Inspection and Adjustment

INSPECTION

Perform inspection as follows after removal, installation or replacement of camshaft or valve-related parts, or if there is unusual engine conditions regarding valve clearance.

1. Remove rocker cover. Refer to Removal and Installation .

.

.

.2. Measure the valve clearance with the following procedure:

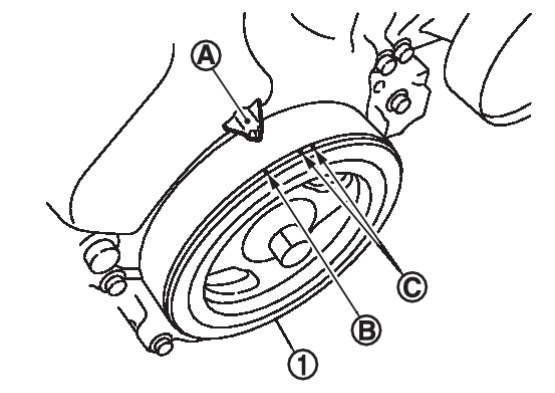

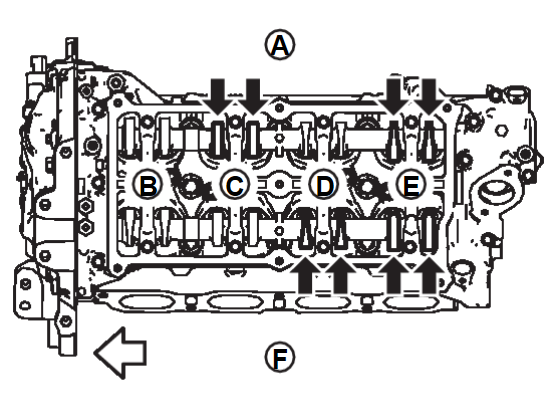

(1) Set No. 1 cylinder at TDC of its compression stroke.

- Rotate crankshaft pulley

clockwise and align TDC mark (no paint)

clockwise and align TDC mark (no paint)  to timing indicator

to timing indicator  on front cover.

on front cover.

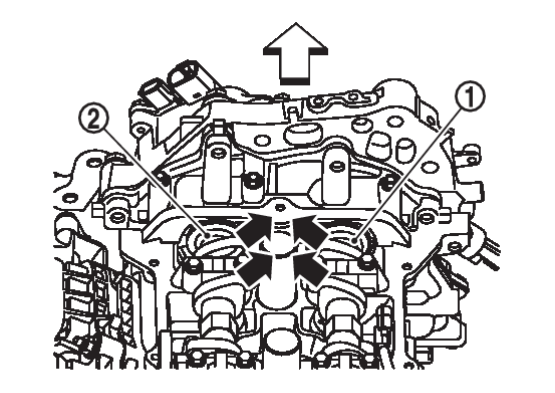

: Paint marks (Not used for service) - At the same time, check that both intake and exhaust cam noses of No. 1 cylinder face inside (

) as shown in the figure.

) as shown in the figure.

: Camshaft (EXH)

: Camshaft (INT)

: Engine front - If they do not face inside, rotate crankshaft pulley once more (360 degrees) and align as shown in the figure.

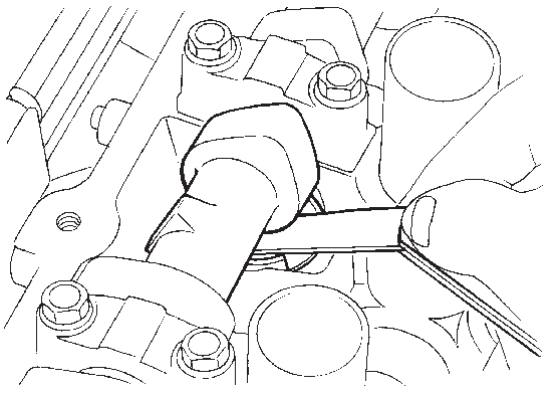

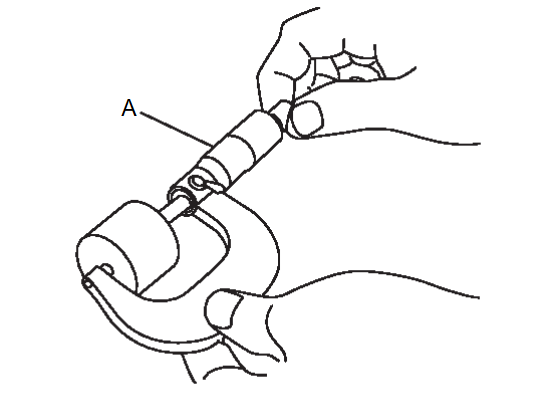

(2) Use a feeler gauge, measure the clearance between valve lifter and camshaft.

| Valve clearance | : Refer to Camshaft . . |

- By referring to the figure, measure the valve clearances at locations marked “×” as shown in the table below [locations indicated with black arrow (

) in the figure] with a feeler gauge.

) in the figure] with a feeler gauge.

: Exhaust side

: No. 1 cylinder

: No. 2 cylinder

: No. 3 cylinder

: No. 4 cylinder

: Intake side

: Engine front

| Measuring position | No. 1 CYL. | No. 2 CYL. | No. 3 CYL. | No. 4 CYL. | |

| No. 1 cylinder at compression TDC | INT | × | × | ||

| EXH | × | × | |||

(3) Set No. 4 cylinder at TDC of its compression stroke, rotate crankshaft pulley  one revolution (360 degrees) and align TDC mark (no paint)

one revolution (360 degrees) and align TDC mark (no paint)  to timing indicator

to timing indicator  on front cover.

on front cover.

one revolution (360 degrees) and align TDC mark (no paint)

one revolution (360 degrees) and align TDC mark (no paint)  to timing indicator

to timing indicator  on front cover.

on front cover.  | : Paint marks |

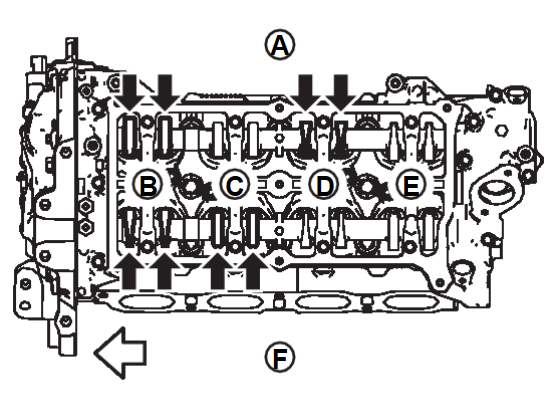

- By referring to the figure, measure the valve clearance at locations marked “×” as shown in the table below [locations indicated with black arrow (

) in the figure] with a feeler gauge.

) in the figure] with a feeler gauge.

: Exhaust side

: No. 1 cylinder

: No. 2 cylinder

: No. 3 cylinder

: No. 4 cylinder

: Intake side

: Engine front

| Measuring position | No. 1 CYL. | No. 2 CYL. | No. 3 CYL. | No. 4 CYL. | |

| No. 4 cylinder at compression TDC | INT | × | × | ||

| EXH | × | × | |||

3. If out of standard, perform adjustment. Refer to "ADJUSTMENT".

ADJUSTMENT

- Perform adjustment depending on selected head thickness of valve lifter.

1. Remove camshaft. Refer to Removal and Installation .

.

.

.2. Remove valve lifters at the locations that are out of the standard.

4. Use the equation below to calculate valve lifter thickness for replacement.

| Valve lifter thickness calculation: | t = t1 + (C1 – C2) | ||||

| t | = Valve lifter thickness to be replaced | ||||

| t1 | = Removed valve lifter thickness | ||||

| C1 | = Measured valve clearance | ||||

| C2 | = Standard valve clearance: | ||||

| Intake | : 0.31 mm (0.011 in) | ||||

| Exhaust | : 0.32 mm (0.012 in) | ||||

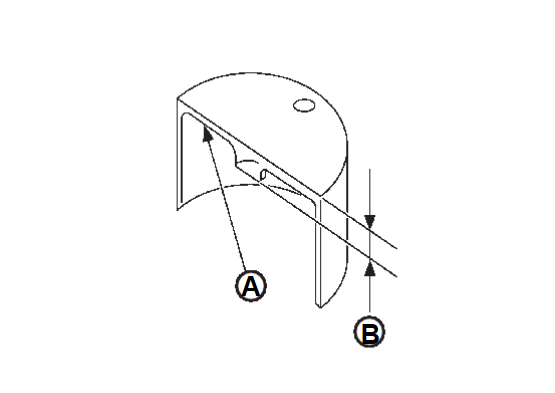

- Thickness of new valve lifter

can be identified by stamp mark

can be identified by stamp mark  on the reverse side (inside the cylinder).

on the reverse side (inside the cylinder). - Stamp mark “302” indicates 3.02 mm (0.1189 in) in thickness.

| note | Available thickness of valve lifter: 26 sizes range 3.00 to 3.50 mm (0.1181 to 0.1378 in) in steps of 0.02 mm (0.0008 in) (when manufactured at factory). Refer to Camshaft . . |

5. Install the selected valve lifter.

6. Install camshaft. Refer to Removal and Installation .

.

.

.7. Install timing chain and related parts. Refer to Removal and Installation .

.

.

.8. Manually rotate crankshaft pulley a few rotations.

9. Check that the valve clearances is within the standard. Refer to “INSPECTION”.

10. Install remaining parts in the reverse order of removal.

11. Warm up the engine, and check for unusual noise and vibration.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)