DTC Diagnosis Procedure

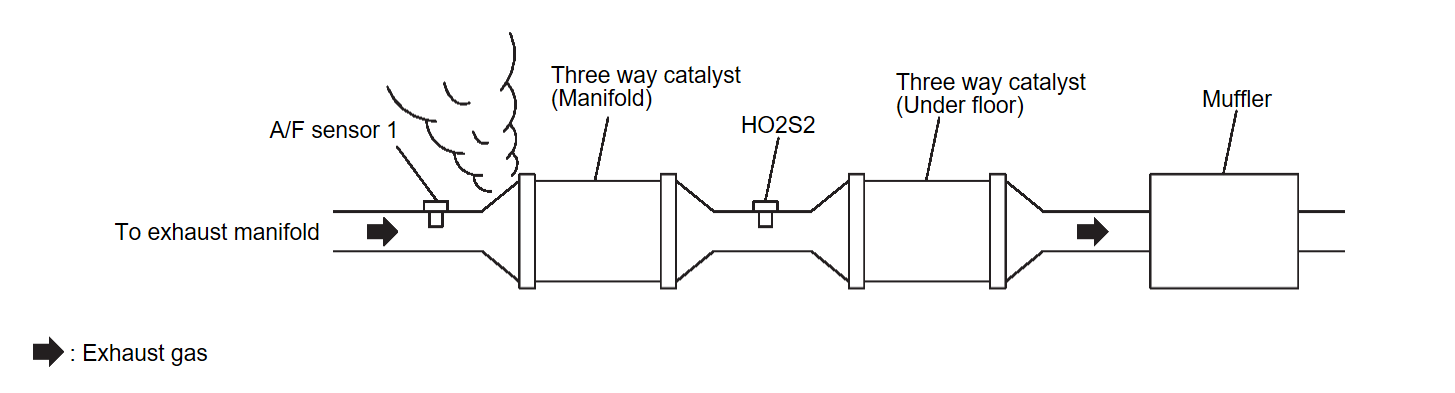

1.CHECK EXHAUST GAS LEAK

- Start engine and run it at idle.

- Listen for an exhaust gas leak before three way catalyst (manifold).

Is exhaust gas leak detected?

Repair or replace error-detected parts.

Repair or replace error-detected parts.2.CHECK FOR INTAKE AIR LEAK

- Listen for an intake air leak after the mass air flow sensor.

- Check PCV hose connection.

Intake air leak detected?

Repair or replace error-detected parts.

Repair or replace error-detected parts.3.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect corresponding A/F sensor 1 harness connector.

- Disconnect ECM harness connector.

- Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

+ − Continuity A/F sensor 1 ECM Connector Terminal Connector Terminal F18 1 F51 56 Existed 2 60 - Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector and ground.

+ − Continuity A/F sensor 1 Connector Terminal F18 1 Ground Not existed 2 + − Continuity ECM Connector Terminal F51 56 Ground Not existed 60 - Also check harness for short to power.

Is the inspection result normal?

Repair or replace error-detected parts.

Repair or replace error-detected parts.4..CHECK A/F SENSOR 1 FUNCTION CHECK-1

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 at idle.

5.CHECK A/F SENSOR 1 FUNCTION-2

- Clear the mixture ratio self-learning value. Refer to DescriptionDescription

.

. - Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for 1 minute under no load.

- Let engine idle for 1 minute.

- Keep engine speed between 2,500 and 3,000 rpm for 20 minutes.

- Check DTC.

Is DTC detected?

Refer to Removal and Installation

Refer to Removal and Installation .

.6.CHECK FUEL PRESSURE

7. DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging. Refer to Exploded View .

. Replace “fuel filter and fuel pump assembly”. Refer to Exploded View

Replace “fuel filter and fuel pump assembly”. Refer to Exploded View .

. Repair or replace error-detected parts.

Repair or replace error-detected parts.

.

.Is the inspection result normal?

Replace “fuel filter and fuel pump assembly”. Refer to Exploded View

Replace “fuel filter and fuel pump assembly”. Refer to Exploded View .

. Repair or replace error-detected parts.

Repair or replace error-detected parts.8.CHECK MASS AIR FLOW SENSOR

With M.U.T.-III SE

With M.U.T.-III SE- Install all removed parts.

- Check “MASS AIR FLOW SENSOR (g/s)” in “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- For specification, refer to Component Inspection

.

.

With GST

With GST- Install all removed parts.

- Check mass air flow sensor signal in Service $01 with GST.

- For specification, refer to MASS AIR FLOW SENSOR : Service Data

.

.

Is the measurement value within the specification?

Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or grounds. Refer to DTC Description

Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or grounds. Refer to DTC Description .

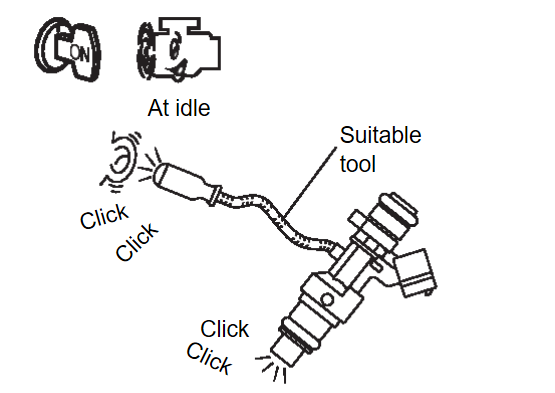

.9.CHECK FUNCTION OF FUEL INJECTOR

With M.U.T.-III SE

With M.U.T.-III SE- Start engine.

- Perform "POWER BALANCE" in "Actuator Test" (in "Special Function") mode of "ENGINE" using M.U.T.-III SE.

- Make sure that each circuit produces a momentary engine speed drop.

Is the inspection result normal?

INSPECTION END

INSPECTION END Perform trouble diagnosis for “FUEL INJECTOR”, refer to Component Function Check

Perform trouble diagnosis for “FUEL INJECTOR”, refer to Component Function Check .

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

Without M.U.T.-III SE

Without M.U.T.-III SE