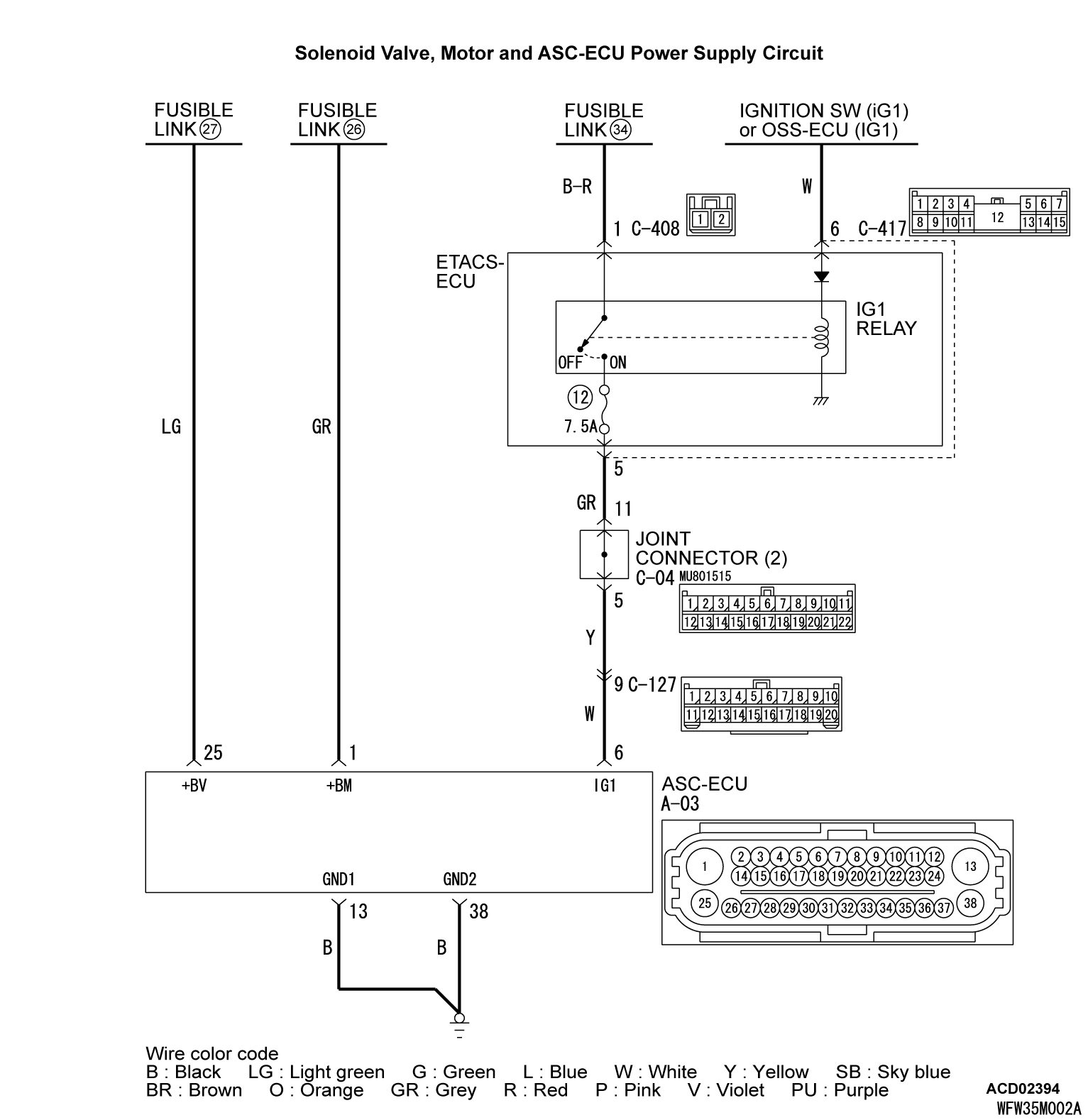

Inspection Procedure 13: ASC-ECU power supply circuit system

OPERATION

- ASC-ECU contains the power supply circuit (terminal No. 25) for the solenoid valve. The solenoid valve is energized by the valve relay, which is incorporated in ASC-ECU.

- ASC-ECU contains the power supply circuit (terminal No.6) for ASC-ECU. When the ignition switch (IG1) is turned ON, the voltage is applied to the relay incorporated in ETACS-ECU to turn ON the relay, and the power is supplied from the fusible link No.34 through multi-purpose fuse No.12.

- ASC-ECU contains the power supply circuit (terminal No.1) for the pump motor. The pump motor is energized by the motor switch, which is incorporated in ASC-ECU.

- When malfunction occurs in ASC-ECU power supply, the communication with scan tool becomes unavailable.

PROBABLE CAUSES

- Damaged wiring harness and connectors

- Malfunction of fuse or fusible link

- Improper tightening of battery terminal

- Improper tightening of grounding bolt

- Battery failure

- Charging system failed

- ASC-ECU malfunction

DIAGNOSIS

STEP 2. Charging system check

Refer to GROUP 16 - On-vehicle Service/Output Current Test  .

. Repair or replace the charging system component(s).

Repair or replace the charging system component(s).

.

.Is the charging system in good condition?

Repair or replace the charging system component(s).

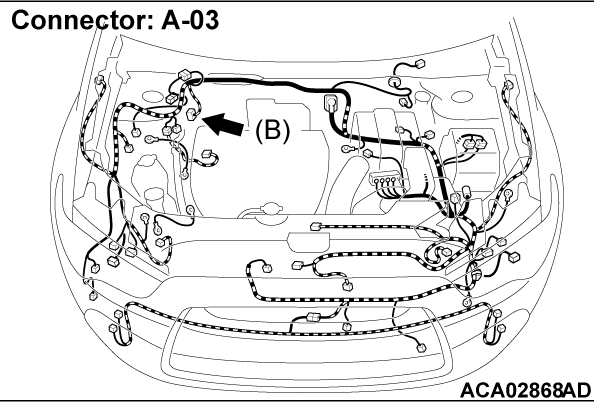

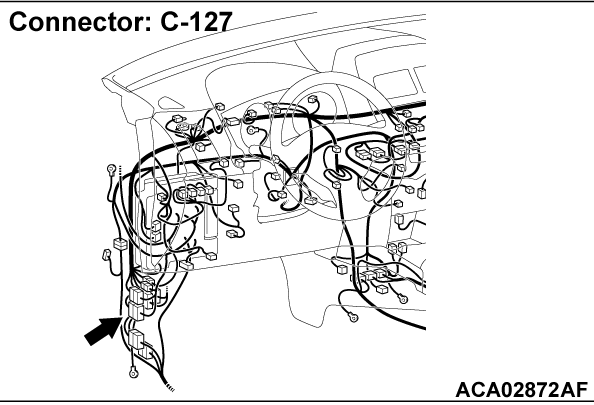

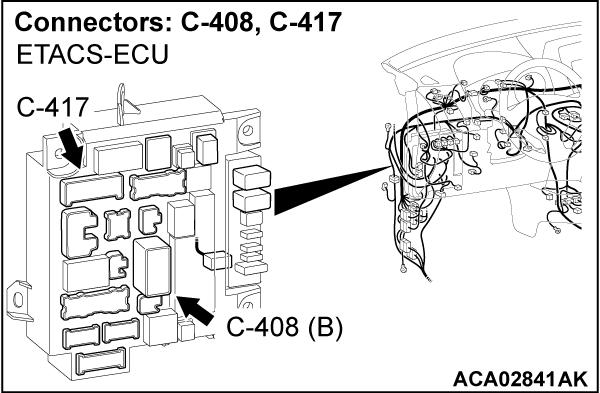

Repair or replace the charging system component(s).STEP 3. Connector check: A-03 ASC-ECU connector, C-127 intermediate connector and C-417 ETACS-ECU connector.

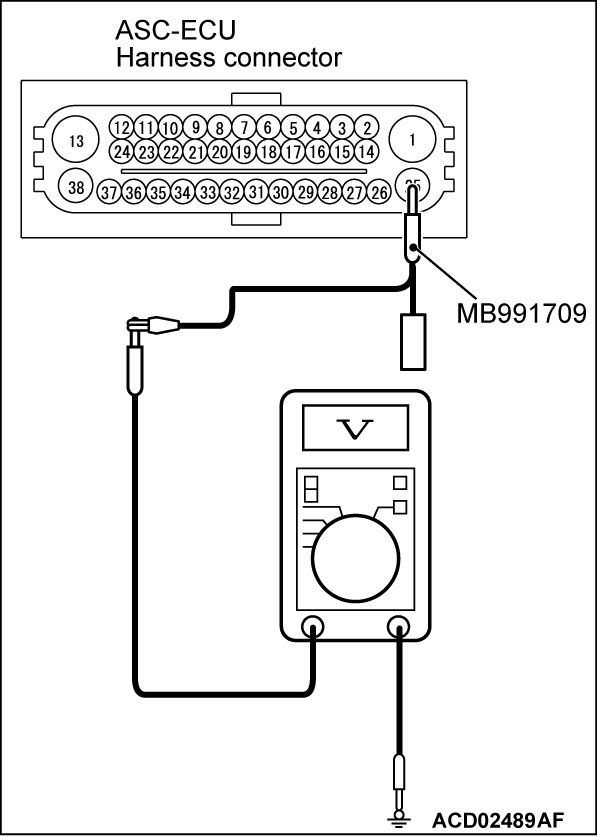

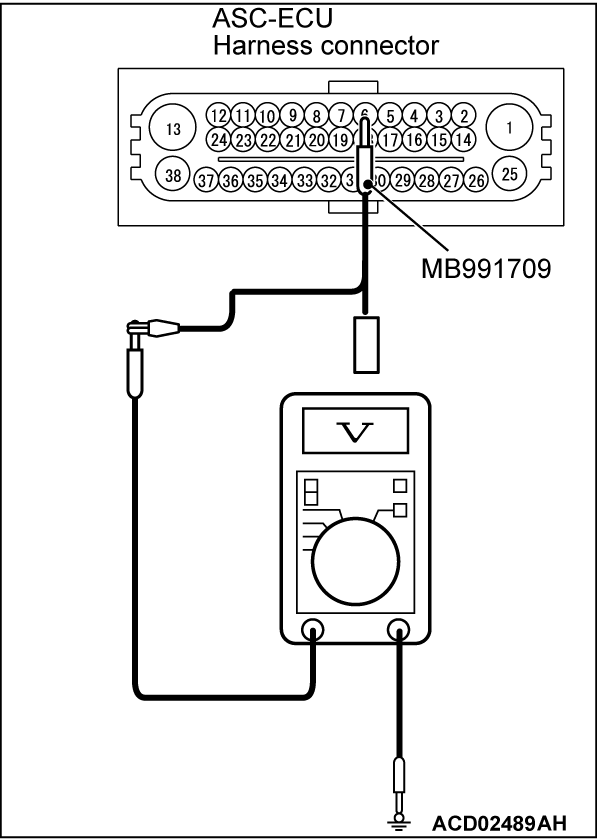

STEP 4. Voltage measurement at the A-03 ASC-ECU connector

(1) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the voltage at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(2) Measure the voltage between terminal No.25 and body ground.

OK: Approximately system voltage

Is the check result normal?

STEP 5. Fusible link check: Check the fusible link No.27.

Is the check result normal?

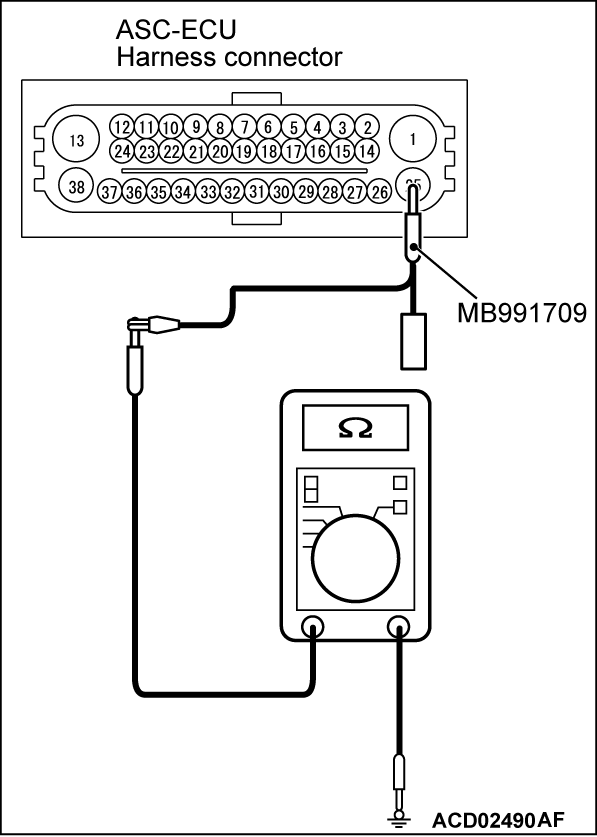

STEP 6. Resistance measurement at A-03 ASC-ECU connector

(1) Removal the fusible link No.27.

(2) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the resistance at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(3) Measure the resistance between the terminal No.25 and the body ground.

OK: No continuity

Is the check result normal?

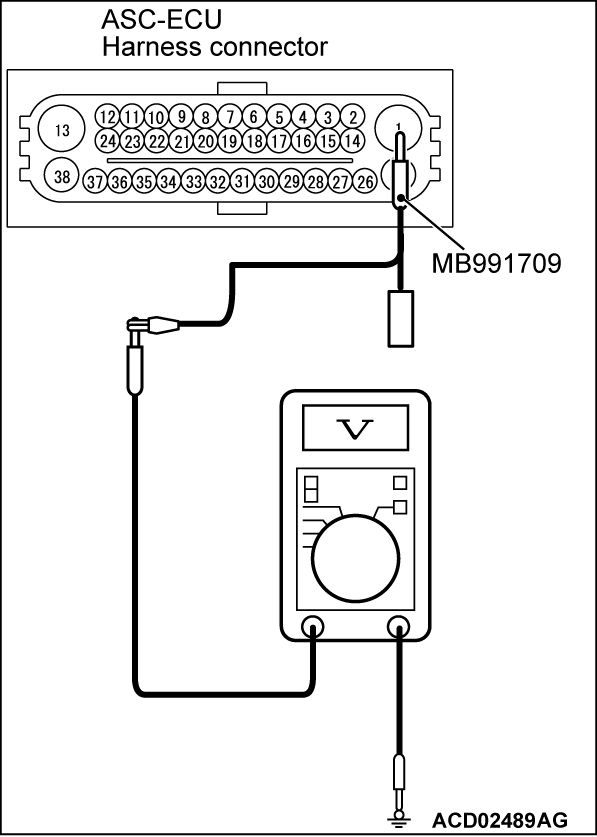

STEP 7. Voltage measurement at the A-03 ASC-ECU connector

(1) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the voltage at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(2) Measure the voltage between terminal No.1 and body ground.

OK: Approximately system voltage

Is the check result normal?

STEP 8. Check the fusible link No.26.

Is the check result normal?

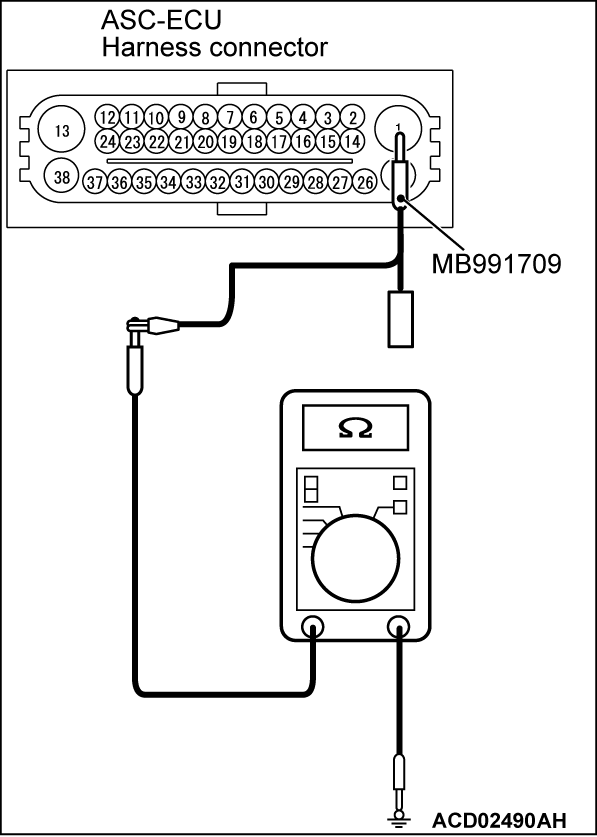

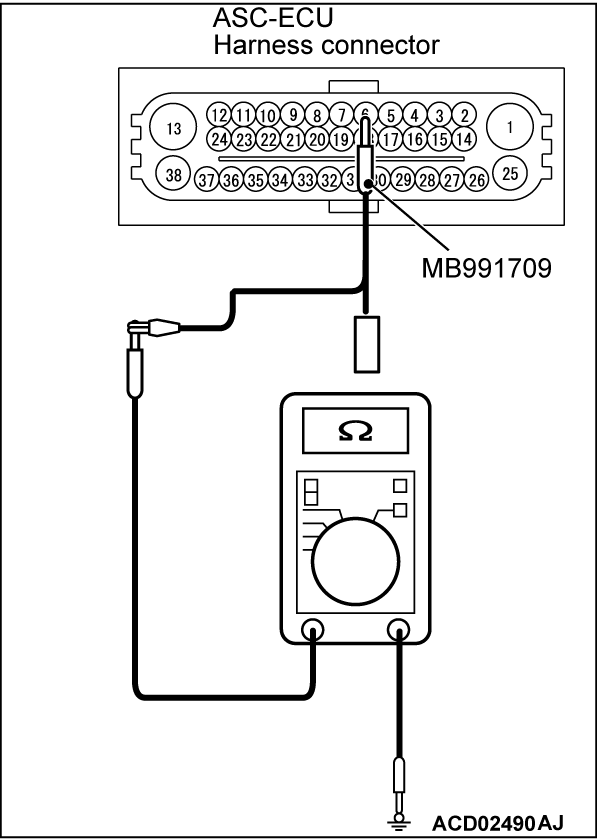

STEP 9. Resistance measurement at A-03 ASC-ECU connector

(1) Removal the fusible link No.26.

(2) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the resistance at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(3) Measure the resistance between the terminal No.1 and the body ground.

OK: No continuity

Is the check result normal?

STEP 10. Voltage measurement at the A-03 ASC-ECU connector

(1) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the voltage at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(2) Ignition switch: "ON" position.

(3) Measure the voltage between terminal No.6 and body ground.

OK: Approximately system voltage

Is the check result normal?

STEP 11. Check the fuse No.12.

Visually check for open circuit in fuse No.12.

Is the check result normal?

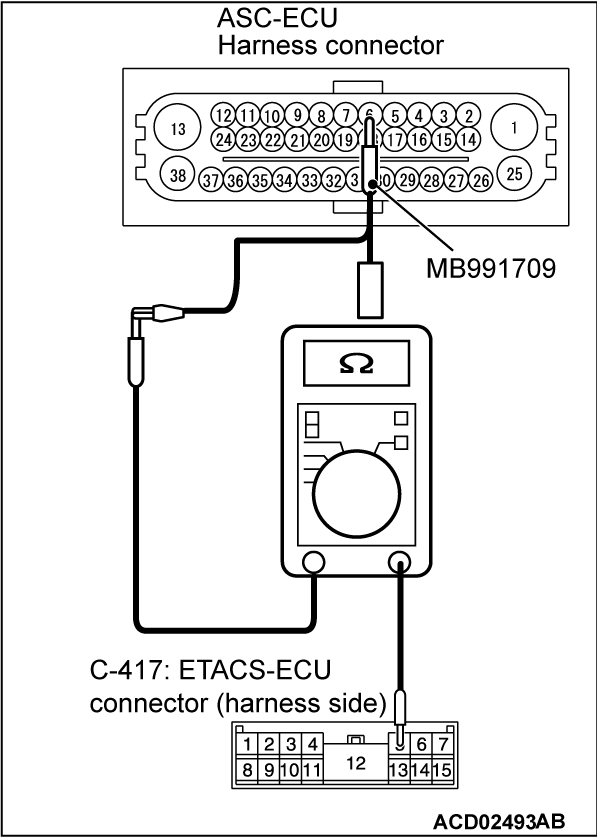

STEP 12. Resistance measurement at A-03 ASC-ECU connector

(1) Disconnect the C-417 ETACS-ECU connector.

(2) Disconnect the A-03 ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the resistance at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(3) Measure the resistance between the A-03 ASC-ECU connector terminal No.6 and the C-417 ETACS-ECU connector terminal No.5.

OK: Continuity exists (2 Ω or less)

Is the check result normal?

STEP 13. Resistance measurement at A-03 ASC-ECU connector

(1) Disconnect the C-417 ETACS-ECU connector.

(2) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the resistance at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(3) Measure the resistance between the terminal No.8 and the body ground.

OK: No continuity

Is the check result normal?

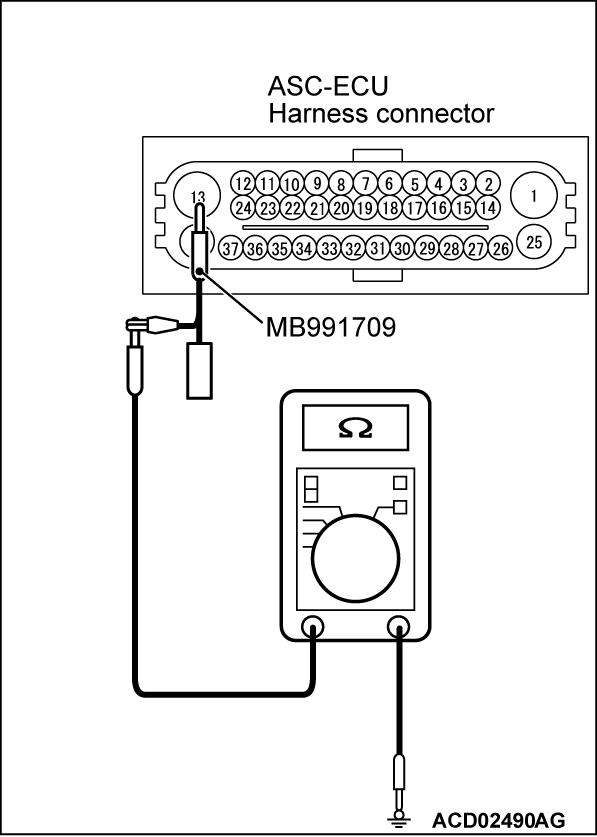

STEP 14. Resistance measurement at the A-03 ASC-ECU connector

(1) Disconnect the ASC-ECU connector, connect special tool test harness (MB991709) to the harness-side connector, and then measure the resistance at the special tool connector side.

| note | Do not connect the special tool test harness (MB991709) to ASC-ECU. |

(2) Measure the resistance between terminal No.13 and body ground, and between terminal No.38 and body ground.

OK: Continuity exists (2 Ω or less)

Is the check result normal?

An open circuit may be present in the ground circuit. Repair the wiring harness between the A-03 ASC-ECU connector terminal No.13 and the body ground, and between the A-03 ASC-ECU connector terminal No.38 and the body ground.

An open circuit may be present in the ground circuit. Repair the wiring harness between the A-03 ASC-ECU connector terminal No.13 and the body ground, and between the A-03 ASC-ECU connector terminal No.38 and the body ground.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)