DTC C1608: Implausible diagnosis data

OPERATION

The ASC-ECU stores diagnostic trouble codes and failure information in the EEPROM*.

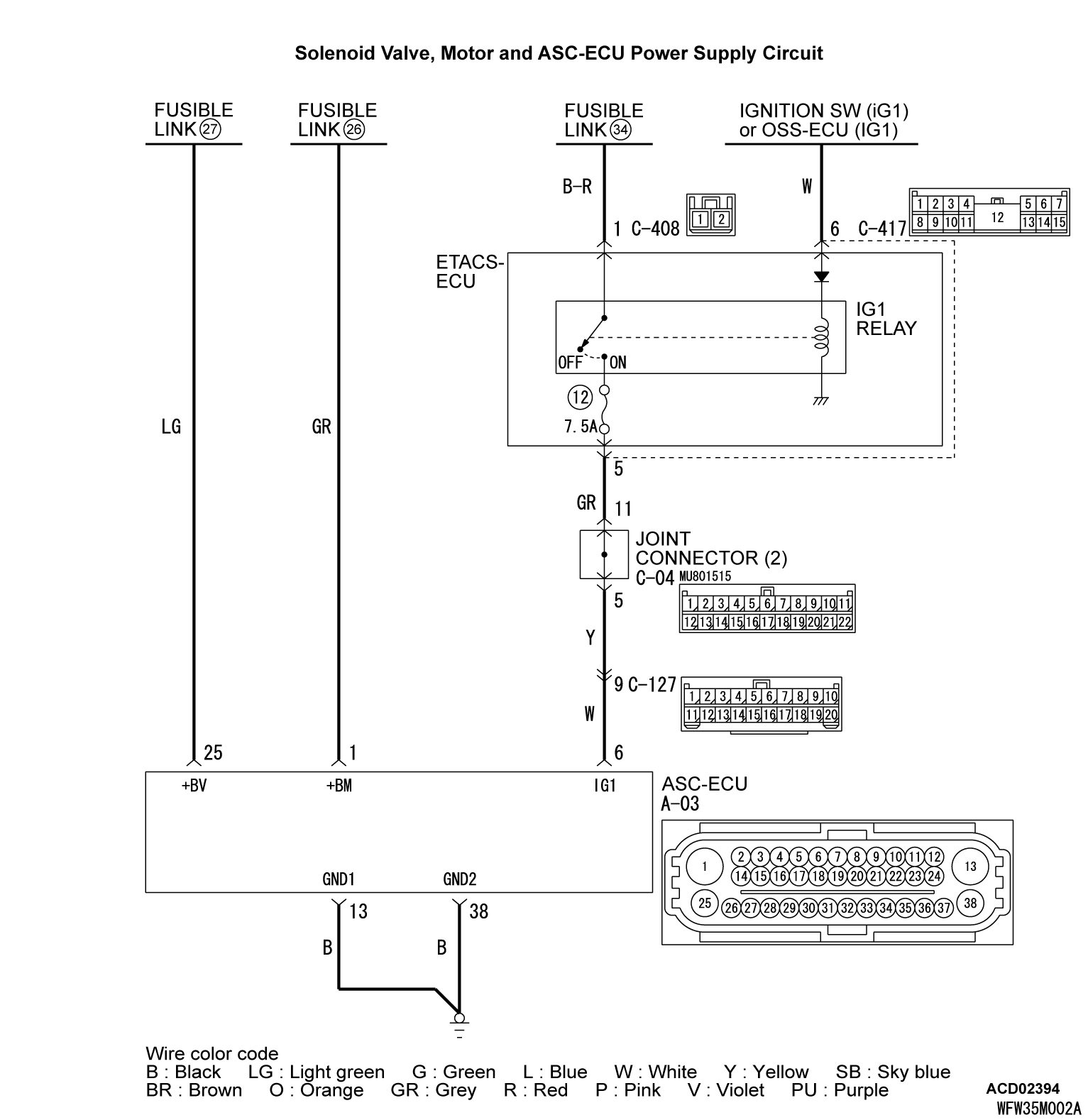

ASC-ECU (EEPROM*)contains the power supply circuit (terminal No.25).

| note | *: EEPROM (Electrical Erasable and Programmable ROM) |

DTC SET CONDITIONS

- This diagnostic trouble code is stored when the failure information stored in the EEPROM is not reliable. The failure information stored in the past is not output, and only this diagnostic trouble code is stored.

- This diagnostic trouble code may occur when ASC-ECU power supply shutdown or drop between ASC-ECU is writing a data to the EEPROM.

PROBABLE CAUSES

- Disconnection of the ASC-ECU connector or the battery terminal when the ignition switch is ON

- Loose battery terminal

- Abnormality in battery

- Damaged wiring harness and connectors

- ASC-ECU malfunction

DIAGNOSIS

STEP 1.Using scan tool MB991958, diagnose the CAN bus line.

Use scan tool to diagnose the CAN bus lines.

Is the check result normal?

STEP 2. Diagnostic trouble code recheck after resetting CAN bus lines

STEP 3. Battery check

STEP 4. Charging system check

Refer to GROUP 16 - On-vehicle Service/Output Current Test  .

. Repair or replace the charging system component(s).

Repair or replace the charging system component(s).

.

.Is the charging system in good condition?

Repair or replace the charging system component(s).

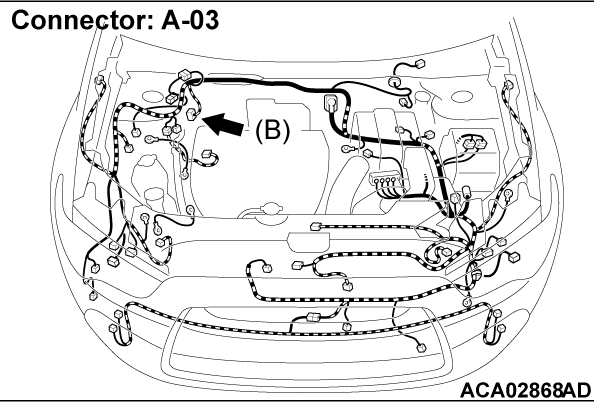

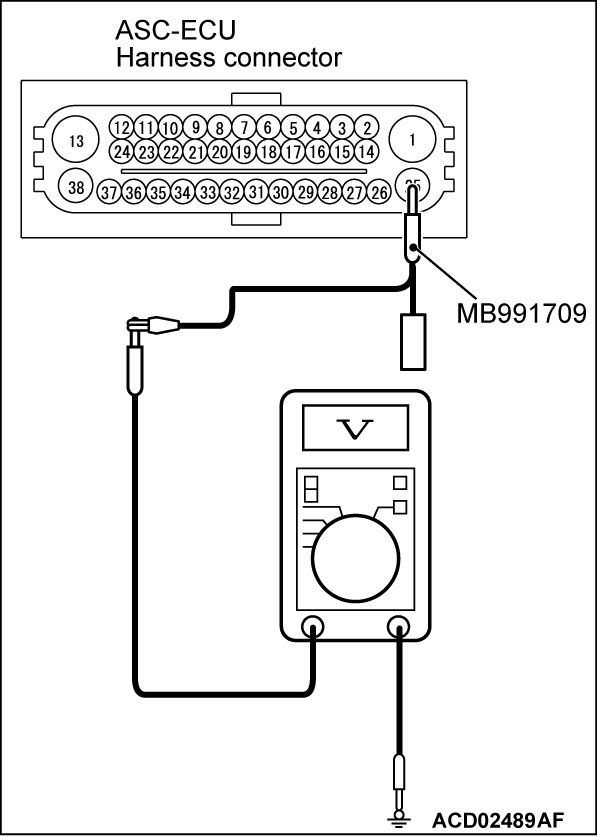

Repair or replace the charging system component(s).STEP 5. Voltage measurement at the A-03 ASC-ECU connector

(1) Disconnect the connector, connect special tool MB991997 to the harness-side connector, and measure the voltage at the special tool connector side.

| note | Do not connect the special tool MB991997 to ASC-ECU. |

(2) Measure the voltage between the terminal No.25 and the body ground.

OK: Approximately system voltage

Is the check result normal?

STEP 6. Connector check: A-03 ASC-ECU connector

Is the check result normal?

The open or short circuit may be present in the power supply circuit. Repair the wiring harness between the A-03 ASC-ECU connector terminal No.25 and fusible link No.27.

The open or short circuit may be present in the power supply circuit. Repair the wiring harness between the A-03 ASC-ECU connector terminal No.25 and fusible link No.27. Repair the defective connector.

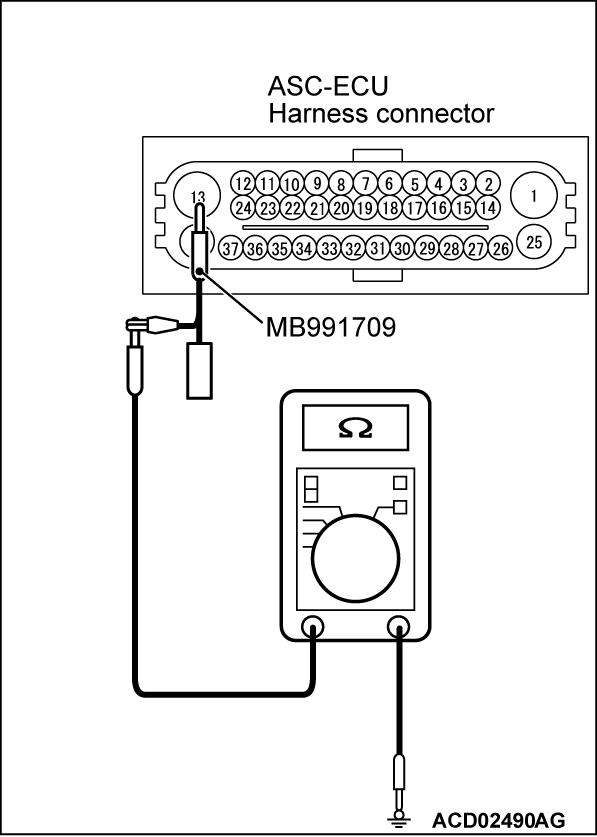

Repair the defective connector.STEP 7. Resistance measurement at A-03 ASC-ECU connector

(1) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the resistance at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(2) Resistance between the terminal No.13 and the body ground, and between the terminal No.38 and the body ground

OK: Continuity exists (2 ohms or less)

Is the check result normal?

STEP 8. Connector check: A-03 ASC-ECU connector

Is the check result normal?

An open circuit may be present in the ground circuit. Repair the wiring harness between the A-03 ASC-ECU terminal No.13 and body ground, and between the A-03 ASC-ECU terminal No.38 and body ground.

An open circuit may be present in the ground circuit. Repair the wiring harness between the A-03 ASC-ECU terminal No.13 and body ground, and between the A-03 ASC-ECU terminal No.38 and body ground. Repair the defective connector.

Repair the defective connector.STEP 9. Check whether the DTC is stored again.

(1) Erase the DTC.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3) Turn the ignition switch to the "ON" position.

(4) Drive the vehicle at 12mph (20 km/h) or higher.

| note | The ABS warning light does not turn OFF in some cases unless the vehicle runs at 12mph (20 km/h) or higher. |

Is DTC C1608 stored?

STEP 10. Check whether the DTC is stored again.

(1) Erase the DTC.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3) Turn the ignition switch to the "ON" position.

(4) Drive the vehicle at 12mph (20 km/h) or higher.

| note | The ABS warning light does not turn OFF in some cases unless the vehicle runs at 12mph (20 km/h) or higher. |

Is DTC C1608 stored?

STEP 11. Check the other DTCs.

(1) Erase the DTC.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3) Turn the ignition switch to the "ON" position.

(4) Drive the vehicle at 12mph (20 km/h) or higher.

| note | The ABS warning light does not turn OFF in some cases unless the vehicle runs at 12mph (20 km/h) or higher. |

Is any DTC stored?

The procedure is complete.

The procedure is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)