Removal and Installation

REMOVAL

| warning |

|

1. Release fuel pressure. Refer to Work ProcedureWork Flow .

.

.

.2. Remove engine cover. Refer to Removal and Installation . (With engine cover models)

. (With engine cover models)

. (With engine cover models)

. (With engine cover models)3. Remove high pressure fuel pump insulator bracket. Refer to Exploded View . (Without engine cover models)

. (Without engine cover models)

. (Without engine cover models)

. (Without engine cover models)4. Remove air duct. Refer to Removal and Installation.Removal and Installation

5. Remove battery tray. Refer to Removal and Installation.Removal and Installation

6. Remove high pressure fuel pump insulator.

7. Disconnect quick connector  with the following procedure.

with the following procedure.

with the following procedure.

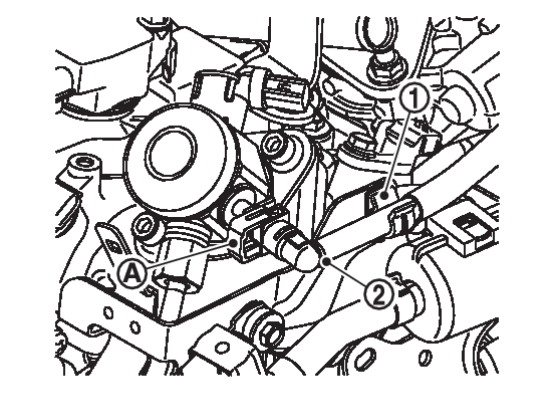

with the following procedure.- Disconnect fuel feed hose

from bracket hose clamp

from bracket hose clamp  .

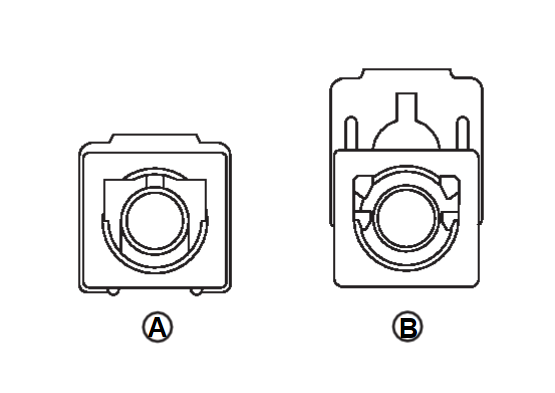

. - Disengage

and pull up

and pull up  the pawl of the fuel feed hose connector retainer

the pawl of the fuel feed hose connector retainer  to disconnect the fuel feed hose from high pressure fuel pump.

to disconnect the fuel feed hose from high pressure fuel pump.note If the fuel feed hose is stuck, hold the fuel pipe by hand and disconnect it by pushing and pulling. caution - Keep parts away from heat source. Especially, be careful when welding is performed around them.

- Never expose parts to battery electrolyte or other acids.

- Never bend or twist connection between quick connector and fuel feed hose during installation/removal.

- Pull quick connector holding

.

. - Never remove the retainer.

- Prepare a tray and waste beforehand as fuel leaks out.

- Never pull with lateral force applied. O-ring inside quick connector may be damaged.

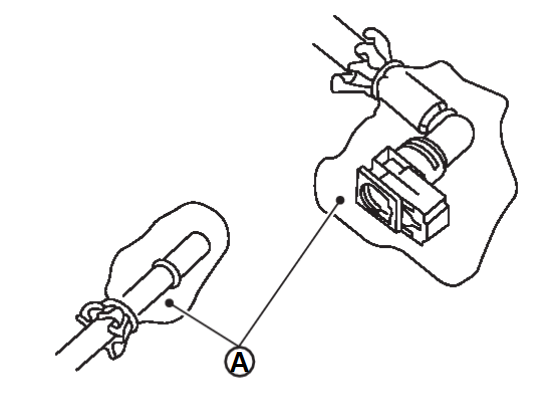

- To prevent damage to each joint and protect it from the entry of foreign matter, cover the joint with plastic bag

or an equivalent.

or an equivalent.

8. Remove intake manifold. Refer to Removal and Installation .

.

.

.9. Remove high pressure fuel tube.

| caution | Do not reuse high pressure fuel tube. |

10. Disconnect high pressure fuel pump harness connector from the high pressure fuel pump.

INSTALLATION

| caution |

|

1. Install high pressure fuel pump according to the following procedure.

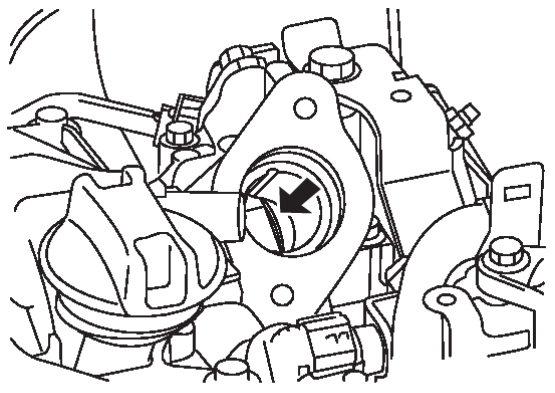

- Check the orientation of pump cam from the mounting area (view arrow) of high pressure fuel pump.

- Aim pump cam at the BDC area (arrow position).

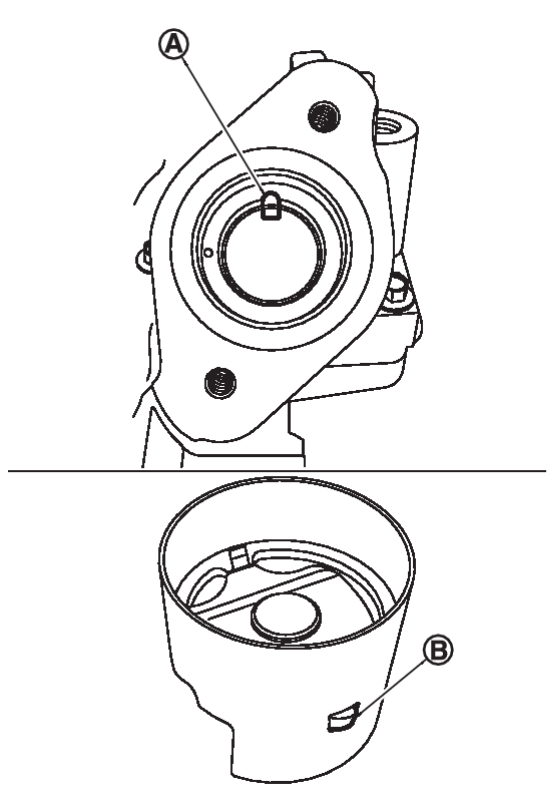

: Camshaft (EXH) note For BDC area, anywhere within the area indicated by arrow can be accepted. - Install O-ring to high pressure fuel pump. When handing new O-ring, paying attention to the following caution items:

caution - Do not reuse O-ring.

- Handle O-ring with bare hands. Never wear gloves.

- Lubricate O-ring with new engine oil.

- Never clean O-ring with solvent.

- Check that O-ring and its mating part are free of foreign material.

- Never damage O-ring with tools and fingernails during the installation. In addition, twisting or stretching O-ring is not allowed. If O-ring is stretched during the installation to high pressure fuel pump, never install high pressure fuel pump immediately.

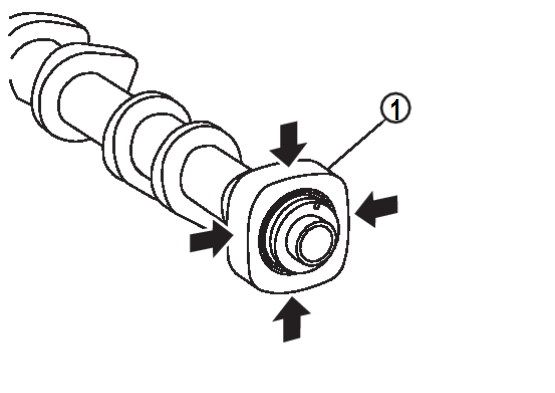

- Lubricate high pressure fuel pump lifter and high pressure fuel pump lifter bore with clean engine oil.

- Reinstall the high pressure fuel pump lifter.

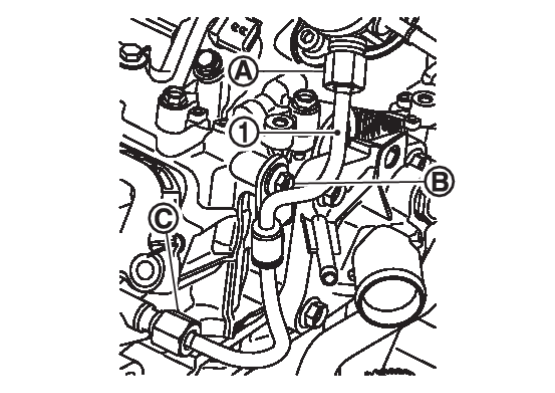

note When installing high pressure fuel pump lifter, note the orientation of protrusion  and cutout

and cutout  in camshaft bracket, they should be aligned.

in camshaft bracket, they should be aligned. - Apply oil to the fitting area of high pressure fuel pump O-ring and camshaft bracket side to install high pressure fuel pump.

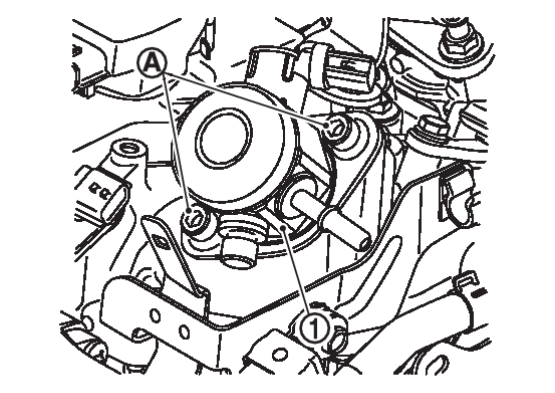

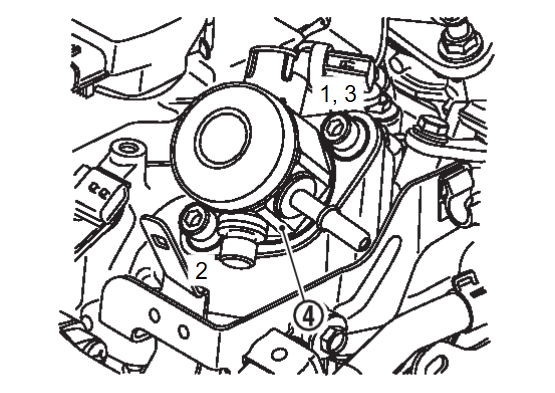

- Install high pressure fuel pump. To prevent damage to high pressure fuel pump and camshaft bracket, the following instructions must be observed.

- Tighten the high pressure fuel pump bolt

until it hits the high pressure fuel pump, and then tighten both bolts by 180 degrees.

until it hits the high pressure fuel pump, and then tighten both bolts by 180 degrees.

: High pressure fuel pump - Temporarily alternately tighten bolt

by three turn at time by hand.

by three turn at time by hand.

: High pressure fuel pump - While pushing the center of the high pressure fuel pump by hand until it hits the camshaft bracket, tighten the high pressure fuel pump bolt by the following procedure:

- Tighten the bolt (1) as shown in the figure (temporarily).

: 2.0 N·m (0.2 kg-m, 18 in-lb)

: High pressure fuel pump - Tighten the bolt (2) as shown in the figure (spceified torque).

: 10.0 N·m (1.0 kg-m, 89 in-lb) - Tighten the bolt (3) as shown in the figure (spceified torque).

: 10.0 N·m (1.0 kg-m, 89 in-lb)

- Tighten the bolt (1) as shown in the figure (temporarily).

- Tighten the high pressure fuel pump bolt

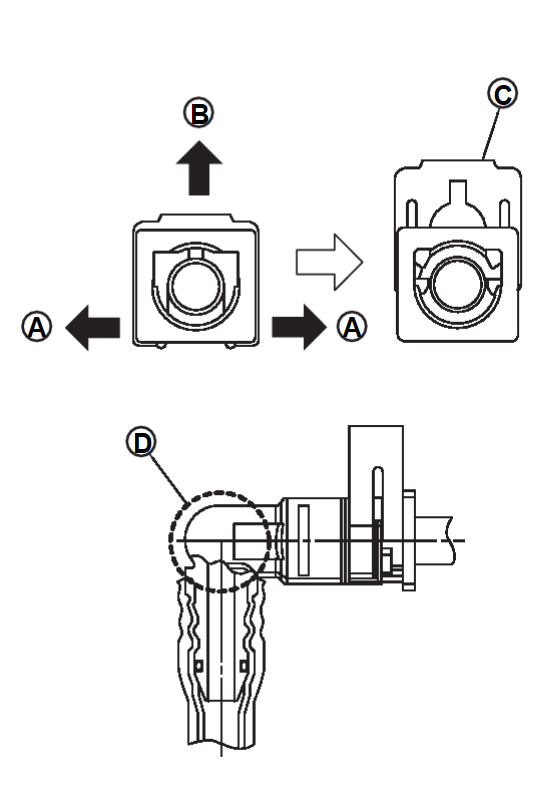

2. Connect fuel feed hose with the following procedure, and them install the fuel feed hose.

- Check no foreign substances are deposited in and around matching pipe and quick connector, and no damage on them.

- Quick connector shall be inserted gradually, aligning with the axis of the matching pipe.

- Insert the retainer until it clicks and check the retainer is locked. After insertion, pull the connector and check that the connector is locked.

: Lock position

: Unlock position caution If retainer cannot be installed smoothly, quick connector may be have not been installed correctly. Check connection again.

3. Install the fuel tube with the following procedure.

| caution |

|

- Temporarily tighten until the high pressure fuel tube

flare nuts

flare nuts  and

and  contact the seat.

contact the seat.caution When temporarily tightening flare nut, place pipe in the center of the nut inner diameter. - Temporarily tighten the high-pressure fuel tube bracket mounting bolt

.

. - Tighten flare nut

to the specified torque.

to the specified torque.

: 23.0 N·m (2.3 kg-m, 17 ft-lb) caution Before tightening, check that the tool is attached at a 90° angle to the flare nut when working. - Tighten flare nut

to the specified torque.

to the specified torque.

: 23.0 N·m (2.3 kg-m, 17 ft-lb) caution Before tightening, check that the tool is attached at a 90° angle to the flare nut when working. - Again tighten flare nut

to the specified torque.

to the specified torque.

: 23.0 N·m (2.3 kg-m, 17 ft-lb) caution Before tightening, check that the tool is attached at a 90° angle to the flare nut when working. - Again tighten flare nut

to the specified torque.

to the specified torque.

: 23.0 N·m (2.3 kg-m, 17 ft-lb) caution Before tightening, check that the tool is attached at a 90° angle to the flare nut when working. - Tighten tighten the high-pressure fuel tube bracket mounting bolt

specified torque.

specified torque.

: 25.0 N·m (2.6 kg-m, 18 ft-lb)

4. Install in the reverse order of removal after this step.

| caution | After checking fuel leakage, maintain ten minutes of idling to bleed the fuel line. |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)