DTC P0D67: BATT. Charger Control Circuit Abnormal

MONITOR EXECUTION

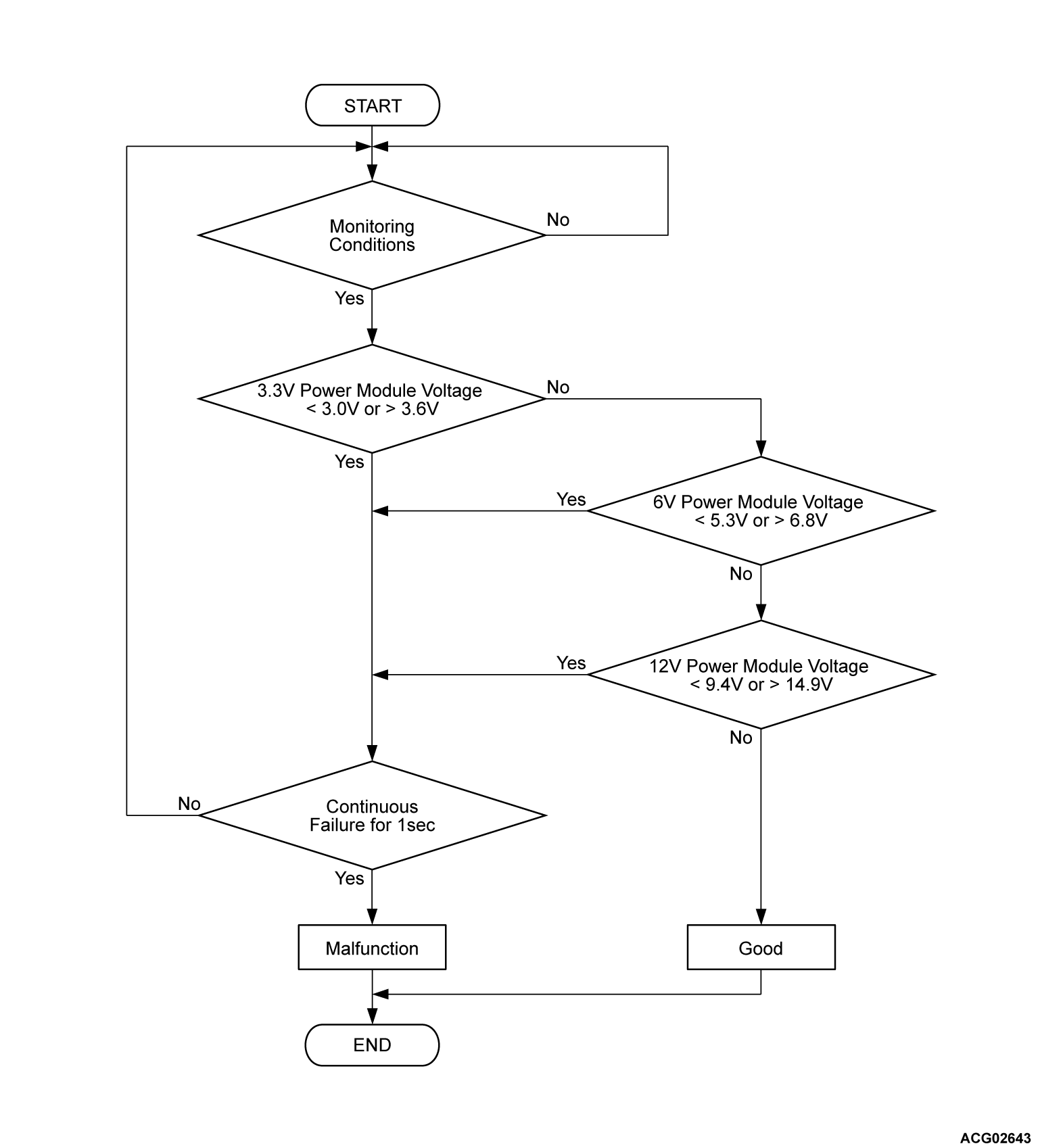

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- OBC power supply voltage is 10 volts to 16 volts.

Judgment Criterion

- Change of the 3.3 V power module voltage is less than 3 volts or more than 3.6 volts for 1 second.

- Change of the 6 V power module voltage is less than 5.3 volts or more than 6.8 volts for 1 second.

- Change of the 12 V power module voltage is less than 9.4 volts or more than 14.9 volts for 1 second.

FAIL-SAFE AND BACKUP FUNCTION

- The charge is stopped.

PROBABLE CAUSE

- The on board charger/DC-DC converter is failed.

DIAGNOSIS

STEP 1. Test the OBD-II drive cycle.

(2) Check the DTC.

Is the DTC set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)