DTC P061A: Internal Control Module Torque Performance Problem

TECHNICAL DESCRIPTION

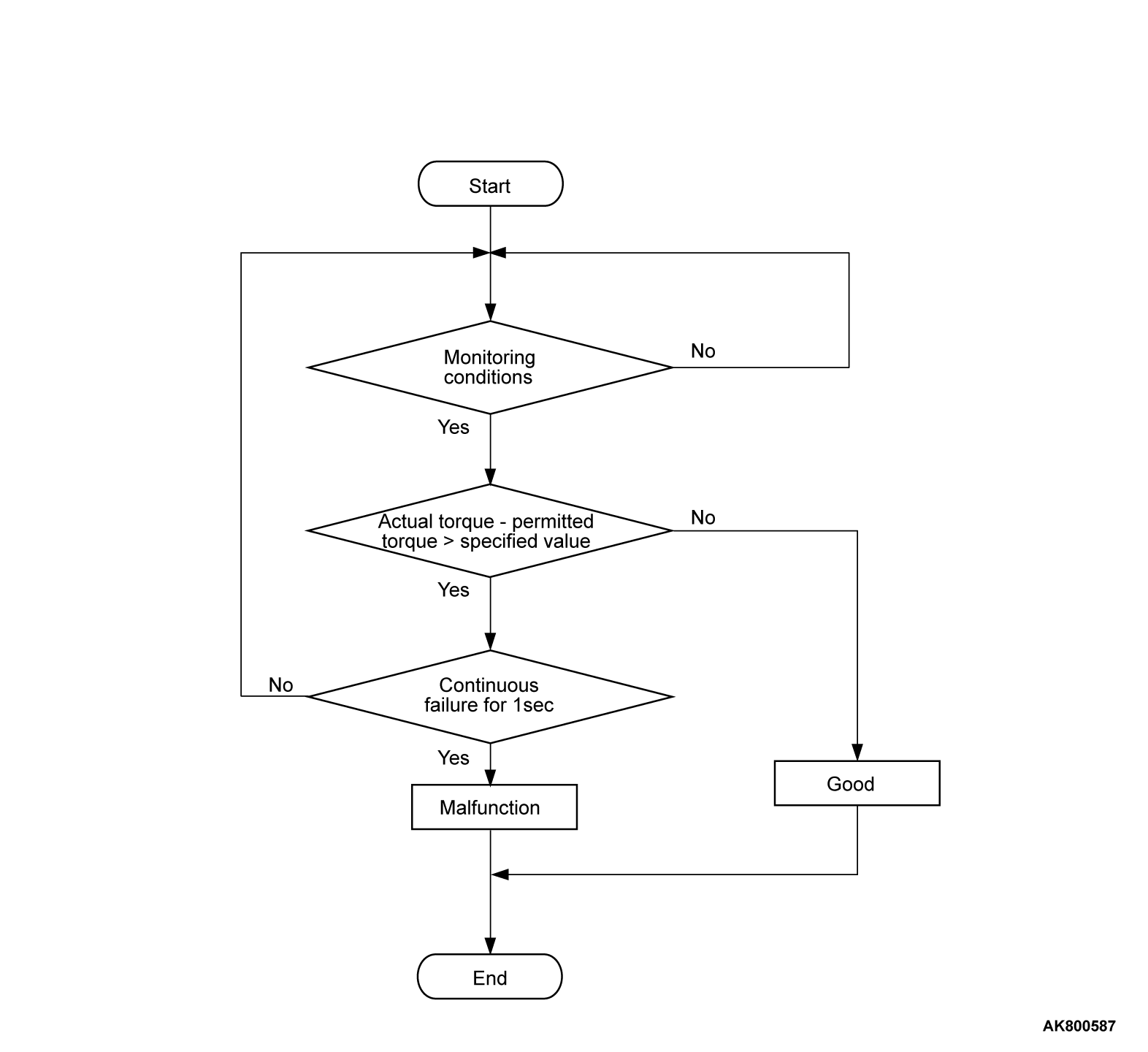

Compares the actual torque signal computed from a mass airflow sensor signal with the driver demand torque signal computed from an accelerator pedal position sensor signal.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- Engine speed is more than 500 r/min.

- Volumetric efficiency is more than 16 percent.

Judgment Criterion

- The requested torque signal subtracted from the actual torque signal is more than 50 N·m (37 ft-lb) for 5 second.

FAIL-SAFE AND BACKUP FUNCTION

- Throttle opening degree position is in default position.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Throttle actuator control motor failed.

- Connector damage.

- Harness damage.

- Intake system vacuum leak.

- There is some foreign matter around mass airflow sensor.

- ECM failed.

DIAGNOSIS

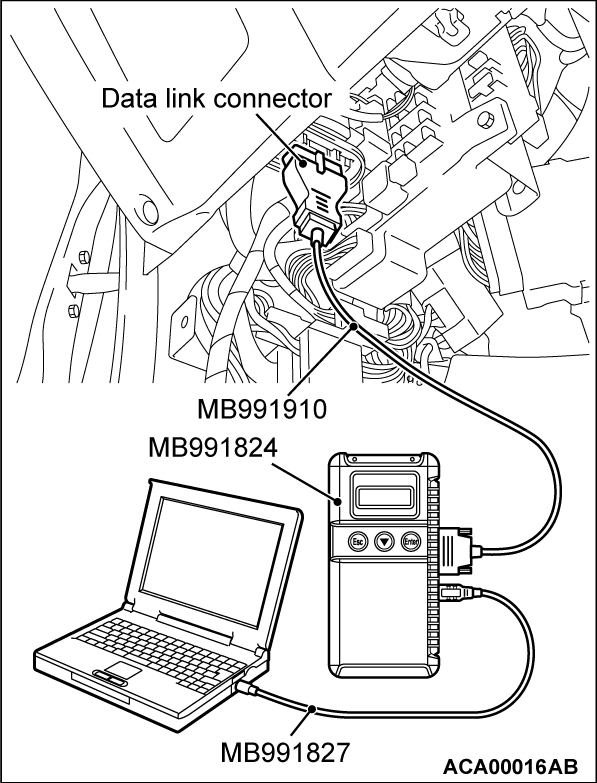

Required Special Tool:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

STEP 1. Using scan tool MB991958, read the diagnostic trouble code (DTC).

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Read the DTC.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the diagnostic trouble code other than P061A set?

STEP 2. Check for intake system vacuum leak.

STEP 3. Check for foreign matter being around the mass airflow sensor.

STEP 4. Using scan tool MB991958, check data list item 10: Mass Airflow Sensor.

(1) Start the engine and run at idle.

(2) Set scan tool MB991958 to the data reading mode for item 10, Mass Airflow Sensor.

(3) Warm up the engine to normal operating temperature: 80°C to 95°C (176°F to 203°F).

- The standard value during idling should be between 1,350 and 1,670 millivolts.

- When the engine is revved, the output voltage should increase according to the increase in engine speed.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

STEP 5. Using scan tool MB991958, check data list item 11: Accelerator Pedal Position Sensor (main).

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991958 to the data reading mode for item 11, Accelerator Pedal Position Sensor (main).

- Output voltage should be between 900 and 1,100 millivolts when foot is released from accelerator pedal.

- Output voltage should be 4,000 millivolts or more when accelerator pedal is fully depressed.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

STEP 6. Using scan tool MB991958, check data list item 12: Accelerator Pedal Position Sensor (sub).

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991958 to the data reading mode for item 12, Accelerator Pedal Position Sensor (sub).

- Output voltage should be between 400 and 600 millivolts when foot is released from accelerator pedal.

- Output voltage should be 2,000 millivolts or more when accelerator pedal is fully depressed.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

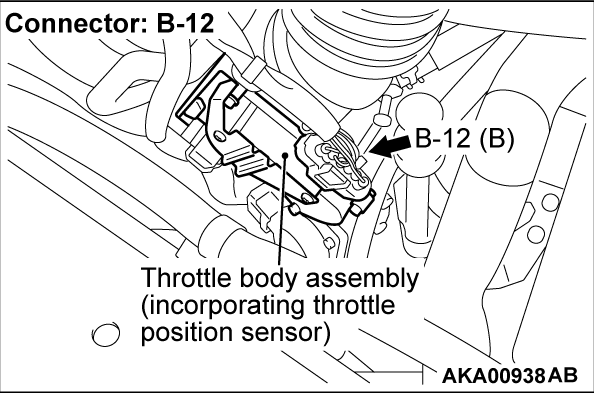

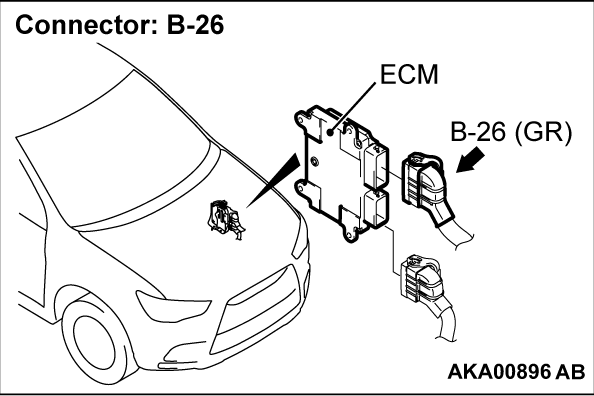

STEP 7. Check harness connector B-12 at electronic-controlled throttle valve and harness connector B-26 at ECM for damage.

Are the harness connectors in good condition?

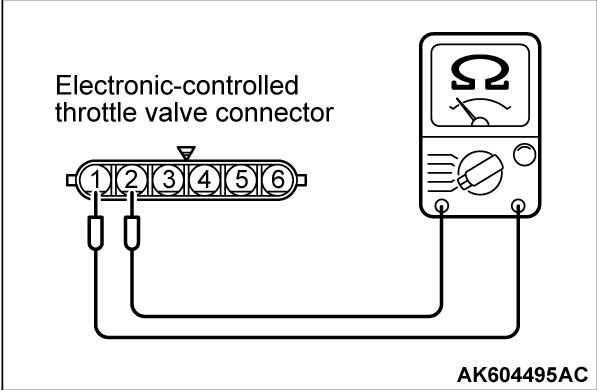

STEP 8. Check the throttle actuator control motor.

(1) Disconnect the electronic-controlled throttle valve connector B-12.

(2) Measure the resistance between electronic-controlled throttle valve side connector terminal No. 1 and No. 2.

Standard value: 0.3 - 80 Ω [at 20°C (68°C)]

Is the measured resistance between 0.3 and 80 Ω [at 20°C (68°C)?

STEP 9. Check for harness damage between electronic-controlled throttle valve connector B-12 (terminal No. 1) and ECM connector B-26 (terminal No. 15).

STEP 10. Check for harness damage between electronic-controlled throttle valve connector B-12 (terminal No. 2) and ECM connector B-26 (terminal No. 16).

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)