Work Procedure

1.INSPECTION START

- Check service records for any recent repairs that may indicate a related malfunction, or a current need for scheduled maintenance.

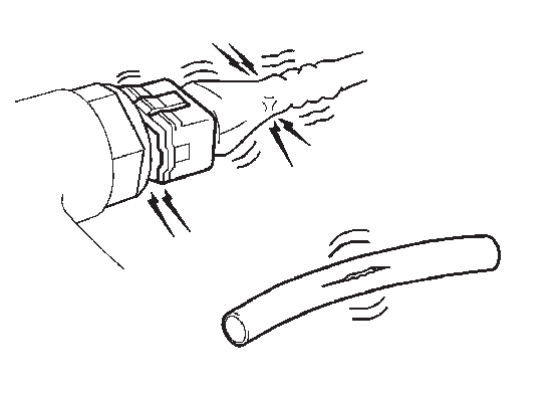

- Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

- Confirm that electrical or mechanical loads are not applied.

- Headlight switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

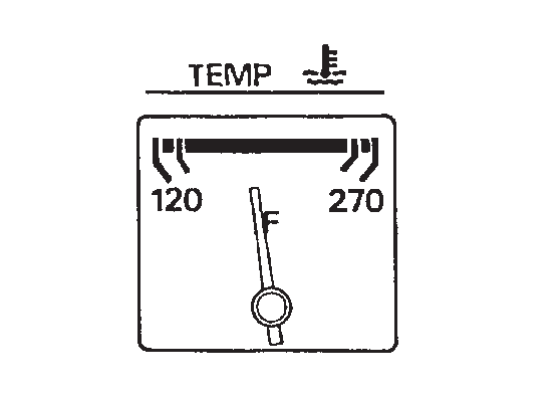

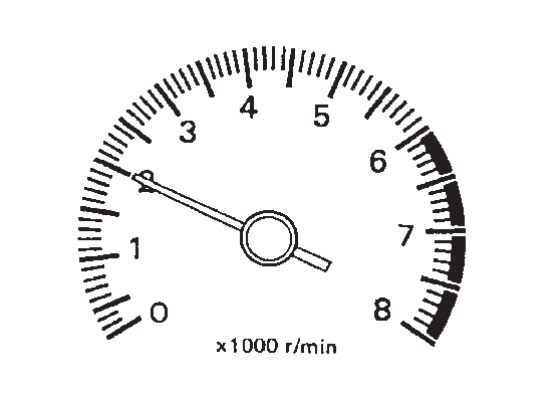

- Start engine and warm it up until engine coolant temperature indicator points the middle of gauge.Ensure engine stays below 1,000 rpm.

- Run engine at about 2,000 rpm for about 2 minutes under no load.

- Make sure that no DTC is displayed with M.U.T.-III SE or GST.

Is any DTC detected?

2.REPAIR OR REPLACE

3.CHECK TARGET IDLE SPEED

- Run engine at about 2,000 rpm for about 2 minutes under no load.

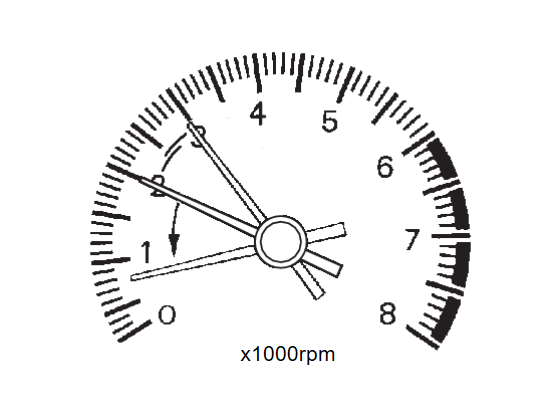

- Rev engine (2,000 to 3,000 rpm) two or three times under no load, then run engine at idle speed for about 1 minute.

- Check idle speed.For procedure, Refer to IDLE SPEED : Periodic Maintenance

.For specification, Refer to IGNITION TIMING : Service Data

.For specification, Refer to IGNITION TIMING : Service Data .

.

Is the inspection result normal?

6.PERFORM IDLE AIR VOLUME LEARNING

Refer to Description .

.

.

.Is Idle Air Volume Learning carried out successfully?

7.CHECK TARGET IDLE SPEED AGAIN

- Start engine and warm it up to normal operating temperature.

- Check idle speed.For procedure, Refer to IDLE SPEED : Periodic Maintenance

.For specification, Refer to IGNITION TIMING : Service Data

.For specification, Refer to IGNITION TIMING : Service Data .

.

Is the inspection result normal?

8.DETECT MALFUNCTIONING PART

Check the Following.

- Check camshaft position sensor and circuit. Refer to DTC Description

.

. - Check crankshaft position sensor and circuit. Refer to DTC Description

.

.

Is the inspection result normal?

9.CHECK ECM FUNCTION

- Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but this is a rare case.)

- Perform initialization of NVIS (NATS) system and registration of all NVIS (NATS) ignition key IDs. Refer to Work Procedure

.

.

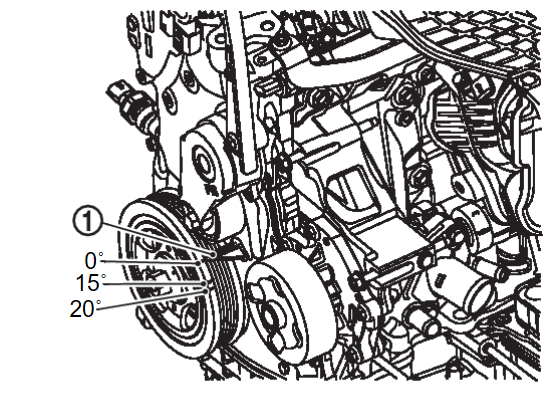

10.CHECK IGNITION TIMING

- Run engine at idle.

- Check ignition timing with a timing light.

Timing indicator For procedure,Refer to IGNITION TIMING : Periodic Maintenance . For specification, Refer to IGNITION TIMING : Service Data

. For specification, Refer to IGNITION TIMING : Service Data .

.

Is the inspection result normal?

INSPECTION END.

INSPECTION END.13.PERFORM IDLE AIR VOLUME LEARNING

Refer to Description .

.

.

.Is Idle Air Volume Learning carried out successfully?

14.CHECK TARGET IDLE SPEED AGAIN

- Start engine and warm it up to normal operating temperature.

- Check idle speed.For procedure, Refer to IDLE SPEED : Periodic Maintenance

.For specification, Refer to IGNITION TIMING : Service Data

.For specification, Refer to IGNITION TIMING : Service Data .

.

Is the inspection result normal?

15.CHECK IGNITION TIMING AGAIN

- Run engine at idle.

- Check ignition timing with a timing light.

Timing indicator For procedure, Refer to IGNITION TIMING : Periodic Maintenance . For specification, Refer to IGNITION TIMING : Service Data

. For specification, Refer to IGNITION TIMING : Service Data .

.

Is the inspection result normal?

INSPECTION END.

INSPECTION END.16.CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to Removal and Installation .

.

.

.Is the inspection result normal?

17.DETECT MALFUNCTIONING PART

Check the following.

- Check camshaft position sensor and circuit. Refer to DTC Description

.

. - Check crankshaft position sensor and circuit. Refer to DTC Description

.

.

Is the inspection result normal?

18.CHECK ECM FUNCTION

- Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but this is a rare case.)

- Perform initialization of NVIS (NATS) system and registration of all NVIS (NATS) ignition key IDs. Refer to Work Procedure

.

.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)