Inspection Procedure 3: Brake warning light Stays ON with the parking brake lever released.

| caution |

OPERATION

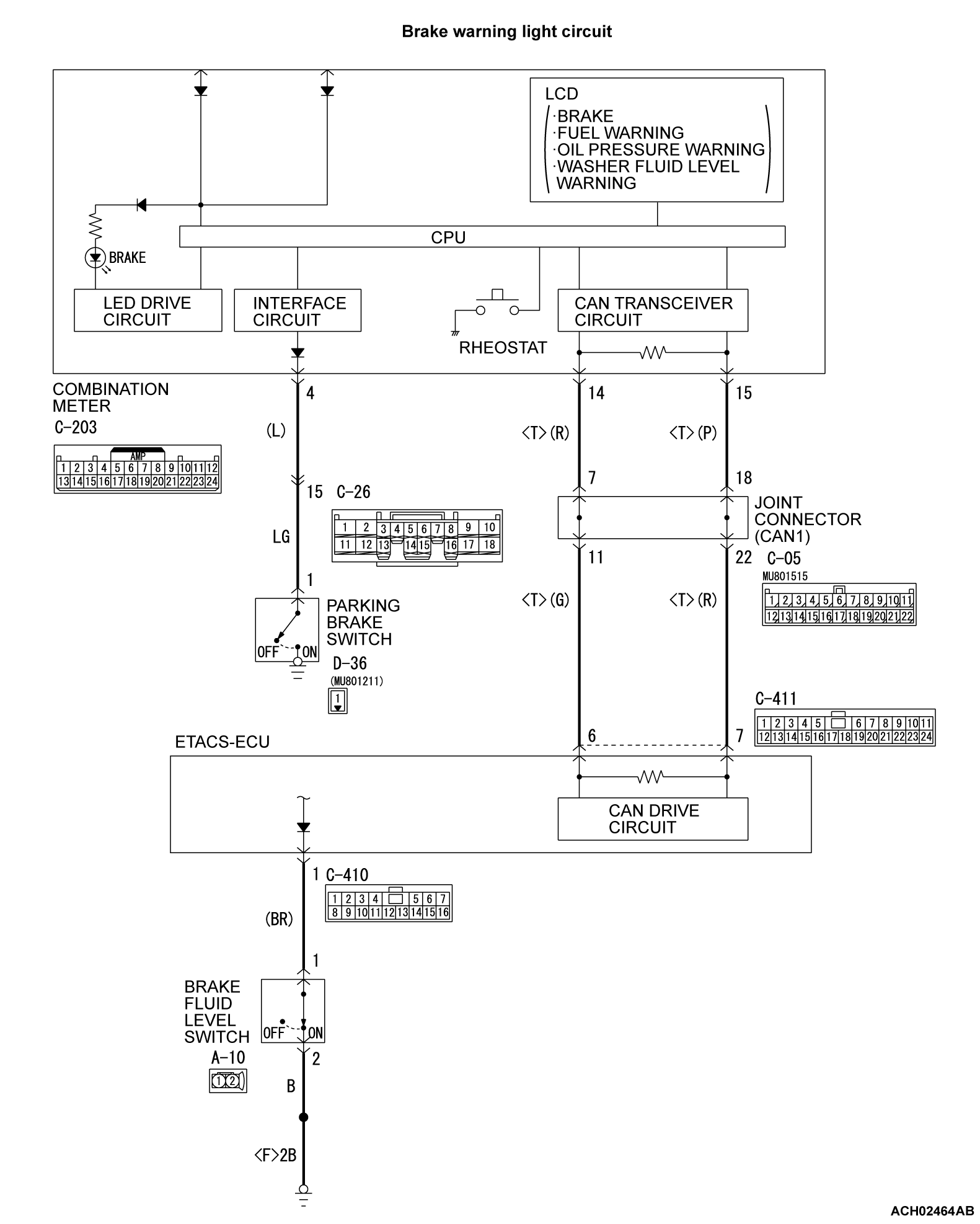

- When the parking brake switch is turned "ON", the combination meter terminal No.4 is grounded, and the brake warning light illuminates.

- When reduction of the brake fluid amount is detected, the brake fluid level switch is turned from "ON" to OFF. ETACS-ECU monitors the brake fluid level switch, and instructs the combination meter via the CAN bus line to illuminate the brake warning light.

TECHNICAL DESCRIPTION (COMMENT)

This may be caused by ground fault in the parking brake switch circuit.

PROBABLE CAUSES

- The brake pad thickness is at the limit value or less.

- The brake fluid amount is at the "LOWER" level or lower.

- Poor adjustment of the parking brake lever

- Damaged wiring harness and connectors

- Parking brake switch malfunction

- Brake fluid level switch malfunction

- Combination meter malfunction

- ETACS-ECU malfunction

DIAGNOSIS

STEP 1. Using scan tool MB991958, diagnose the CAN bus lines.

Use scan tool to diagnose the CAN bus lines.

Is the check result normal?

STEP 2. DTC check after resetting CAN bus lines

Use scan tool to check that the DTC is set in the combination meter and ETACS-ECU. Carry out the diagnosis for the DTC.

Carry out the diagnosis for the DTC.

Is any DTC set?

Carry out the diagnosis for the DTC.

Carry out the diagnosis for the DTC.STEP 3. Brake fluid level check

Check that the brake fluid is filled up to the "MIN" level or higher.

Is the check result normal?

STEP 4. Brake pad check

STEP 5. Brake fluid level switch check

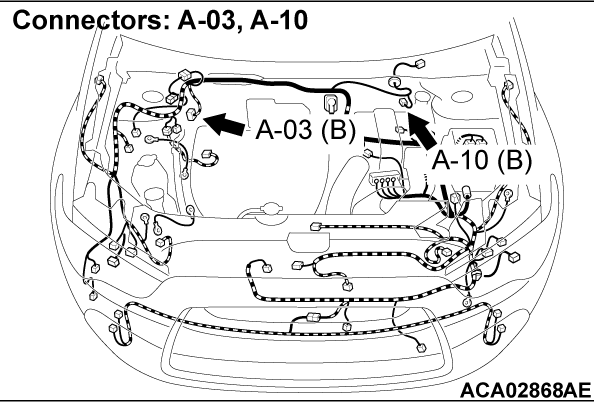

STEP 6. Connector check: A-10 brake fluid level switch connector, C-410 ETACS-ECU connector

STEP 7. Measure the voltage at A-10 brake fluid level switch connector.

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between the terminal No. 1 and the body ground.

OK: Approximately system voltage

Is the check result normal?

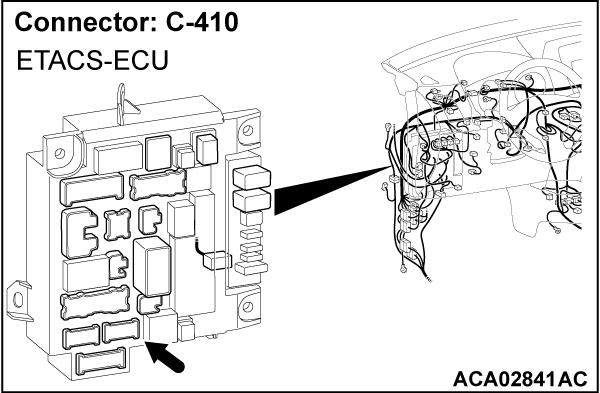

STEP 8. Measure the voltage at the C-410 ETACS-ECU connector.

| caution | With the C-410 ETACS-ECU connector kept connected, disconnect the A-10 brake fluid level switch connector. |

(1) Turn the ignition switch to the "ON" position.

(2) Measure the voltage between terminal No.1 and the body ground by backprobing.

OK: Approximately system voltage

Is the check result normal?

Repair the wiring harness between the C-410 ETACS-ECU connector terminal No. 1 and the A-10 brake fluid level switch connector terminal No. 1.

Repair the wiring harness between the C-410 ETACS-ECU connector terminal No. 1 and the A-10 brake fluid level switch connector terminal No. 1.STEP 9. Wiring harness check: between A-10 brake fluid level switch connector and body ground

Check for open circuit in the harness wire between A-10 brake fluid level switch connector terminal No.2 and body ground. Repair the wiring harness.

Repair the wiring harness.

Is the check result normal?

Repair the wiring harness.

Repair the wiring harness.STEP 10. Parking brake lever stroke check

Refer to GROUP 36 - On-vehicle Service/Parking Brake Lever Stroke Check and Adjustment  .

.

.

.Is the check result normal?

STEP 11. Parking brake switch check

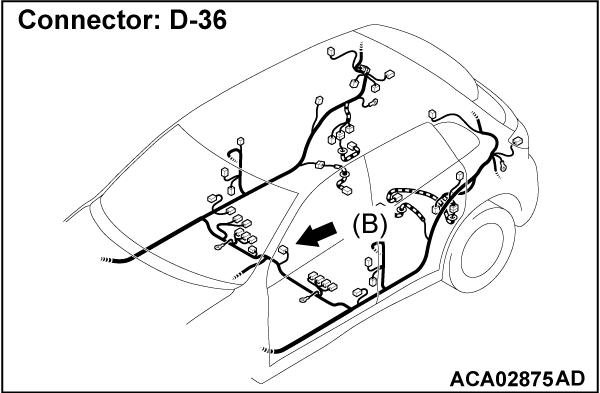

STEP 12. Connector check: D-36 parking brake switch connector

STEP 13. Measure the voltage at D-36 parking brake switch connector.

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between the terminal No.1 and the body ground.

OK: Approximately system voltage

Is the check result normal?

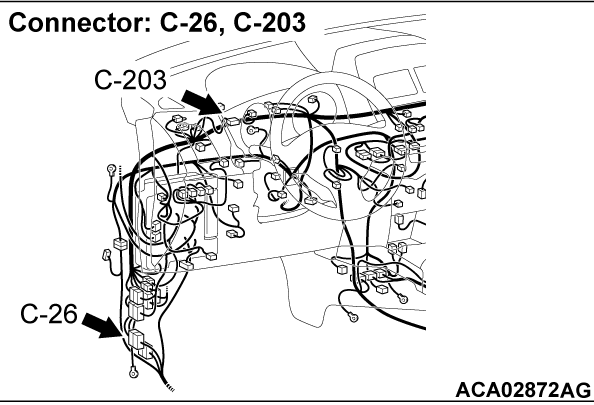

STEP 14. Connector check: C-203 Combination meter connector, C-26 intermediate connector

STEP 15. Wiring harness check: between the C-203 combination meter connector and the D-36 parking brake switch connector

Check for short circuit in the harness wire between the C-203 combination meter connector terminal No.4 and the D-36 parking brake switch connector terminal No.1. Repair the wiring harness.

Repair the wiring harness.

Is the check result normal?

Repair the wiring harness.

Repair the wiring harness.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)