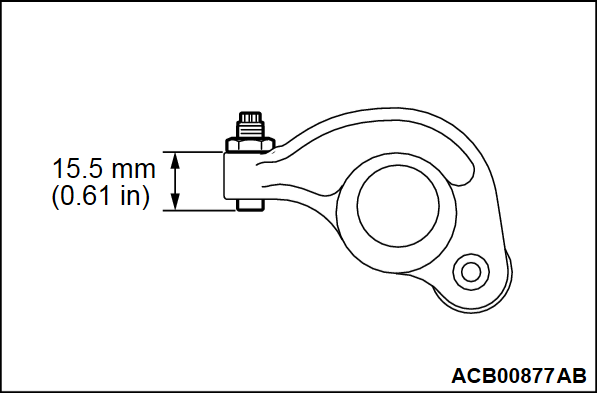

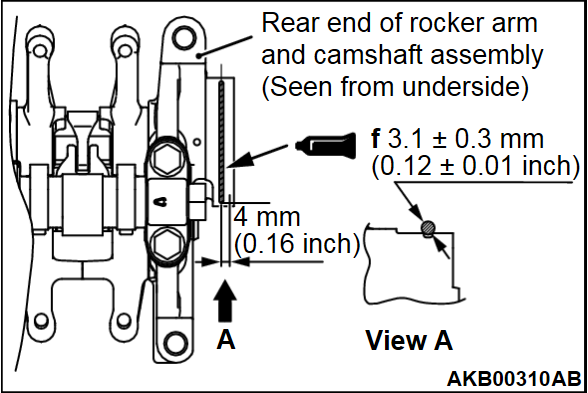

2. Pull down the adjusting screw of the exhaust side rocker arm at least to the shown dimension.

3. Loosen the mounting bolts of the rocker arm and camshaft assembly, and remove them.

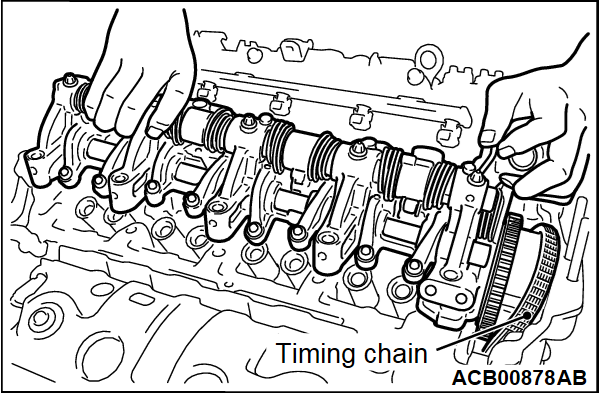

4. Lift off the V.V.T. sprocket, the rocker arm and camshaft assembly from the cylinder head while loosening the timing chain.

INSTALLATION SERVICE POINTS

>>A<< DOWEL PIN / V.V.T. SPROCKET ASSEMBLY / V.V.T. SPROCKET BOLT INSTALLATION

>>B<< V.V.T. SPROCKET, ROCKER ARM AND CAMSHAFT ASSEMBLY INSTALLATION

1. Pull down the adjusting screw of the exhaust side rocker arm at least to the shown dimension.

2.

Rotate the coupling clockwise until the worm wheel contacts the minimum lift stopper slightly.

| caution |

|

| note | When rotating the coupling clockwise, the worm wheel should move in the minimum lift direction. When rotating the coupling counterclockwise, the worm wheel should move in the maximum lift direction. |

| note | When rotating the coupling by hand, insert a 12-point socket (24 mm) into the coupling ca. 5 mm (0.2 inch) away from the rocker shaft holder. Then use a small torque wrench to rotate it slowly. |

3. Align the mark for removal and installation of the rocker arm and camshaft assembly on the V.V.T. sprocket with the mark on the rocker shaft holder.

4. Completely remove the sealant adhering to the cylinder head and the rocker arm/camshaft assembly using a remover or others and degrease the area using a volatile degreasing agent.

5.

Apply sealant to the underside of the rocker arm and camshaft assembly without a gap and immediately install the V.V.T. sprocket, rocker arm and camshaft assembly to the cylinder head.

| caution | The rocker arm and camshaft assembly cannot be installed with the rocker arms hanging down. |

Specified sealant: ThreeBond 1227D or equivalent

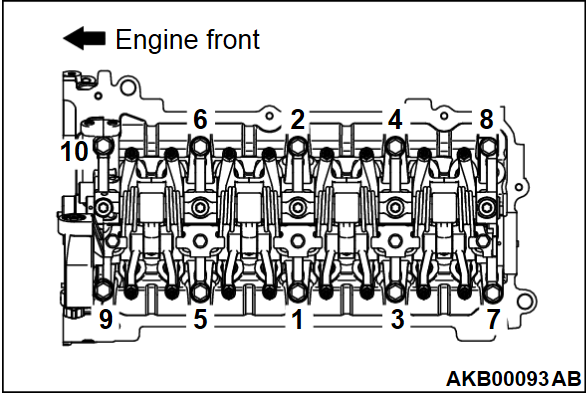

6. Temporarily tighten the mounting bolts of the rocker arm and camshaft assembly to 8.0 N·m (71 in-lb) in the order shown in the figure.

7.

| caution |

|

Tighten the mounting bolts of the rocker arm and camshaft assembly to the specified torque in the order shown in the figure.

Tightening torque: 22 ± 3 N·m (16 ± 2 ft-lb)

>>C<< TIMING CHAIN INSTALLATION

1. Align the timing chain mark made during removal with the mark for removal and installation of the rocker arm and camshaft assembly on the V.V.T. sprocket.

2.

Assemble the timing chain tensioner, and tighten the mounting bolts to the specified torque.

| caution | Be careful not to drop the timing chain tensioner mounting bolts into the timing chain case. |

Tightening torque: 11 ± 3 N·m (97 ± 26 in-lb)

3. Remove the hard wire or L-shaped hexagon wrench fixing the plunger of the timing chain tensioner to apply tension to the timing chain.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)