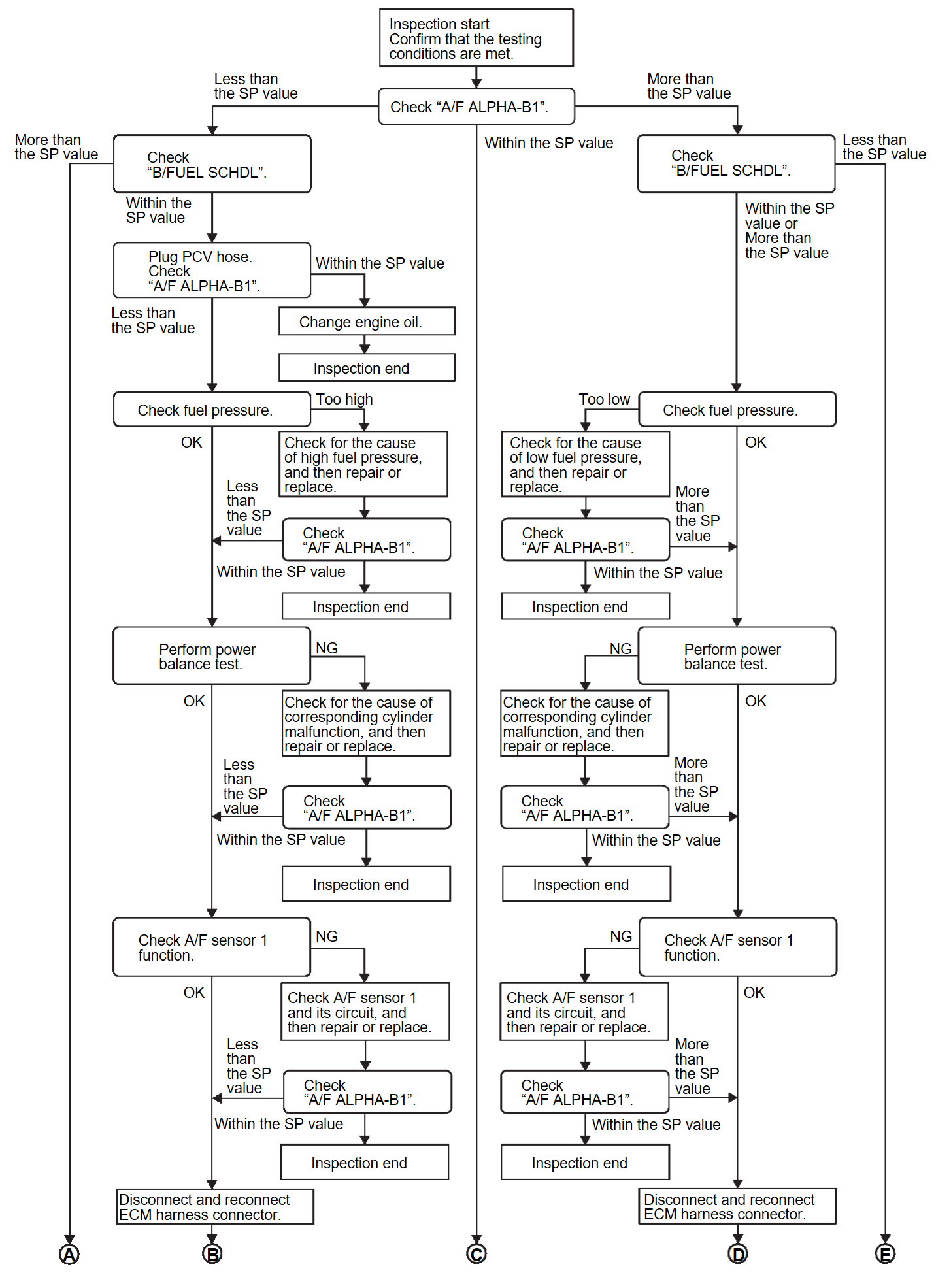

DTC Diagnosis Procedure

OVERALL SEQUENCE

| note | The SP value can be confirmed in Data List items whose name ends with "SP MIN" and "SP MAX" |

| note | The SP value can be confirmed in Data List items whose name ends with "SP MIN" and "SP MAX" |

DETAILED PROCEDURE

1.CHECK “A/F ALPHA-B1”

With M.U.T.-III SE

With M.U.T.-III SE- Start engine.

- Confirm that the testing conditions are met. Refer to Component Function Check

.

. - Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “A/F ALPHA-B1”.

Is the measurement value within the SP value?

-1Less than the SP value:

-1Less than the SP value:  .

. -2More than the SP value:

-2More than the SP value:  .

.2.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “Data List” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value?

3.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “Data List” mode, and make sure that the indication is within the SP value. -1More than the SP value:

-1More than the SP value:  .

. -2Less than the SP value:

-2Less than the SP value:  .

.

Is the measurement value within the SP value?

-1More than the SP value:

-1More than the SP value:  .

. -2Less than the SP value:

-2Less than the SP value:  .

.4.CHECK “A/F ALPHA-B1”

- Stop the engine.

- Disconnect PCV hose, and then plug it.

- Start engine.

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “A/F ALPHA-B1”.

Is the measurement value within the SP value?

5.CHANGE ENGINE OIL

- Stop the engine.

- Change engine oil.

note This symptom may occur when a large amount of gasoline is mixed with engine oil because of driving conditions (such as when engine oil temperature does not rise enough since a journey distance is too short during winter). The symptom will not be detected after changing engine oil or changing driving condition.

: INSPECTION END

6.CHECK FUEL PRESSURE

Check fuel pressure. (Refer to Work ProcedureWork Flow .)

.) -1Fuel pressure is too high: Replace “fuel filter and fuel pump assembly”, Refer to Exploded View

-1Fuel pressure is too high: Replace “fuel filter and fuel pump assembly”, Refer to Exploded View , and then

, and then  .

. -2Fuel pressure is too low:

-2Fuel pressure is too low:  .

.

.)

.)Is the inspection result normal?

-1Fuel pressure is too high: Replace “fuel filter and fuel pump assembly”, Refer to Exploded View

-1Fuel pressure is too high: Replace “fuel filter and fuel pump assembly”, Refer to Exploded View , and then

, and then  .

. -2Fuel pressure is too low:

-2Fuel pressure is too low:  .

.7.DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging Replace “fuel filter and fuel pump assembly”, Refer to Exploded View

Replace “fuel filter and fuel pump assembly”, Refer to Exploded View , and then

, and then  .

.

Is the inspection result normal?

Replace “fuel filter and fuel pump assembly”, Refer to Exploded View

Replace “fuel filter and fuel pump assembly”, Refer to Exploded View , and then

, and then  .

.8.CHECK “A/F ALPHA-B1”

- Start engine.

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “A/F ALPHA-B1”.

Is the measurement value within the SP value?

INSPECTION END

INSPECTION END9.PERFORM POWER BALANCE TEST

- Perform "POWER BALANCE" in "Actuator Test" (in "Special Function") mode.

- Make sure that the each cylinder produces a momentary engine speed drop.

Is the inspection result normal?

10.DETECT MALFUNCTIONING PART

Check the following. Replace fuel injector, Refer to Removal and Installation

Replace fuel injector, Refer to Removal and Installation , and then

, and then  .

.

- Ignition coil and its circuit (Refer to Component Function Check

.)

.) - Fuel injector and its circuit (Refer to Component Function Check

.)

.) - Intake air leakage

- Low compression pressure (Refer to Inspection

.)

.)

Is the inspection result normal?

Replace fuel injector, Refer to Removal and Installation

Replace fuel injector, Refer to Removal and Installation , and then

, and then  .

.11.CHECK “A/F ALPHA-B1”

- Start engine.

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “A/F ALPHA-B1”.

Is the measurement value within the SP value?

INSPECTION END

INSPECTION END12.CHECK A/F SENSOR 1 FUNCTION

Perform all DTC CONFIRMATION PROCEDURE related with A/F sensor 1.

- For DTC P0130, Refer to DTC Description

.

. - For DTC P0131, Refer to DTC Description

.

. - For DTC P0132, Refer to DTC Description

.

. - For DTC P014C, P014D, P015A, P015B, Refer to DTC Description

, DTC Description

, DTC Description , DTC Description

, DTC Description , DTC Description

, DTC Description .

. - For DTC P2096, P2097, Refer to DTC Description

,DTC Description

,DTC Description .

.

Is any DTC detected?

14.CHECK “A/F ALPHA-B1”

- Start engine.

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “A/F ALPHA-B1”.

Is the measurement value within the SP value?

INSPECTION END

INSPECTION END15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

- Stop the engine.

- Disconnect ECM harness connector. Check pin terminal and connector for damage, and then reconnect it.

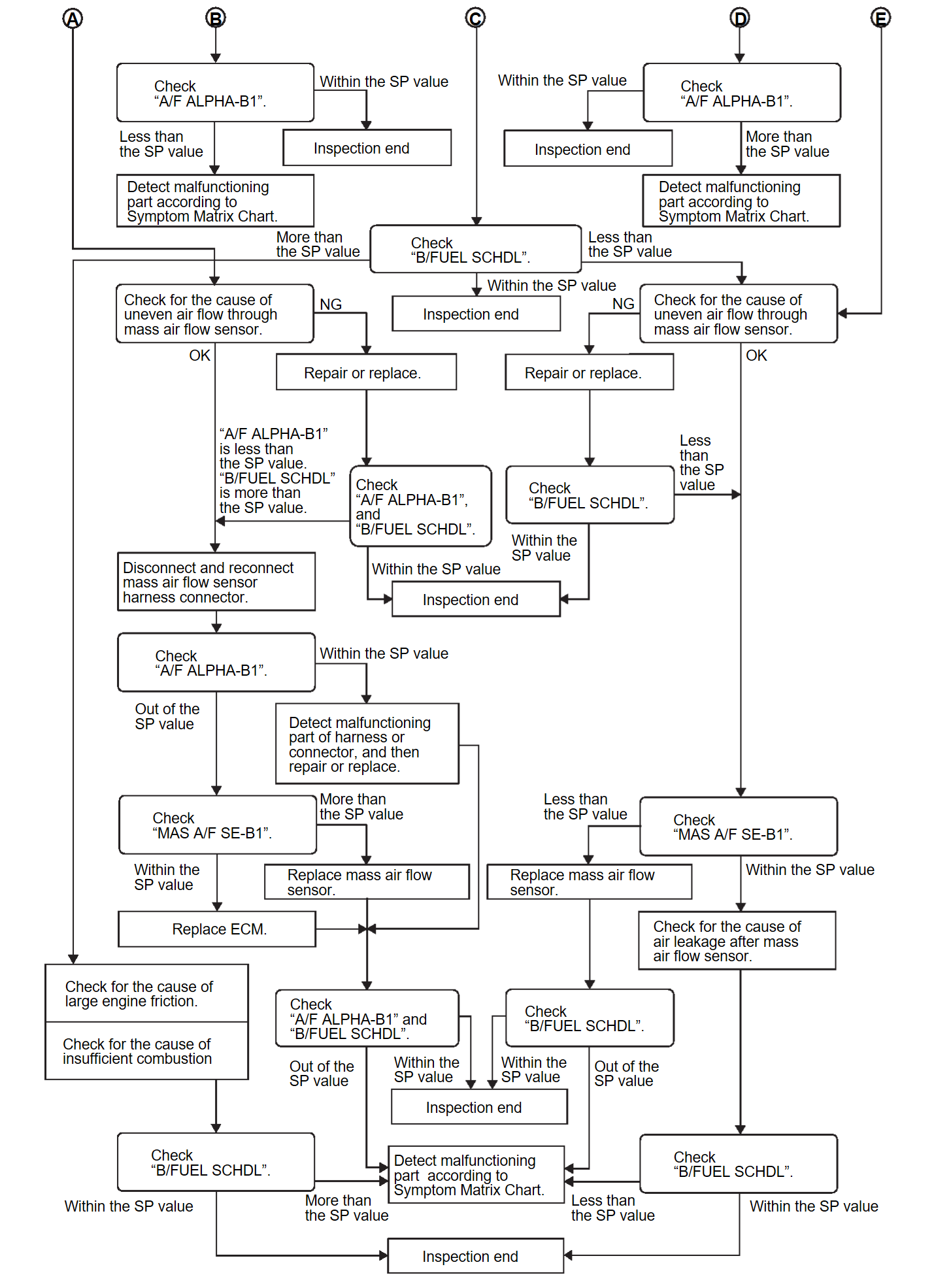

16.CHECK “A/F ALPHA-B1”

- Start engine.

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “A/F ALPHA-B1”.

Is the measurement value within the SP value?

INSPECTION END

INSPECTION END Detect malfunctioning part according to Symptom Table

Detect malfunctioning part according to Symptom Table .

.17.CHECK “B/FUEL SCHDL”

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “B/FUEL SCHDL”.

Is the measurement value within the SP value?

INSPECTION END

INSPECTION END -1More than the SP value:

-1More than the SP value:  .

. -2Less than the SP value:

-2Less than the SP value:  .

.18.DETECT MALFUNCTIONING PART

- Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of power steering, alternator, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

- Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

- Crushed air ducts

- Malfunctioning seal of air cleaner element

- Uneven dirt of air cleaner element

- Improper specification of intake air system

Is the inspection result normal?

20.CHECK “A/F ALPHA-B1”, AND “B/FUEL SCHDL”

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “B/FUEL SCHDL” and “A/F ALPHA-B1”.

Is the measurement value within the SP value?

INSPECTION END

INSPECTION END21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

- Stop the engine.

- Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and then reconnect it again.

22.CHECK “A/F ALPHA-B1”

- Start engine.

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “A/F ALPHA-B1”.

Is the measurement value within the SP value?

Detect malfunctioning part of mass air flow sensor circuit and repair it. Refer to DTC Description

Detect malfunctioning part of mass air flow sensor circuit and repair it. Refer to DTC Description . Then

. Then  .

.23.CHECK “MASS AIR FLOW SENSOR (g/s)”

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “MASS AIR FLOW SENSOR (g/s)”.

Is the measurement value within the SP value?

More than the SP value: Replace mass air flow sensor, Refer to Exploded View

More than the SP value: Replace mass air flow sensor, Refer to Exploded View , and then

, and then  .

.25.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

- Crushed air ducts

- Malfunctioning seal of air cleaner element

- Uneven dirt of air cleaner element

- Improper specification of intake air system

Is the inspection result normal?

26.CHECK “B/FUEL SCHDL”

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “B/FUEL SCHDL”.

Is the measurement value within the SP value?

INSPECTION END

INSPECTION END27.CHECK “MASS AIR FLOW SENSOR (g/s)”

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “MASS AIR FLOW SENSOR (g/s)”.

Is the measurement value within the SP value?

Less than the SP value: Replace mass air flow sensor, Refer to Exploded View

Less than the SP value: Replace mass air flow sensor, Refer to Exploded View , and then

, and then  .

.28.CHECK INTAKE SYSTEM

Check for the cause of air leak after the mass air flow sensor. Refer to the following.

- Disconnection, looseness, and cracks in air duct

- Looseness of oil filler cap

- Disconnection of oil level gauge

- Open stuck, breakage, hose disconnection, or cracks of PCV valve

- Disconnection or cracks of EVAP purge hose, open stuck of EVAP canister purge volume control solenoid valve

- Malfunctioning seal of rocker cover gasket

- Disconnection, looseness, or cracks of hoses, such as vacuum hose, connecting to intake air system parts

- Malfunctioning seal of intake air system, etc.

29.CHECK “A/F ALPHA-B1” AND “B/FUEL SCHDL”

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “B/FUEL SCHDL” and “A/F ALPHA-B1”.

Is the measurement value within the SP value?

INSPECTION END

INSPECTION END Detect malfunctioning part according to Symptom Table

Detect malfunctioning part according to Symptom Table .

.30.CHECK “B/FUEL SCHDL”

- Select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Select “B/FUEL SCHDL”.

Is the measurement value within the SP value?

INSPECTION END

INSPECTION END Detect malfunctioning part according to Symptom Table

Detect malfunctioning part according to Symptom Table .

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)