DTC U0146-00: Lost Communication with CGW

| caution |

|

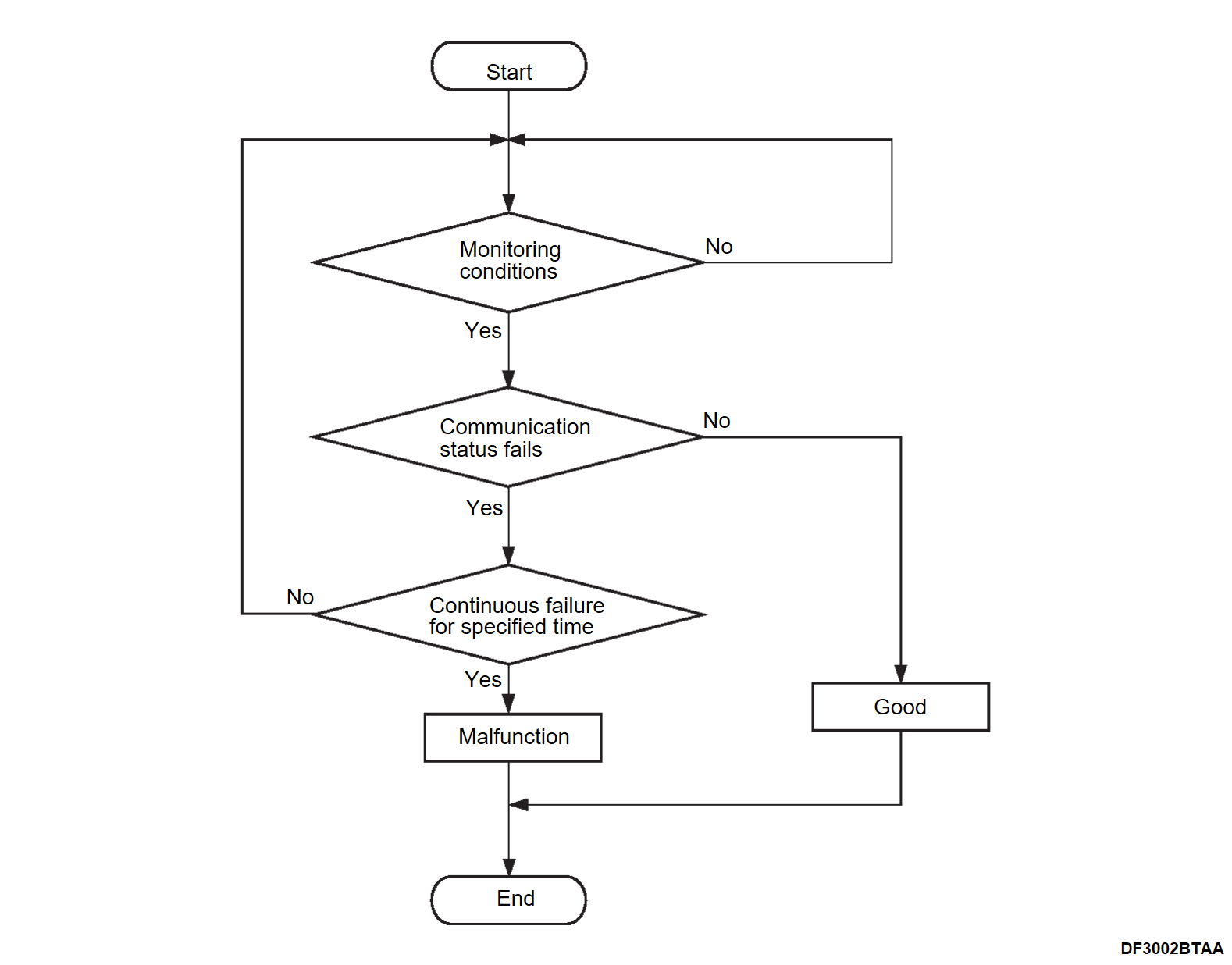

DESCRIPTIONS OF MONITOR METHODS

There is no data from 8CH CAN gateway for the specified time (8CH CAN gateway also detect communication error with ECM).

MONITOR EXECUTION

Continuous.

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- Power supply mode of electric motor switch is ON.

- 12V battery positive voltage is more than10.0 volts and is less than 16.5 volts.

Judgment Criterion

- Unable to receive 8CH CAN gateway signals through the CAN bus line for 4 seconds.

COMMENT

Current Trouble

- Some of the possible causes are a harness or connector damage between the ECM and the 8CH CAN gateway on the CAN bus line, or a failure in the ECM.

Past Trouble

- Proceed to troubleshoot based on a harness or connector damage on the CAN bus line between the ECM and 8CH CAN gateway, and a failure in the 8CH CAN gateway power supply system. For diagnostic procedure, refer to how to cope with past malfunctions (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Treat Past Trouble HOW TO TREAT PAST TROUBLE

).

).

| note | If a malfunction occurred in the past, a failure cannot be discovered through the scan tool (M.U.T.-III SE) CAN bus diagnosis even if there might be a problem with the CAN bus. In this case, refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ). Furthermore, it is possible to narrow down the areas of the possible failures from the DTCs that are set in the ECUs, which are communicating on the CAN bus (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN Fundamental – Basic Inspection – Diagnosis and Repair Workflow – Trouble Diagnosis Flow Chart Trouble Diagnosis Flow Chart ). Furthermore, it is possible to narrow down the areas of the possible failures from the DTCs that are set in the ECUs, which are communicating on the CAN bus (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN Fundamental – Basic Inspection – Diagnosis and Repair Workflow – Trouble Diagnosis Flow Chart Trouble Diagnosis Flow Chart ). ). |

FAIL-SAFE AND BACKUP FUNCTION

None.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 1 OBD- II DRIVE CYCLE .

.

.

.TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- CAN line harness damage or connector damage.

- 8CH CAN gateway failed.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

1.STEP 1. Using scan tool (M.U.T.-IIISE), diagnostic CAN bus line.

Use scan tool (M.U.T.-III SE) to perform CAN bus line diagnostic (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN Fundamental – Basic Inspection – Diagnosis and Repair Workflow – Trouble Diagnosis Flow Chart Trouble Diagnosis Flow Chart ).

). Repair CAN bus line (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN – DTC/Circuit Diagnosis – Malfunction Area Chart – Drivetrain CAN Communication Circuit Drivetrain CAN Communication Circuit

Repair CAN bus line (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN – DTC/Circuit Diagnosis – Malfunction Area Chart – Drivetrain CAN Communication Circuit Drivetrain CAN Communication Circuit ). Then

). Then

).

).Q: Is the CAN bus line normal?

Repair CAN bus line (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN – DTC/Circuit Diagnosis – Malfunction Area Chart – Drivetrain CAN Communication Circuit Drivetrain CAN Communication Circuit

Repair CAN bus line (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN – DTC/Circuit Diagnosis – Malfunction Area Chart – Drivetrain CAN Communication Circuit Drivetrain CAN Communication Circuit ). Then

). Then

2.STEP 2. Using scan tool (M.U.T.-III SE), read the other system DTC.

Use scan tool (M.U.T.-III SE) to check and see if a DTC is set in the 8CH CAN gateway. Perform troubleshooting of 8CH CAN gateway (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN Gateway – ECU Diagnosis Information – CAN Gateway – 8CH CAN gateway – DTC Index DTC Index

Perform troubleshooting of 8CH CAN gateway (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN Gateway – ECU Diagnosis Information – CAN Gateway – 8CH CAN gateway – DTC Index DTC Index ).

).

Q: Is any DTC set in the 8CH CAN gateway?

Perform troubleshooting of 8CH CAN gateway (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN Gateway – ECU Diagnosis Information – CAN Gateway – 8CH CAN gateway – DTC Index DTC Index

Perform troubleshooting of 8CH CAN gateway (Refer to ELECTRICAL & POWER CONTROL, LAN System – CAN Gateway – ECU Diagnosis Information – CAN Gateway – 8CH CAN gateway – DTC Index DTC Index ).

).3.STEP 3. Test the OBD-II drive cycle.

After erasing the DTC, carry out test drive with the drive cycle pattern, and recheck the DTC. Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ). Then

). Then

Intermittent malfunction in CAN bus line between ECM and BMU (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction in CAN bus line between ECM and BMU (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).

(1) Use scan tool (M.U.T.-III SE) to erase the DTC.

(2) Carry out test drive with the drive cycle pattern (Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 1 OBD- II DRIVE CYCLE ).

).

).

).(3) Use scan tool (M.U.T.-III SE) to recheck the DTC.

Q: Is DTC U0146-00 set?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ). Then

). Then

Intermittent malfunction in CAN bus line between ECM and BMU (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction in CAN bus line between ECM and BMU (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).4.STEP 4. Test the OBD-II drive cycle.

After erasing the DTC, carry out test drive with the drive cycle pattern, and recheck the DTC. The inspection is complete.

The inspection is complete.

(1) Use scan tool (M.U.T.-III SE) to erase the DTC.

(2) Carry out test drive with the drive cycle pattern (Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 1 OBD- II DRIVE CYCLE ).

).

).

).(3) Use scan tool (M.U.T.-III SE) to recheck the DTC.

Q: Is DTC U0146-00 set?

The inspection is complete.

The inspection is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)