DTC C1456: Wiring harness or coupling coil overcurrent failure

| caution | If there is any problem in the CAN bus lines, an incorrect DTC may be set. Prior to this diagnosis, always diagnose the CAN bus lines. |

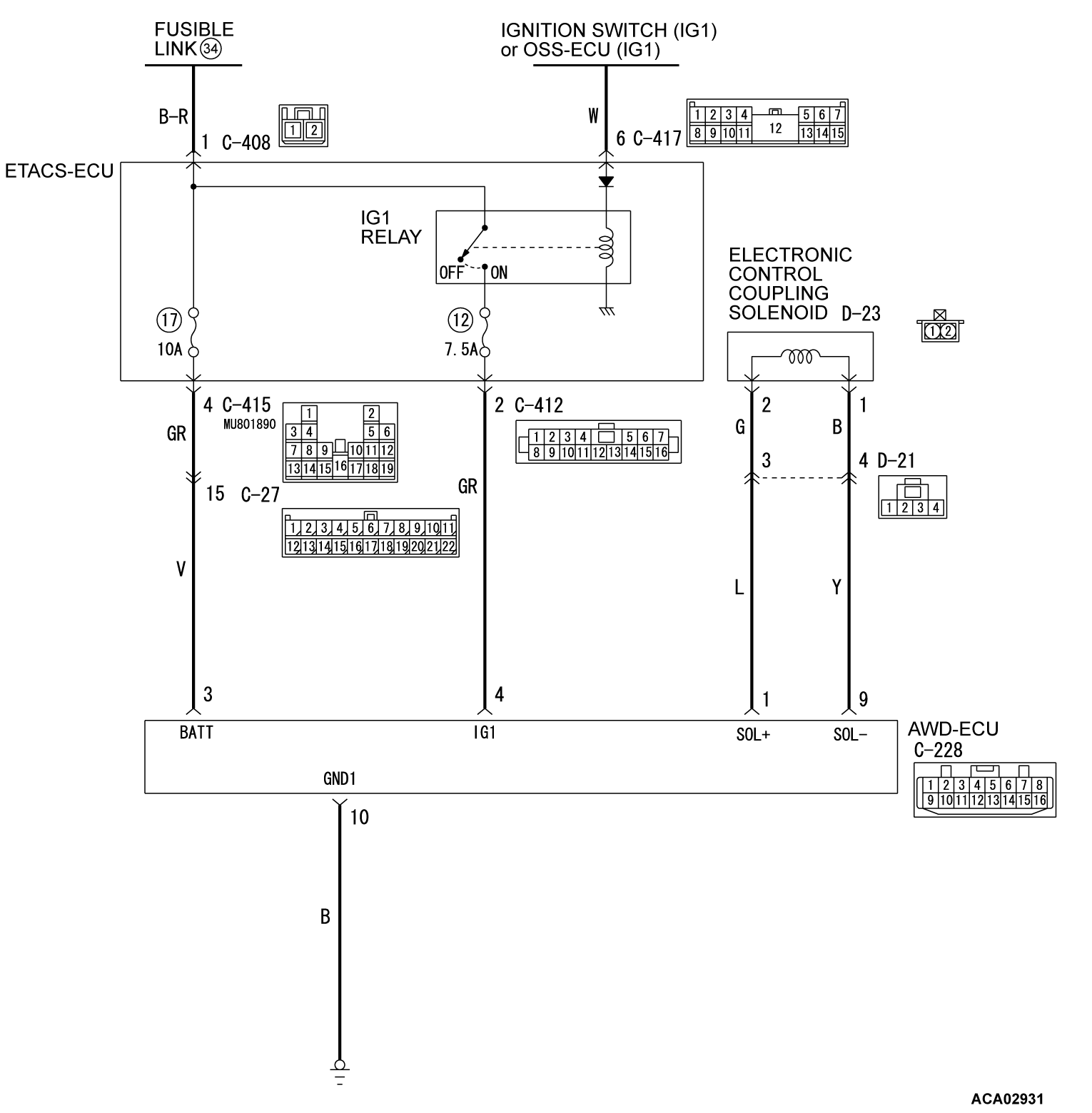

OPERATION

The current flowing the coupling coil is monitored, and if it exceeds the specified value, the system is deactivated.

DTC SET CONDITIONS

If the following conditions are met when the system is in operation (always), AWD-ECU switches the control from AWD to FWD, flashes the AWD/LOCK indicators alternately, and sets the DTC C1456.

- Electronic control coupling solenoid current monitor value: 6 A or more (deviated from the normal current value range)

TROUBLESHOOTING HINTS

Current trouble

- Damaged harness wires and connector (Short to ground between AWD-ECU and the electronic control coupling solenoid)

- AWD-ECU internal error

- Short circuit in the coupling coil

DIAGNOSIS

STEP 1. Scan tool MB991958 CAN bus diagnostics

Use scan tool MB991958 to diagnose the CAN bus lines.

Is the check result normal?

STEP 2. Check whether the DTC is reset after repairing the CAN bus line.

(1) Erase the DTC.

(2) Turn the ignition switch from the "LOCK" (OFF) position to the "ON" position.

(3) Fully depress the accelerator pedal, and maintain its position for 2 seconds.

| note | The coupling coil electronic control is also based on the accelerator pedal opening degree, thus the signal is sent to the ECU. |

(4) Check if the DTC is set.

Is the DTC C1456 set?

The procedure is complete.

The procedure is complete.STEP 3. Scan tool MB991958 data list

Check the following data list (Refer to  ).

).

).

).- Item 04: Desired current of coupling

- Item 05: Monitored current of coupling

Is the check result normal?

STEP 4. Check the following connector:

Check the connectors below for improper engagement, terminal damage or terminal drawn in the connector case.

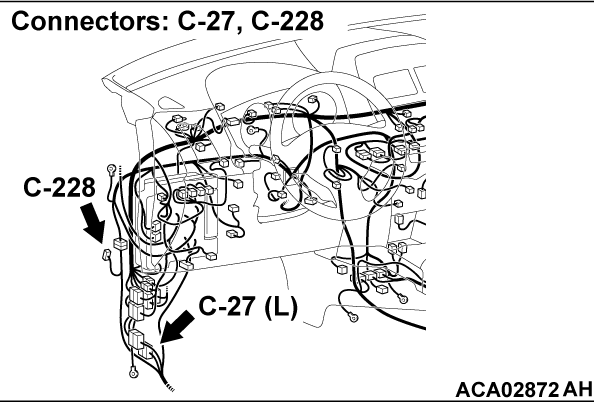

- C-228 AWD-ECU connector

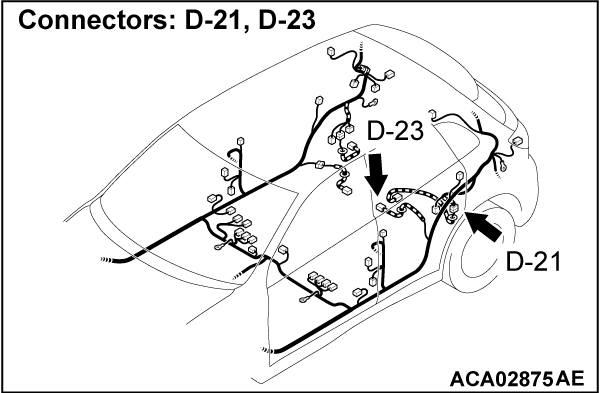

- D-21 intermediate connector

- D-23 electronic control coupling solenoid connector

- C-27 intermediate connector

Are the connectors and terminals in good condition?

STEP 5. Wiring harness check

Check the wiring harness between the C-228 AWD-ECU connector and the D-21 intermediate connector, and the wiring harness between the D-21 intermediate connector and the D-23 electronic control coupling solenoid side connector for damage or other problem.

Is the wiring harness in good condition?

STEP 6. Resistance measurement between electronic control coupling solenoid connector terminals

Disconnect the D-23 connector, and measure the resistance value between the connector terminals on the electronic control coupling side.

Standard value: 2.2 - 4.0 Ω

Is the measured resistance value within the standard value range?

STEP 7. Voltage measurement at the AWD-ECU connector

(1) Disconnect the C-228 AWD-ECU connector.

(2) Measure the voltage between the C-228 wiring harness side connector terminals No.3, No.4 (ignition switch "ON") and the body ground.

OK: System voltage

Is the check result normal?

STEP 8. Wiring harness check

Check the wiring harness between the C-228 AWD-ECU connector (terminal No.10) and the body ground for damage or other problem.

Is the wiring harness in good condition?

STEP 9. Wiring harness check

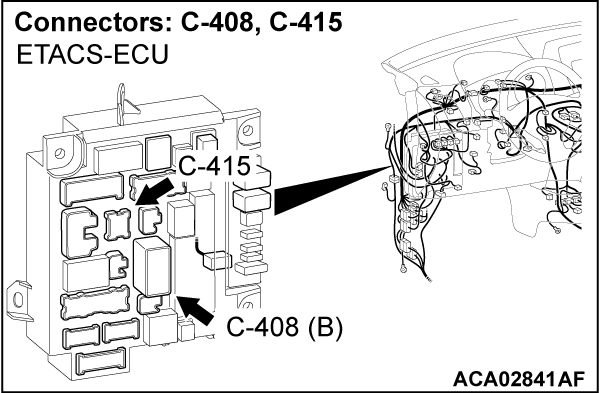

| note | Prior to the wiring harness inspection, check the C-408 and C-415 ETACS-ECU connector, and repair if necessary. |

Check the wiring harness between the C-228 AWD-ECU connector (terminal No.3) and the fusible link No. 34, and the wiring harness between the C-228 AWD-ECU connector [terminal No.4 (ignition switch "ON")] and the fusible link No. 34 for damage or other problem.

Is the wiring harness in good condition?

STEP 10. Check whether the DTC is reset.

(1) Erase the DTC.

(2) Turn the ignition switch from the "LOCK" (OFF) position to the "ON" position.

(3) Fully depress the accelerator pedal, and maintain its position for 2 seconds.

| note | The coupling coil electronic control is also based on the accelerator pedal opening degree, thus the signal is sent to the ECU. |

(4) Check if the DTC is set.

Is the DTC C1456 set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)