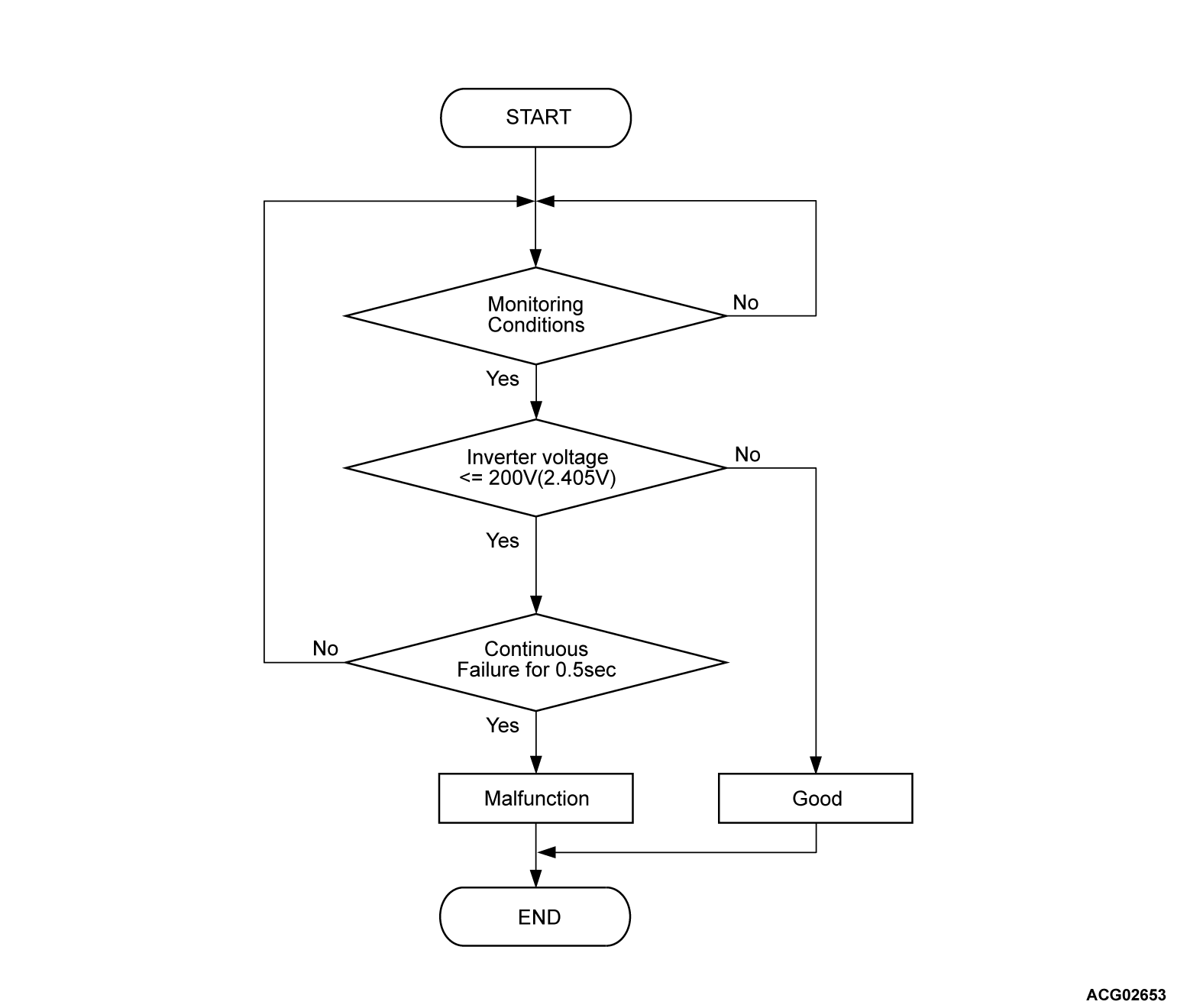

DTC P1037: Electric motor drive voltage too low

| danger |

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Drive motor inverter voltage sensor

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- The vehicle status is propulsion system active.

Judgment Criterion

- Change of the inverter voltage is less than 200 volts (2.405 volts) for 0.5 second.

PROBABLE CAUSES

- The battery pack fails

- The high-voltage circuit fails

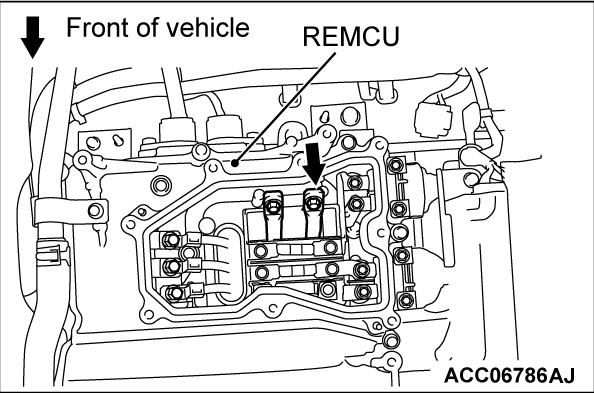

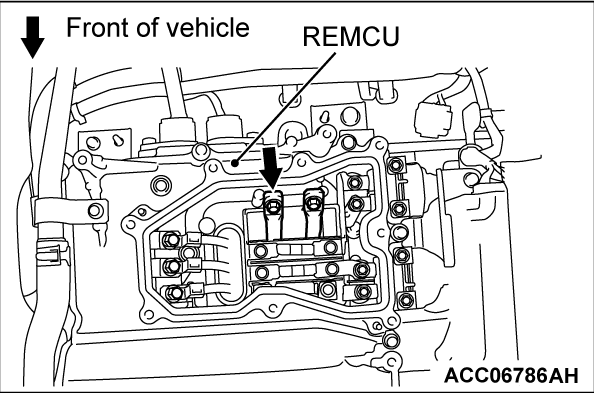

- Malfunction of the REMCU

DIAGNOSIS

Required Special Tools

- MB991223: Wiring harness set

- MB992006: Extra fine probe

STEP 1. Using scan tool (M.U.T.-IIISE), check whether the other DTC is set.

Check if DTC P1A1B is set in the power drive unit (FEMCU), and if DTC P104D is set in the power drive unit [generator control unit (GCU)].

Is the DTC set?

STEP 2. Check the high-voltage fuse.

| danger |

|

Is the check result normal?

STEP 3. Check the high-voltage circuit.

| danger |

|

Check whether the high-voltage wiring harness is connect securely or damaged.

Is the check result normal?

STEP 4. Check the high-voltage circuit.

| danger |

|

(2) Apply a voltage of 12 V to the CNT- terminal to turn on the charging contactor.

(3) Connect a high-voltage compatible multimeter between the main drive lithium-ion battery high-voltage terminal (REMCU) and the main drive lithium-ion battery service plug rear terminal.

OK: Approximately 100 - 164 V

(4) Apply a voltage of 12 V to the CNTP terminal to turn on the charging contactor.

(5) Connect a high-voltage compatible multimeter between the main drive lithium-ion battery high-voltage terminal (REMCU) and the main drive lithium-ion battery service plug front terminal.

OK: Approximately 100 - 164 V

(6) Apply a voltage of 12 V to the CNT+ terminal to turn on the charging contactor.

(7) Connect a high-voltage compatible multimeter between the main drive lithium-ion battery high-voltage terminal (REMCU) and the main drive lithium-ion battery service plug front terminal.

OK: Approximately 100 - 164 V

Is the check result normal?

STEP 5. Check the high-voltage wiring harness and bus bar in the main drive lithium-ion battery.

(1) Remove the battery tray cover (Refer to GROUP 54Dc - Main Drive Lithium-ion Battery Disassembly and Assembly  ).

).

).

).(2) Check the high-voltage wiring harness and bus bar in the main drive lithium-ion battery for looseness or damage.

Is the check result normal?

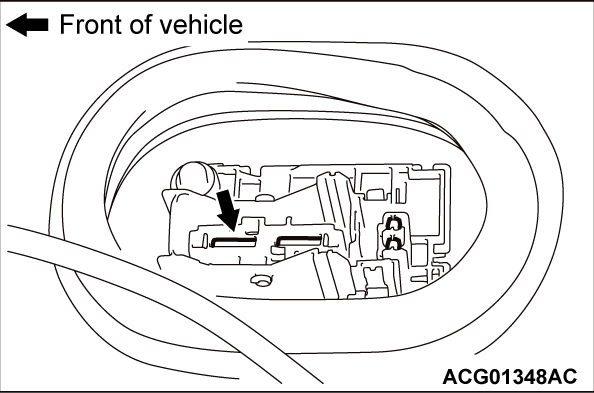

STEP 6. Check the high-voltage terminal.

| danger |

|

Check that the following cable is tightened to the specified torque.

Is the check result normal?

STEP 7. Check the high-voltage circuit.

| danger |

|

(1) Check that the following cable is tightened to the specified torque.

(2) Check if the main drive lithium-ion battery rear cable (P, N line) is damaged.

Is the check result normal?

STEP 8. Test the OBD-II drive cycle.

(2) Check the DTC.

Is the DTC set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)