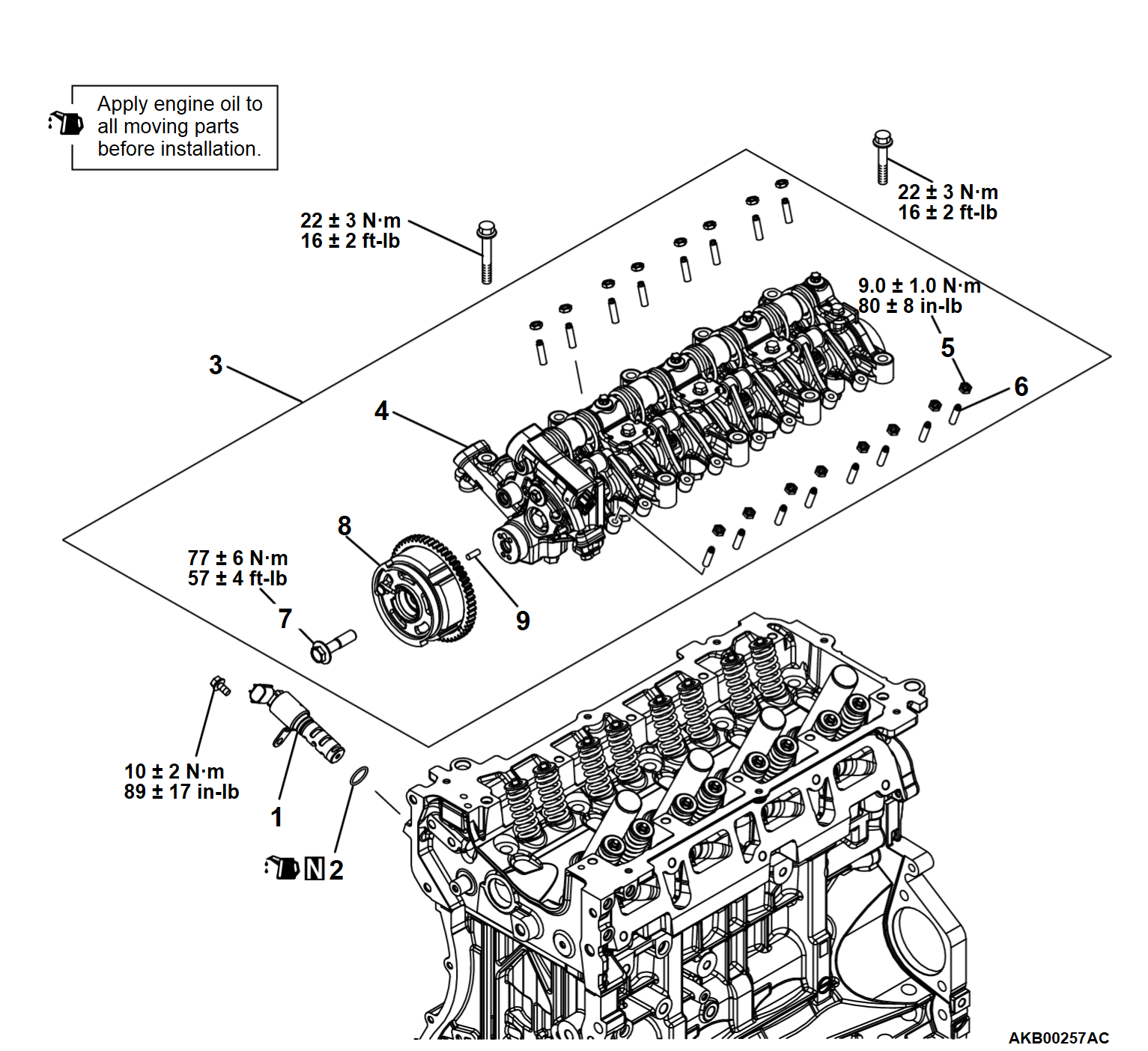

REMOVAL AND INSTALLATION

| caution | Unless specified in this manual, do not overhaul the rocker arm and camshaft assembly. When loosing the bolts other than the bolts installing the rocker arm and camshaft assembly, the adjusted portion at the factory delivery may deviate. Never loosen the bolts. |

| note | Do not remove dowel pin. When you need the installation, refer to the installation points. |

Required Special Tool:

- MB991146: Installer

REMOVAL SERVICE POINTS

<<A>> V.V.T. SPROCKET, ROCKER ARM AND CAMSHAFT ASSEMBLY REMOVAL

1.

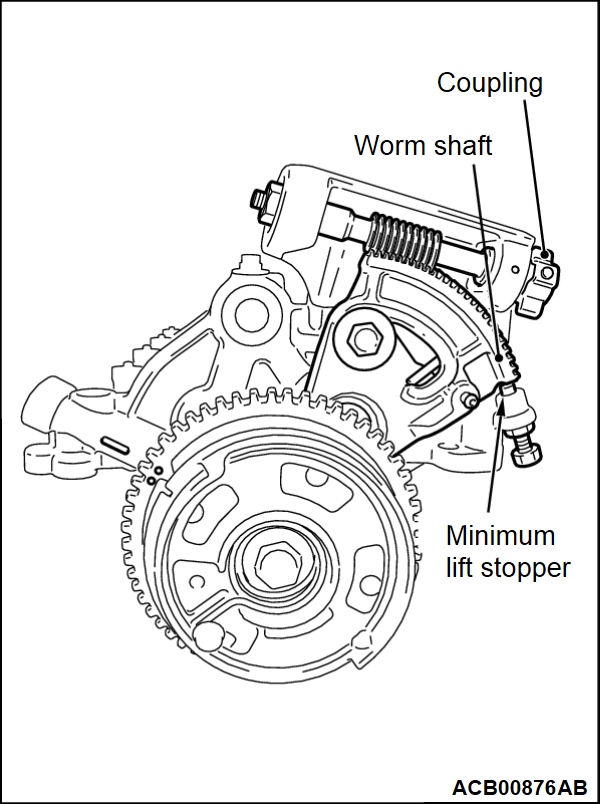

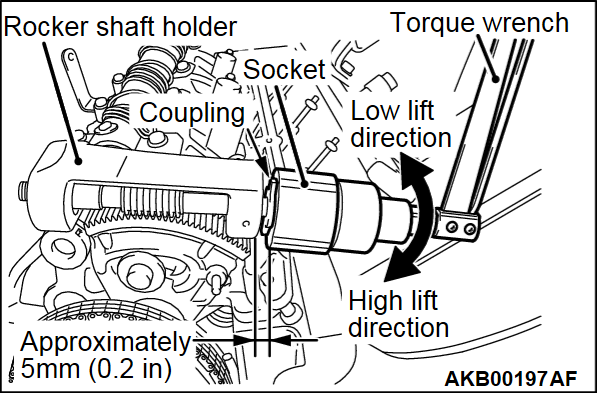

Slowly rotate the coupling clockwise. When lightly touching the worm wheel to the minimum lift stopper, stop the worm wheel at the position shown in the illustration.

| caution |

|

| note | When rotating the coupling clockwise, the worm wheel should move in the minimum lift direction. When rotating the coupling counterclockwise, the worm wheel should move in the maximum lift direction. |

| note | When manually rotating the coupling, insert a 12-point socket (24 mm) into the position on the coupling approximately 5 mm (0.2 inch) away from the rocker shaft holder. Connect the mini torque wrench and slowly rotate them. |

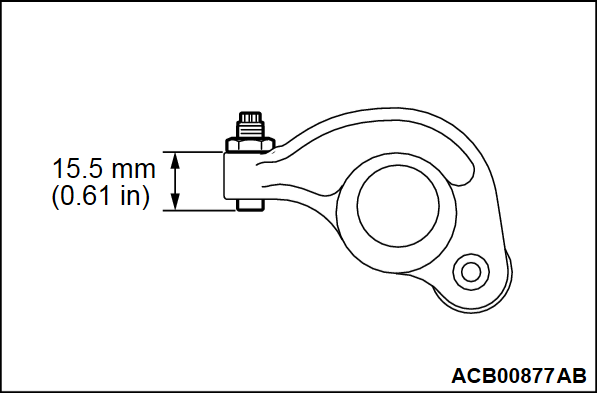

2. Adjust the rocker arm's adjusting screw at the exhaust side to be less than the dimension shown in the illustration.

3. Loosen and remove the bolts installing the rocker arm and camshaft assembly.

4. Lift the V.V.T. sprocket and the rocker arm and camshaft assembly and remove them from the cylinder head.

<<B>> NUT/ADJUSTING SCREW REMOVAL

| caution |

|

Remove the nuts and adjusting screws from the rocker arm.

INSTALLATION SERVICE POINTS

>>A<<DOWEL PIN INSTALLATION

Only when the dowel pin is pulled out from the camshaft for removing the V.V.T. sprocket, install the dowel pin, according to the following procedures.

1.

Set the dowel pin straightly to the installation hole of the camshaft.

| caution |

|

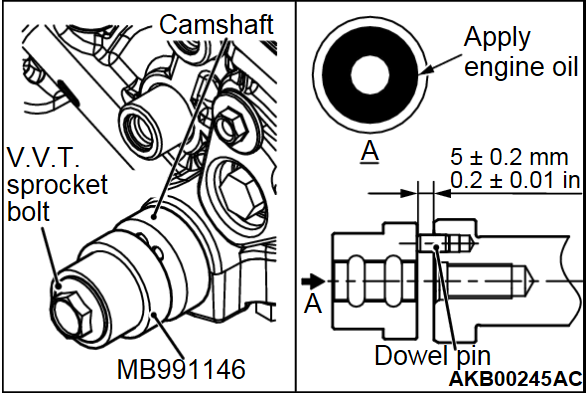

2. As shown in the illustration, apply an adequate and minimum amount of engine oil to the lower flange of the V.V.T. sprocket bolt and the threads of the V.V.T. sprocket bolt, also to the portion at the camshaft sprocket bolt side of the special tool installer (MB991146).

3. As shown in the illustration, set the special tool and the V.V.T. sprocket bolt.

4. Prevent the hexagonal portion of the camshaft rear end from rotating. Paying attention to the dowel pin not to be tilted, tighten the V.V.T. sprocket bolt and press-fit the dowel pin to 5 ± 0.2 mm (0.2 ± 0.01 inch).

>>B<< V.V.T. SPROCKET BOLT/ V.V.T. SPROCKET ASSEMBLY INSTALLATION

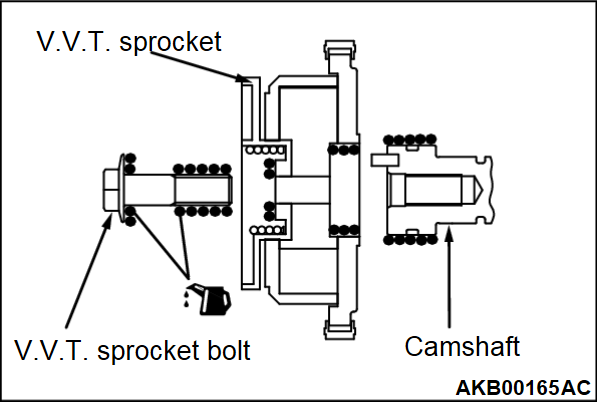

1. Assemble the V.V.T. sprocket assembly in the following procedure.

(1) Make sure that the dowel pin of the inlet camshaft assembly is positioned facing straight upward.

(2) Apply an adequate and minimum amount of engine oil to the lower flange of the V.V.T. sprocket bolt and the threads of the V.V.T. sprocket bolt, as well as to the outer circumference of the camshaft top end and all circumferences of the insertion portion of the V.V.T sprocket assembly.

(3) Slowly insert the inlet V.V.T. sprocket assembly into the normal position of the inlet camshaft assembly with its knock pin hole facing straight upward.

2. Install the V.V.T sprocket to the camshaft.

3. Securely insert the V.V.T sprocket into the furthest part.

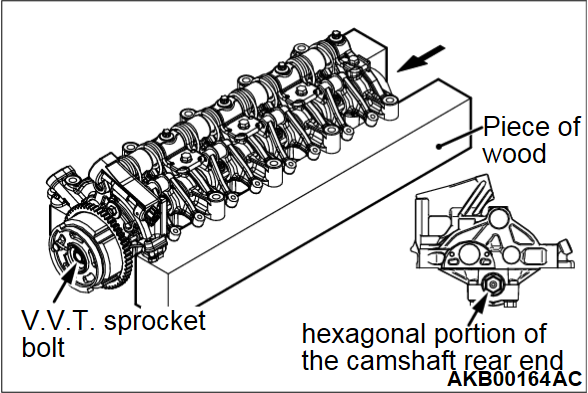

4. As shown in the illustration, mount the rocker arm and camshaft assembly on the piece of wood.

5. Holding the hexagonal portion of the camshaft rear end, check that the V.V.T sprocket assembly does not rotate.

6. Holding the hexagonal portion of the camshaft rear end, tighten the V.V.T sprocket bolt to the specified torque of 77 ± 6 N·m (57 ± 4 ft-lb).

>>C<< V.V.T. SPROCKET, ROCKER ARM AND CAMSHAFT ASSEMBLY INSTALLATION

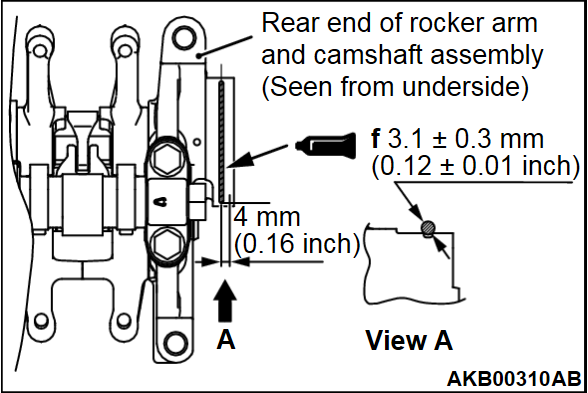

1. Adjust the rocker arm's adjusting screw at the exhaust side to be less than the dimension shown in the illustration.

2.

Slowly rotate the coupling clockwise. When lightly touching the worm wheel to the minimum lift stopper, stop the worm wheel at the position shown in the illustration.

| caution |

|

| note | When rotating the coupling clockwise, the worm wheel should move in the minimum lift direction. When rotating the coupling counterclockwise, the worm wheel should move in the maximum lift direction. |

| note | When manually rotating the coupling, insert a 12-point socket (24 mm) into the position on the coupling approximately 5 mm (0.2 inch) away from the rocker shaft holder. Connect the mini torque wrench and slowly rotate them. |

3. Align the overhaul and installation marks for the V.V.T. sprocket rocker arm and camshaft assembly with the mark of the rocker shaft holder.

4. Rotate the camshaft clockwise by approximately 15 degree so that the intake valve cannot be lifted.

5.

| caution |

|

Completely remove the liquid gasket adhered to the rocker arm and camshaft assembly and the cylinder head, and then degrease by white gasoline.

6.

Apply the bead of 3.1 ± 0.3 mm (0.12 ± 0.01 inch) liquid gasket to the position as shown in the illustration.

| caution | Install the V.V.T. sprocket, the rocker arm and camshaft assembly to the cylinder head within 3 minutes of applying the liquid gasket. |

Specified sealant:

- ThreeBond 1227D or equivalent

7.

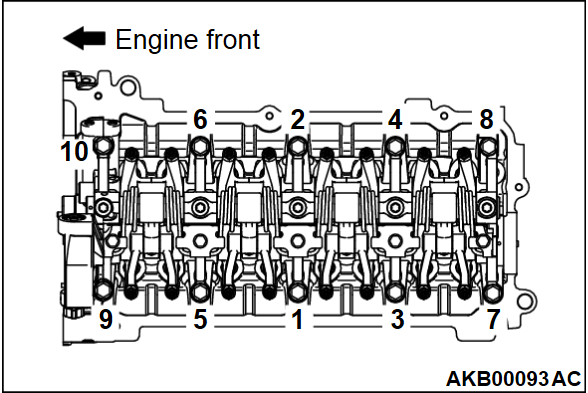

Tighten the rocker arm and camshaft assembly installation bolt in the sequence shown to temporary torque of 8.0 N·m (71 in-lb).

| caution | After installation, wipe off excessive sealant thoroughly from the sealant application area. |

8. Tighten the rocker arm and camshaft assembly installation bolt in the sequence shown to specified torque of 22 ± 3 N·m (16 ± 2 ft-lb).

>>D<< O-RING / OIL FEEDER CONTROL VALVE INSTALLATION

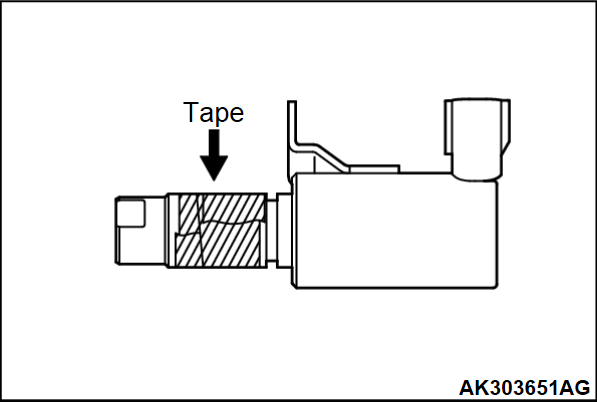

1.

Apply a small amount of engine oil to the O-ring of the oil feeder control valve.

| caution |

|

2. Install the oil feeder control valve on the cylinder head.

3. Tighten the oil feeder control valve to the specified torque of 10 ± 2 N·m (89 ± 17 in-lb).

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)