DTC P3240, P3241, P3242, P3243, P3244, P3246, P3247, P3248, P3249, P324A, P324C, P324D, P324E, P324F, P3250, P3252, P3253, P3254, P3255, P3256, P3258, P3259, P325A, P325B, P325C, P3264, P3265, P3266, P3267, P3268, P326A, P326B, P326C, P326D, P326E, P3270, P3271, P3272, P3273, P3274, P3276, P3277, P3278, P3279, P327A, P327C, P327D, P327E, P327F, P3280: Module High Temperature

| caution | Before replacing the ECU, ensure that the communication circuit is normal. |

MONITOR EXECUTION

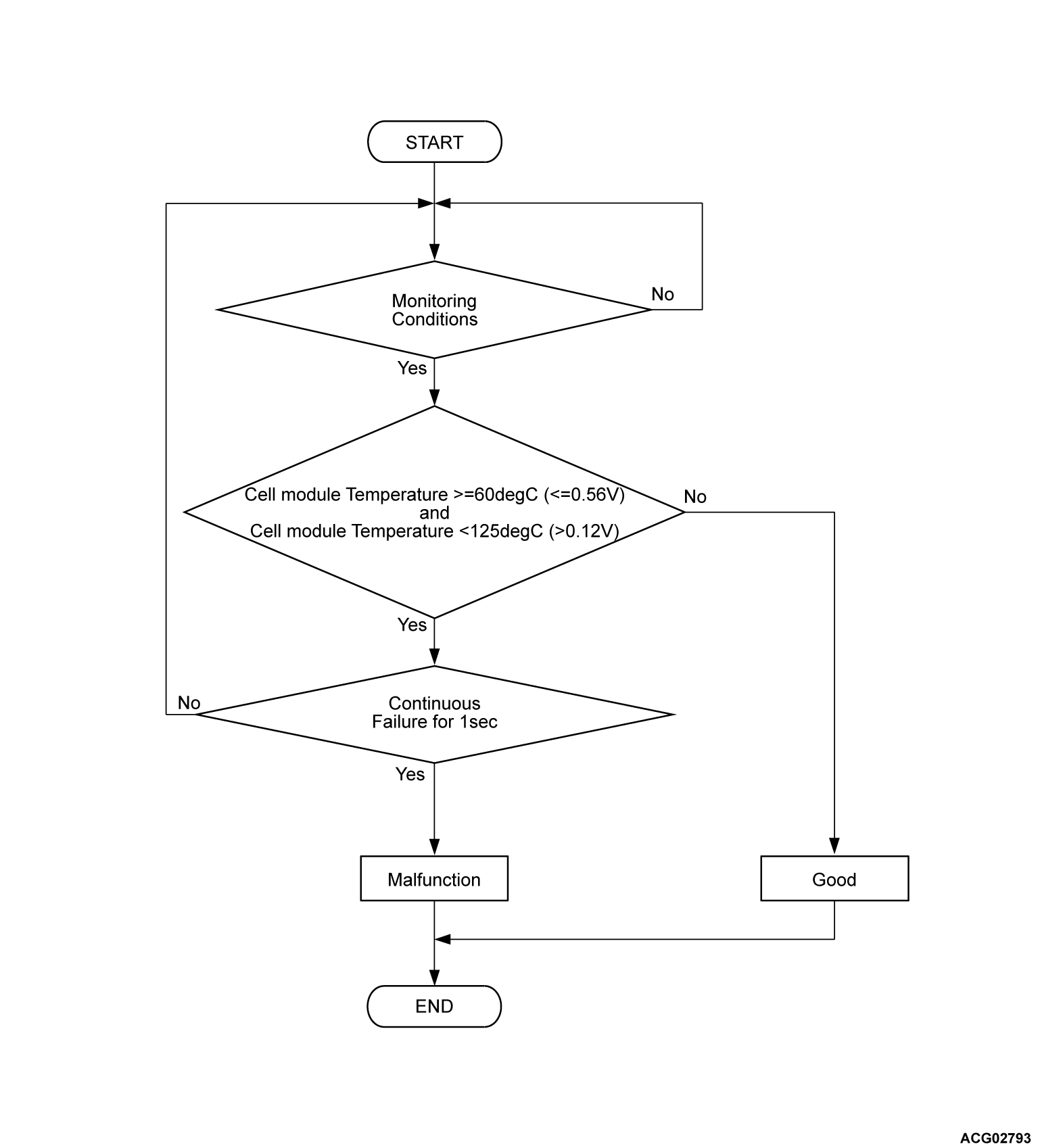

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Battery CAN monitor

Sensor (The sensor below is determined to be normal)

- Main drive lithium-ion battery temperature sensor monitor

DTC SET CONDITIONS

Check Conditions

- battery management unit (BMU) power supply voltage is 8 volts to 16 volts.

- Time after above conditions satisfy is more than 2 seconds.

Judgment Criterion

- Cell module temperature is 60°C (140°F) or more and less than 125°C (257°F) and the state continues for 1 second.

FAIL-SAFE AND BACKUP FUNCTION

- Not available

PROBABLE CAUSES

- The main drive lithium-ion battery cooling is insufficient with the failed air conditioning control system.

- Poor cooled main battery due to a defective battery cooling fan.

- The module (battery cell, CMU) in the main drive lithium-ion battery is failed.

DIAGNOSIS

STEP 1. Using scan tool (M.U.T.-IIISE), check whether the other DTC is set.

Check whether DTC P0A82, P0A83 and P0A84 are set at the same time.

Is the DTC set?

STEP 2. Using scan tool (M.U.T.-IIISE), check whether the other DTC is set.

Is the DTC related to A/C-ECU or A/C compressor assembly system set?

STEP 3. Using scan tool (M.U.T.-IIISE), check the data list.

Set scan tool (M.U.T.-IIISE) to the data list (Refer to  ).

).

).

).- Item No.177 - 181: Module temperature 00 - 04

- Item No.183 - 187: Module temperature 06 - 10

- Item No.189 - 193: Module temperature 12 - 16

- Item No.195 - 199: Module temperature 18 - 22

- Item No.201 - 205: Module temperature 24 - 28

- Item No.213 - 217: Module temperature 36 - 39

- Item No.219 - 223: Module temperature 42 - 46

- Item No.225 - 229: Module temperature 48 - 52

- Item No.231 - 235: Module temperature 54 -58

- Item No.237 - 241: Module temperature 60 -64

OK: At ambient temperature (atmospheric temperature) or equivalent (when the vehicle driving and the charge are not performed for a long time)

Is the check result normal?

STEP 4. Check the bus bar for looseness.

(2) Check the bus bar around the module of the set diagnostic trouble code for looseness.

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)