DTC P0459-00: Purge control solenoid valve circuit high input

CIRCUIT OPERATION

- MFI relay is built into the IPDM E/R.

- Power is supplied to the evaporative emission purge solenoid connector terminal number 2 from the MFI relay connector terminal.

- The ECM connector terminal number 14 makes the power transistor in the unit be in ON position, and that makes currents go on the evaporative emission purge solenoid connector terminal number 1.

TECHNICAL DESCRIPTION

In response to a signal from the ECM, the evaporative emission purge solenoid controls the flow rate of the purge air to be introduced into the intake manifold.

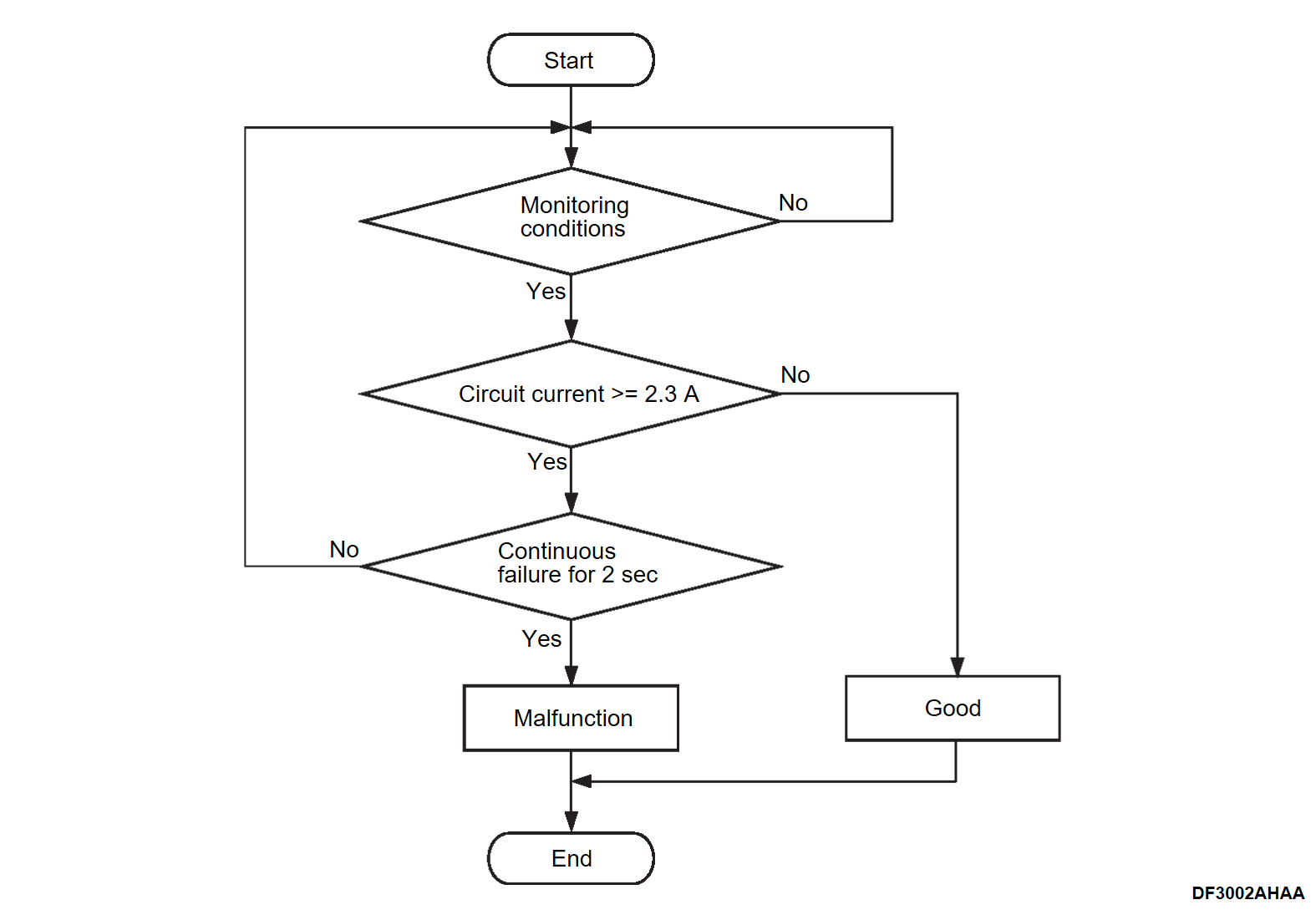

DESCRIPTIONS OF MONITOR METHODS

The ECM detects short malfunction.

MONITOR EXECUTION

Continuous.

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- More than 2 seconds have passed since the power supply mode of electric motor switch was ON.

- Evaporative emission purge solenoid is ON.

- 12V battery positive voltage is between 10.0 and 16.5 volts.or

- More than 2 seconds have passed since the key-off evaporative leakage monitoring was started.

- Evaporative emission purge solenoid is ON.

- 12V battery positive voltage is between 10.0 and 16.5 volts.

Judgment Criterion

- The coil current is 2.3 amperes or more with the evaporative emission purge solenoid driving for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

Prohibit introduction of purges.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 1 OBD- II DRIVE CYCLE .

.

.

.TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Evaporative emission purge solenoid failed.

- Shorted evaporative emission purge solenoid circuit, harness damage or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

1.STEP 1. Using scan tool (M.U.T.-IIISE), perform the actuator test.

Use scan tool (M.U.T.-III SE) to perform the actuator test (Refer to ACTUATOR TEST REFERENCE TABLE ).

).

).

).- Item number 30: Purge Control Solenoid Valve

OK: Operating sound can be heard and the valve vibrates

Q: Is the check result normal?

2.STEP 2. Check harness between evaporative emission purge solenoid connector terminal number 1 and ECM connector terminal number 14.

Check output line for short circuit. Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.

Q: Is the check result normal?

Repair or replace the connector, or repair the damaged harness wire.

Repair or replace the connector, or repair the damaged harness wire.3.STEP 3. Using scan tool (M.U.T.-IIISE), perform the actuator test.

Use scan tool (M.U.T.-III SE) to perform the actuator test (Refer to ACTUATOR TEST REFERENCE TABLE ).

). Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

).

).

).- Item number 30: Purge Control Solenoid Valve

OK: Operating sound can be heard and the valve vibrates

Q: Is the check result normal?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

).4.STEP 4. Test the OBD-II drive cycle.

After erasing the DTC, carry out test drive with the drive cycle pattern, and recheck the DTC. Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).

(1) Use scan tool (M.U.T.-III SE) to erase the DTC.

(2) Carry out test drive with the drive cycle pattern (Refer to Diagnostic Function, OBD-II Drive Cycle – Pattern 1 OBD- II DRIVE CYCLE ).

).

).

).(3) Use scan tool (M.U.T.-III SE) to recheck the DTC.

Q: Is DTC P0459-00 set?

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION

Replace the ECM (Refer to ENGINE CONTROL MODULE (ECM) REMOVAL AND INSTALLATION ).

). Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Intermittent malfunction (Refer to GENERAL INFORMATION, General Information – How to Use Troubleshooting/Inspection Service Points – How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)