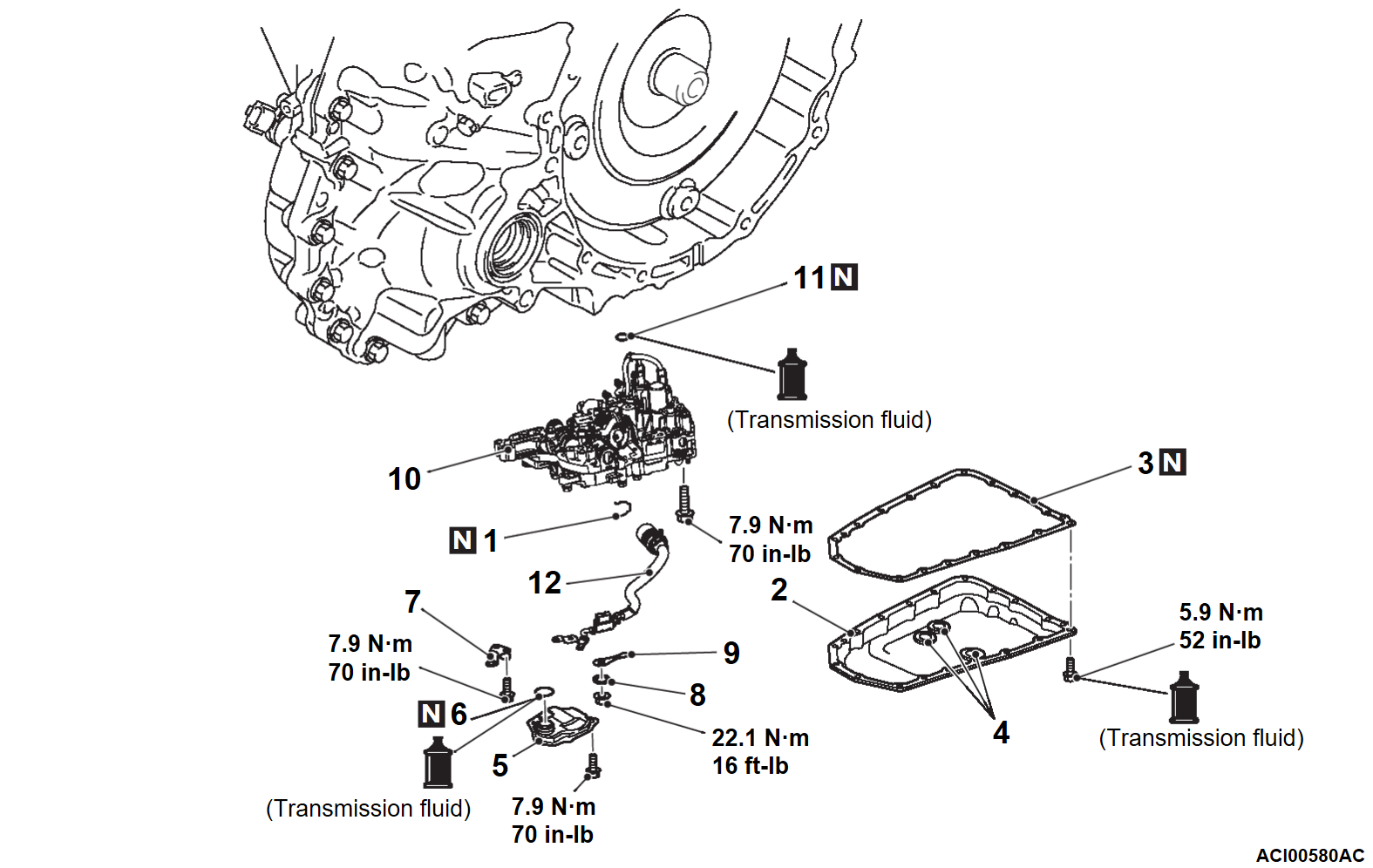

REMOVAL AND INSTALLATION

| caution |

Pre-removal operation | Post-installation operation |

REMOVAL SERVICE POINTS

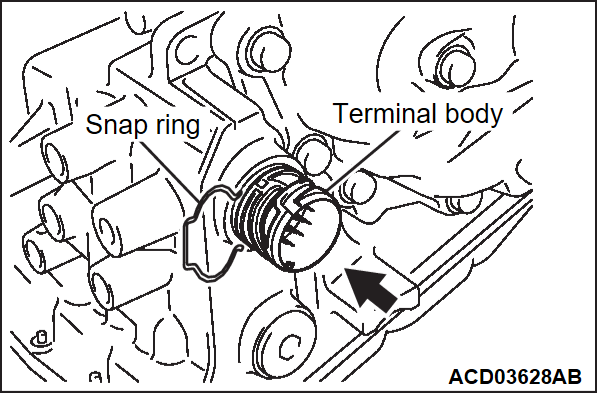

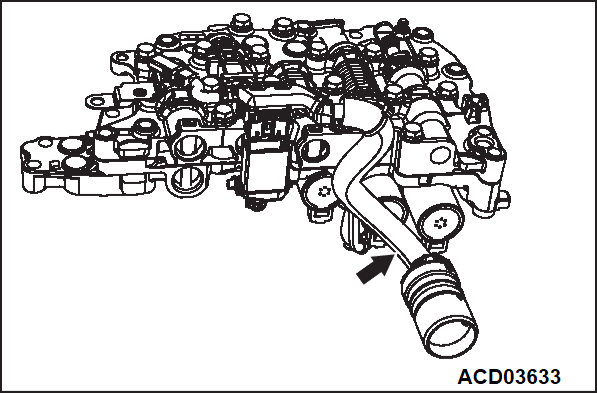

<<A>> SNAP RING REMOVAL

| caution | Be careful not to cause damage to the terminal body. |

Remove the snap ring from the terminal body, and press the terminal body into the transaxle case.

INSTALLATION SERVICE POINTS

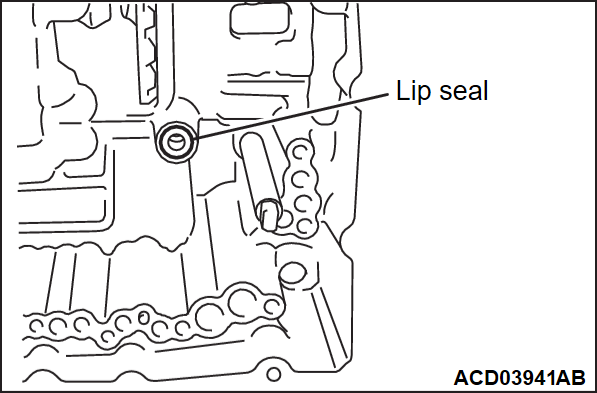

>>A<< LIP SEAL INSTALLATION

| caution |

|

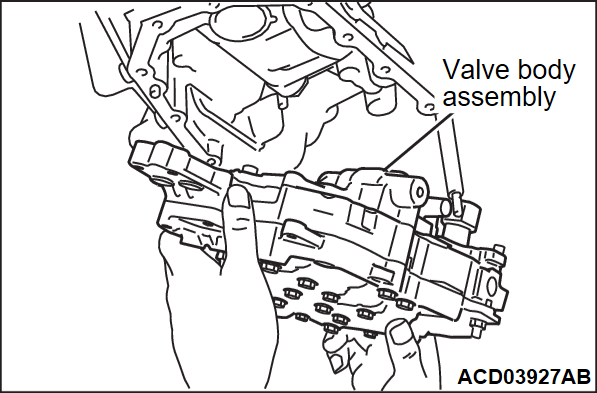

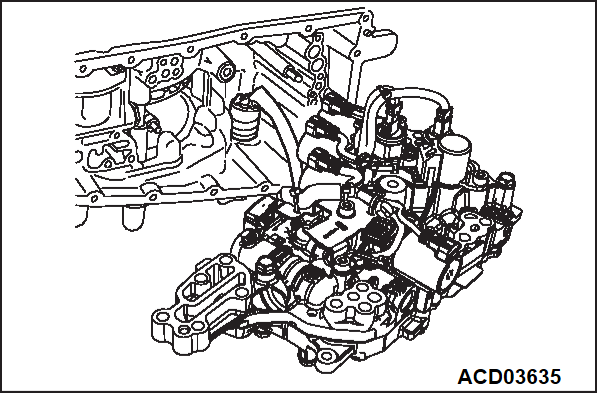

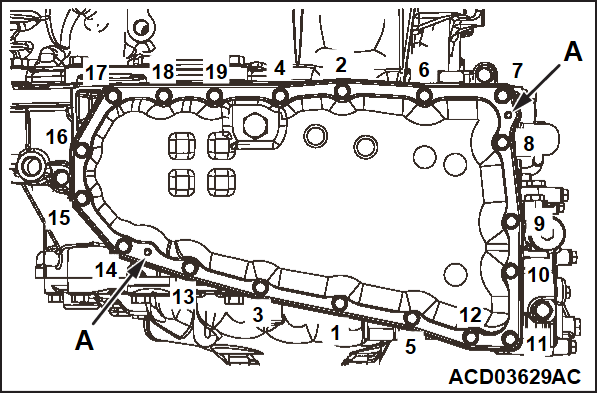

>>B<< VALVE BODY ASSEMBLY INSTALLATION

Install the control valve assembly on the transaxle case as follows.

1. Install the valve body harness on the control valve assembly.

2.

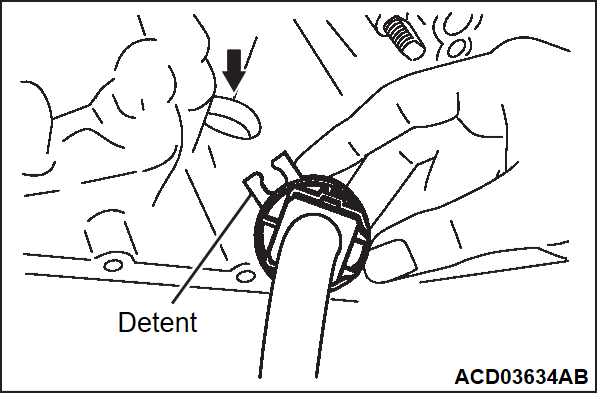

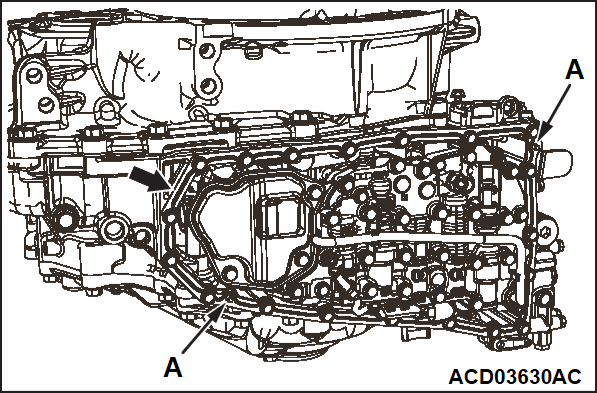

Install the terminal body on the transaxle case, while aligning the detent of terminal body with the transaxle case as shown in the diagram.

| caution |

|

3. Slide the control valve assembly from the left side, and install it on the transaxle case.

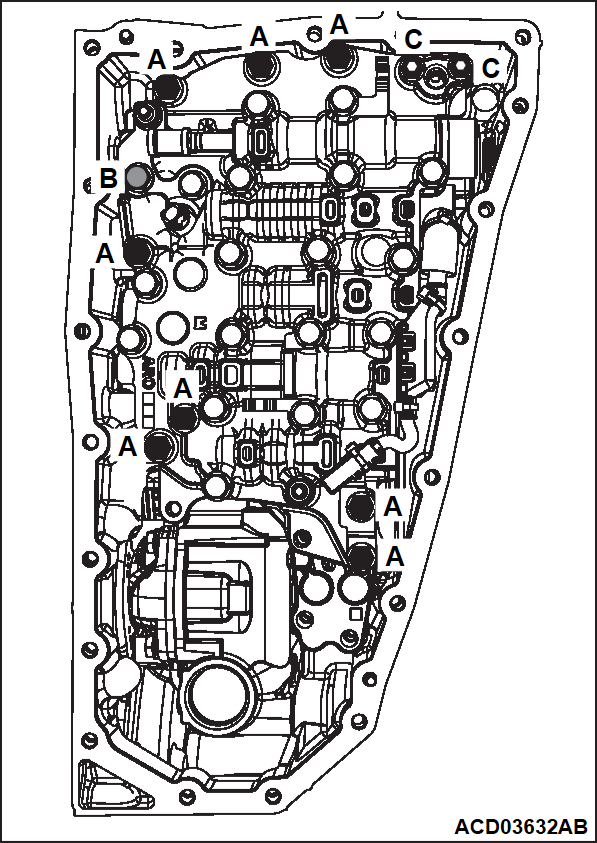

4. Install the fastening bolts of control valve assembly, and tighten to the specified torque of 7.9 N·m (70 in-lb).

|

| Bolt symbol | A | B | C |

| Shank length mm (inch) | 54 (2.1) | 44 (1.7) | 54 (2.1) |

| Quantity | 8 | 1 | 2 |

>>C<< OIL STRAINER INSTALLATION

Install the oil strainer, and tighten the fastening bolts to the specified torque of 7.9 N·m (70 in-lb).

>>D<< OIL PAN GASKET INSTALLATION

| caution |

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)