DTC Diagnosis Procedure

1.CHECK THE CAPLESS FLAP

Check flap of capless unit for easy opening and closing operation, when bar or nozzle with Φ20 - 21 mm (0.79 - 0.83 in) is inserted or nozzle. Replace the fuel filler tube.

Replace the fuel filler tube.

Is the inspection result normal?

Replace the fuel filler tube.

Replace the fuel filler tube.2.CHECK THE FILLER TUBE

While applying air of 1 kPa (0.01 kg/cm2, 0.145 psi) to filler tube, check air for leakage. Replace the fuel filler tube CONDITION.

Replace the fuel filler tube CONDITION.

Is the inspection result normal?

Replace the fuel filler tube CONDITION.

Replace the fuel filler tube CONDITION.3.CHECK FOR EVAP LEAK

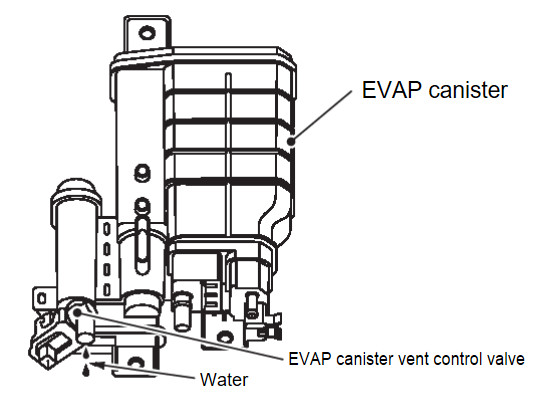

4.CHECK EVAP CANISTER VENT CONTROL VALVE

Check the following. Repair or replace EVAP canister vent control valve and O-ring. Refer to Removal and Installation

Repair or replace EVAP canister vent control valve and O-ring. Refer to Removal and Installation .

.

- EVAP canister vent control valve is installed properly.Refer to Removal and Installation

.

. - EVAP canister vent control valve.Refer to Removal and Installation

.

.

Is the inspection result normal?

Repair or replace EVAP canister vent control valve and O-ring. Refer to Removal and Installation

Repair or replace EVAP canister vent control valve and O-ring. Refer to Removal and Installation .

.5.CHECK IF EVAP CANISTER SATURATED WITH WATER

- Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

- Check if water will drain from the EVAP canister.

Does water drain from EVAP canister?

-1With M.U.T.-III SE:

-1With M.U.T.-III SE:  .

. -2Without M.U.T.-III SE:

-2Without M.U.T.-III SE:  .

.6.CHECK EVAP CANISTER

Weigh the EVAP canister assembly with the EVAP canister vent control valve and EVAP control system pressure sensor attached. Refer to Removal and Installation .

. -1With M.U.T.-III SE:

-1With M.U.T.-III SE:  .

. -2Without M.U.T.-III SE:

-2Without M.U.T.-III SE:  .

.

.

.The weight should be less than 2.3 kg (5.1 lb).

Is the inspection result normal?

-1With M.U.T.-III SE:

-1With M.U.T.-III SE:  .

. -2Without M.U.T.-III SE:

-2Without M.U.T.-III SE:  .

.7.DETECT MALFUNCTIONING PART

Check the following.

- EVAP canister for damage

- EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

: Repair hose or replace EVAP canister. Refer to Removal and Installation .

.

.

.8.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With M.U.T.-III SE

With M.U.T.-III SE- Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

- Start the engine and let it idle.

- Select "PURG VOL CONT/V" in "Actuator Test" (in "Special Function") mode of "ENGINE" using M.U.T.-III SE.

- Adjust "PURG VOL CONT/V" opening to 100%.

- Check vacuum hose for vacuum.

Vacuum should exist.

Is the inspection result normal?

9.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without M.U.T.-III SE

Without M.U.T.-III SE- Start the engine and warm it up to normal operating temperature.

- Stop the engine.

- Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

- Start the engine and let it idle for at least 80 seconds.

- Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

Vacuum should exist.

Is the inspection result normal?

10.CHECK VACUUM HOSE

Check vacuum hoses for clogging or disconnection. Repair or reconnect the hose.

Repair or reconnect the hose.

Is the inspection result normal?

Repair or reconnect the hose.

Repair or reconnect the hose.11.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Check the EVAP canister purge volume control solenoid valve. Refer to Component Inspection .

. Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location

Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location .

.

.

.Is the inspection result normal?

Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location

Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location .

.12.CHECK FUEL TANK TEMPERATURE SENSOR

Check the fuel tank temperature sensor. Refer to Component Inspection .

. Replace fuel level sensor unit. Refer to Exploded View

Replace fuel level sensor unit. Refer to Exploded View .

.

.

.Is the inspection result normal?

Replace fuel level sensor unit. Refer to Exploded View

Replace fuel level sensor unit. Refer to Exploded View .

.13.CHECK EVAP PURGE LINE

Check EVAP purge line (pipe, rubber tube, fuel tank and EVAP canister) for cracks or improper connection. Repair or reconnect the hose.

Repair or reconnect the hose.

Refer to System Description .

.

.

.Is the inspection result normal?

Repair or reconnect the hose.

Repair or reconnect the hose.15.CHECK EVAP/ORVR LINE

Check EVAP/ORVR line between EVAP canister and fuel tank for clogging, kink, looseness and improper connection. For location, Refer to System Description .

. Repair or replace hoses and tubes.

Repair or replace hoses and tubes.

.

.Is the inspection result normal?

Repair or replace hoses and tubes.

Repair or replace hoses and tubes.16.CHECK RECIRCULATION LINE

Check recirculation line between fuel filler tube and fuel tank for clogging, kink, cracks, looseness and improper connection. Repair or replace hose, tube or fuel filler tube. Refer to Exploded View

Repair or replace hose, tube or fuel filler tube. Refer to Exploded View .

.

Is the inspection result normal?

Repair or replace hose, tube or fuel filler tube. Refer to Exploded View

Repair or replace hose, tube or fuel filler tube. Refer to Exploded View .

.17.CHECK REFUELING EVAP VAPOR CUT VALVE

Check the refueling EVAP vapor cut valve. Refer to Component Inspection .

. Replace refueling EVAP vapor cut valve with fuel tank. Refer to Removal & InstallationRemoval and Installation

Replace refueling EVAP vapor cut valve with fuel tank. Refer to Removal & InstallationRemoval and Installation .

.

.

.Is the inspection result normal?

Replace refueling EVAP vapor cut valve with fuel tank. Refer to Removal & InstallationRemoval and Installation

Replace refueling EVAP vapor cut valve with fuel tank. Refer to Removal & InstallationRemoval and Installation .

.18.CHECK FUEL LEVEL SENSOR

Check the fuel level sensor. Refer to Component Function Check (FULL TFT METER) or Component Function Check

(FULL TFT METER) or Component Function Check (7 INCH INFORMATION DISPLAY).

(7 INCH INFORMATION DISPLAY). Replace EVAP control system pressure sensor. Refer to Removal and Installation

Replace EVAP control system pressure sensor. Refer to Removal and Installation .

. Replace fuel level sensor unit. Refer to Exploded View

Replace fuel level sensor unit. Refer to Exploded View .

.

(FULL TFT METER) or Component Function Check

(FULL TFT METER) or Component Function Check (7 INCH INFORMATION DISPLAY).

(7 INCH INFORMATION DISPLAY).Is the inspection result normal?

Replace EVAP control system pressure sensor. Refer to Removal and Installation

Replace EVAP control system pressure sensor. Refer to Removal and Installation .

. Replace fuel level sensor unit. Refer to Exploded View

Replace fuel level sensor unit. Refer to Exploded View .

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)