Work Procedure

- Always adjust the camera aiming after removing and installing or replacing the front camera unit.

- Always adjust the camera aiming after removing and installing or replacing the windshield glass.

| caution |

|

Preparation

1.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis of front camera unit. Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to DTC IndexDTC Index

Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to DTC IndexDTC Index  .

.

Is any DTC detected?

Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to DTC IndexDTC Index

Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to DTC IndexDTC Index  .

.2.PREPARATION BEFORE CAMERA AIMING ADJUSTMENT

- Perform pre-inspection for diagnosis.

- Adjust the tire pressure to the specified pressure value.

- Maintain no-load in vehicle.

- Check if coolant and engine oil are filled up to correct level and fuel tank is full.

- Shift the selector lever to "P" position and release the parking brake.

- Clean the windshield.

- Completely clear off the instrument panel.

note If any fixed object is put on instrument panel, cover the upper of the instrument panel with black cloth to prevent an object from reflecting in the windshield.

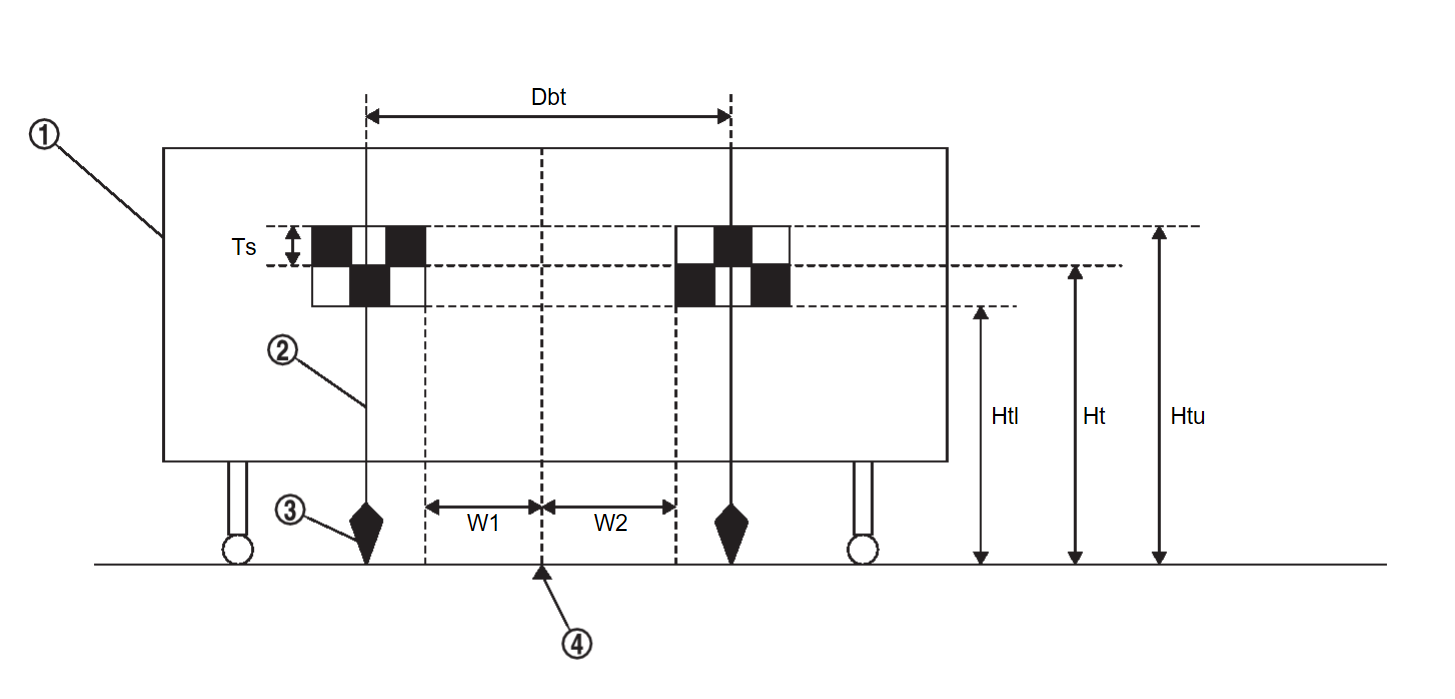

3. PREPARATION OF J-52266-2 ALIGNMENT TARGET

Prepare the alignment target according to the following procedure and the figure.

- Attach the J-52266-2 alignment target to a movable board.

note - Use the board that peripheral area of the target is monochrome such as a whiteboard.

- Notice that the cross of the target is horizontal and vertical.

Side of a target (Ts) : 120 mm (4.72 in) Height of a target lower end (Htl) : 1,180 mm (46.46 in) Height of a target center (Ht) : 1,300 mm (51.18 in) Height of a target upper end (Htu) : 1,420 mm (55.91 in) Width between a right target center from a left target center (Dbt) : 720 mm (28.35 in) W1 : 180 mm (7.09 in) W2 : 180 mm (7.09 in)

Target Setting

| caution |

|

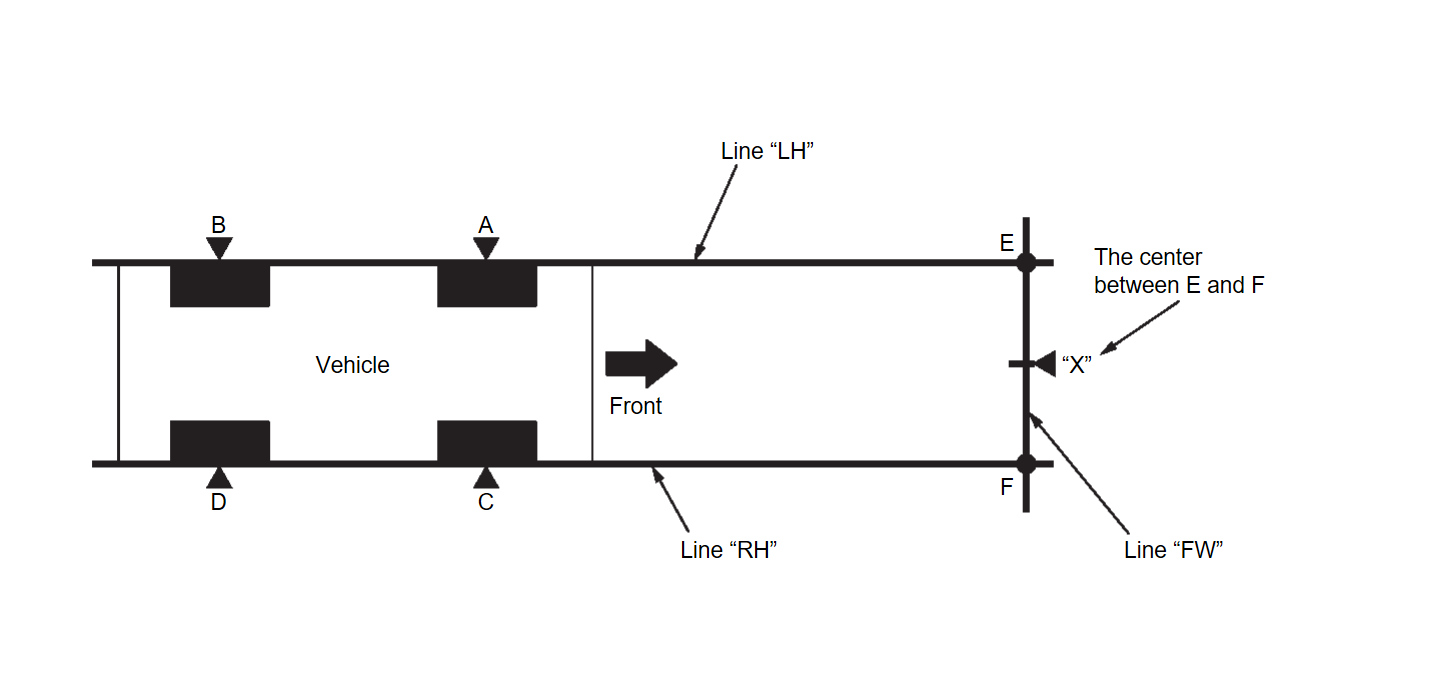

1.TARGET SETTING

| A – E (C – F) | : 3,000 mm (118.11 in) |

- Mark points "A", "B", "C" and "D" at the center of the lateral surface of each wheels.

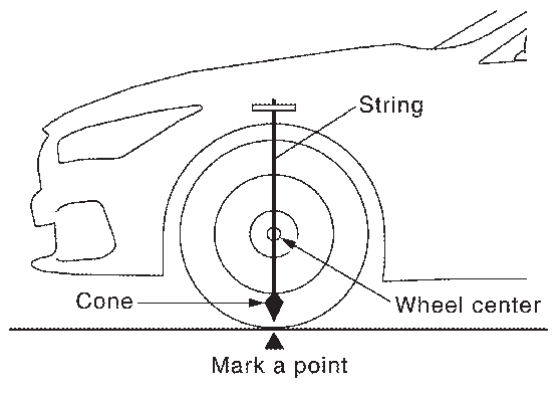

note Hang a string with a cone from the fender so as to pass through the center of wheel, and then mark a point at the center of the lateral surface of the wheel. - Draw line "LH" passing through points "A" and "B" on the left side of vehicle.

note Approximately 4 m (13.12 ft) or more from the front end of vehicle. - Mark point "E" on the line "LH" at the positions 3,000 mm (118.11 in) from point "A".

- Draw line "RH" passing through points "C" and "D" on the right side of vehicle in the same way as step 2.

note Approximately 4 m (13.12 ft) or more from the front end of vehicle. - Mark point "F" on the line "RH" at the positions 3,000 mm (118.11 in) from point "C".

- Draw line "FW" passing through the points "E" and "F" on the front side of vehicle.

- Mark point "X" at the center of point "E" and "F" on the line "FW".

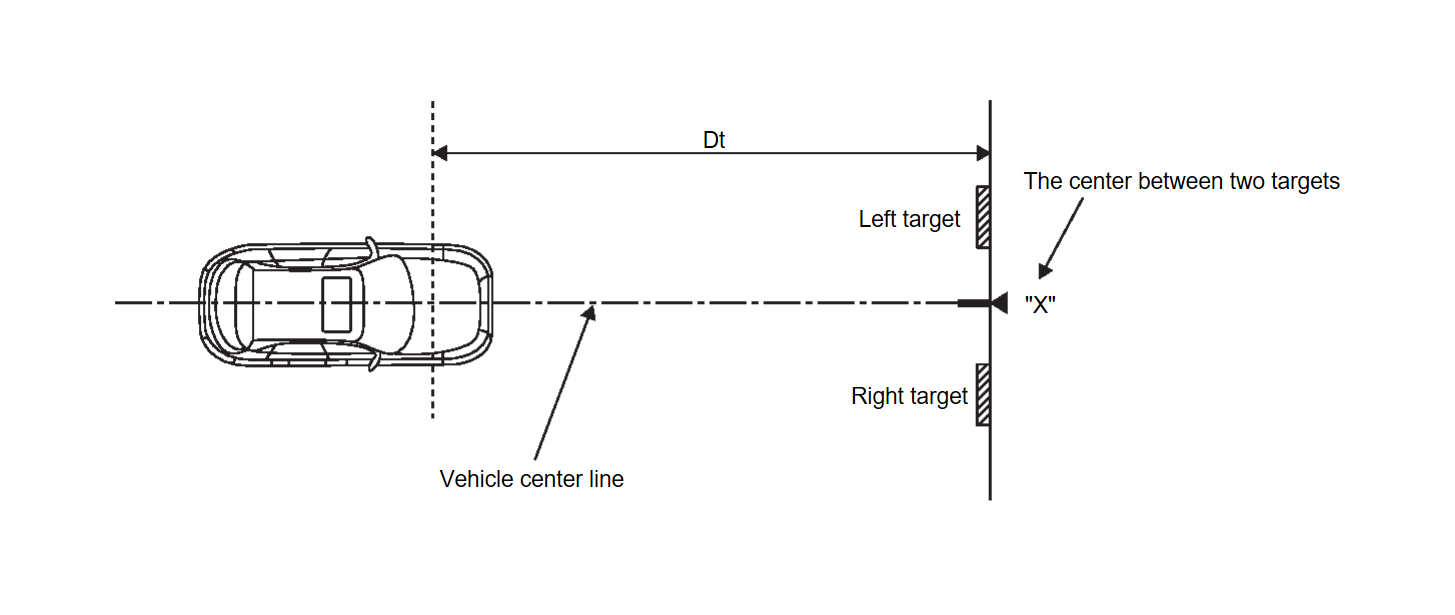

caution Make sure that "E" to "X" is equal to "F" to "X". - Center the J-52266-2 alignment target at point "X" facing the vehicle.

Dt : 3,000 mm (118.11 in)

Camera Aiming Adjustment

| caution | Perform the adjustment under unloaded vehicle condition. |

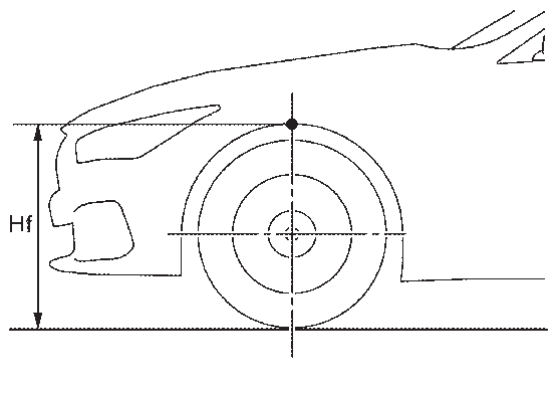

1.CHECK VEHICLE HEIGHT

Measure the wheelarch height.

| Hfl: Front left wheelarch height [mm] | |

| Hfr: Front right wheelarch height [mm] | |

Dh(mm) = (Hfl+Hfr) ÷ 2 - 809 <Vehicles with 18 inch tire>

Dh(mm) = (Hfl+Hfr) ÷ 2 - 813 <Vehicles with 20 inch tire>

| caution | Be sure to measure wheelarch height correctly. |

| note | The value of Dh may become negative. |

2.CAMERA AIMING ADJUSTMENT

With M.U.T.-III SE

With M.U.T.-III SE| caution | Operate M.U.T.-III SE outside the vehicle, and close all the doors. (To retain vehicle attitude appropriately) |

- Select "Special Function" on "LANE CAMERA" with M.U.T.-III SE.

- Select "AUTO AIM".

- Confirm the following items;

- The target should be accurately placed.

- The vehicle should be stopped.

- Select "OK" to perform camera aiming.

caution - Never select "OK" when the J-52266-2 alignment target is not accurately placed.

- Wait 5 seconds or more after selecting "OK".

- Input the following parameters, and then select "OK".

Dh : Calculated value in 1. CHECK VEHICLE HEIGHT VP : 0 Dt : 3,000 mm Dbt : 720 mm Htu : 1,420 mm Htl : 1,180 mm Ts : 120 mm note - The M.U.T.-III SE only accepts the value which is input in 2 mm increments.

- When the value of Dh is an odd number, add or subtract 1 to make it even and input the value.Example: When the value is -21 mm, input -20 mm or -22 mm (Whichever is input, it does not affect the aiming).

- Confirm the displayed item.

- "Normally Completed": Select "OK".

- "SUSPENSION", "Abnormally completed": Perform the following services.

Displayed item Possible cause Service procedure SUSPENSION - Temporary malfunction in internal processing of the front camera unit.

- Front camera unit malfunction.

Position the target appropriately again. Then perform the aiming again.Abnormally completed 2 Front camera unit cannot detect the target - A target is not-yet-placed.

- The position of the targets is not correct.

- The position of the front camera unit is not correct.

- Inappropriate work environment.

- Inappropriate vehicle condition.

- Input value is not correct against actual setting position.

Position the target appropriately again. Then perform the aiming again.3 Roll angle is outside the threshold - The position of the targets is not correct.

- The position of the front camera unit is not correct.

- Inappropriate work environment.

- Inappropriate vehicle condition.

- Input value is not correct against actual setting position.

4 Yaw/pitch angle is outside the threshold. - The position of the targets is not correct.

- The position of the front camera unit is not correct.

- Inappropriate work environment.

- Inappropriate vehicle condition.

- Input value is not correct against actual setting position.

5 Input value of aiming is invalid. - Input value is not correct against actual setting position.

Correct input value of aiming and perform camera aiming again. 6 The size of target is different. (A numerical value input to M.U.T.-III SE differs from detected size) - The position of the targets is not correct.

- The position of the front camera unit is not correct.

- Inappropriate work environment.

- Inappropriate vehicle condition.

- Input value is not correct against actual setting position.

Position the target appropriately again. Then perform the aiming again.7 The size of target is different. (A numerical value input to M.U.T.-III SE differs from detected size) - The position of the targets is not correct.

- The position of the front camera unit is not correct.

- Inappropriate work environment.

- Inappropriate vehicle condition.

- Input value is not correct against actual setting position.

8 Yaw/pitch angle is outside the threshold. - The position of the targets is not correct.

- The position of the front camera unit is not correct.

- Inappropriate work environment.

- Inappropriate vehicle condition.

- Input value is not correct against actual setting position.

9 Yaw/pitch angle is outside the threshold. - The position of the targets is not correct.

- The position of the front camera unit is not correct.

- Inappropriate work environment.

- Inappropriate vehicle condition.

- Input value is not correct against actual setting position.

10 Detect several targets. - The position of the targets is not correct.

- The position of the front camera unit is not correct.

- Inappropriate work environment.

- Inappropriate vehicle condition.

- Input value is not correct against actual setting position.

11 Internal process malfunction - Then turn the ignition switch OFF → ON. Accurately set target and perform camera aiming again.

- If ABNORMALLY COMPLETED again after aiming, replace front camera unit.

12 Internal process time out - Then turn the ignition switch OFF → ON. Accurately set target and perform camera aiming again.

- If ABNORMALLY COMPLETED again after aiming, replace front camera unit.

note Replace front camera unit if "SUSPENSION" are repeatedly indicated.

- Confirm that "Normally completed" is displayed and then select "Home"/"Return one level" to close the adjustment procedure.

3.PERFORM SELF-DIAGNOSIS

With M.U.T.-III SE

With M.U.T.-III SEPerform self-diagnosis of "LANE CAMERA" with M.U.T.-III SE.

Is any DTC detected?

Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to DTC IndexDTC Index

Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to DTC IndexDTC Index  .

.4.ACTION TEST

Perform the following system operation by action test.

- LDW: Refer to Work ProcedureInspection Procedure

.

. - LDP: Refer to Work ProcedureInspection Procedure

.

. - Active Blind Spot Assist [ABSA]: Refer to Work Procedure

.

. - TSR: Refer to Work Procedure

.

.

: WORK END

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)