DTC U0141: CAN time-out error (ETACS)

DIAGNOSTIC FUNCTION

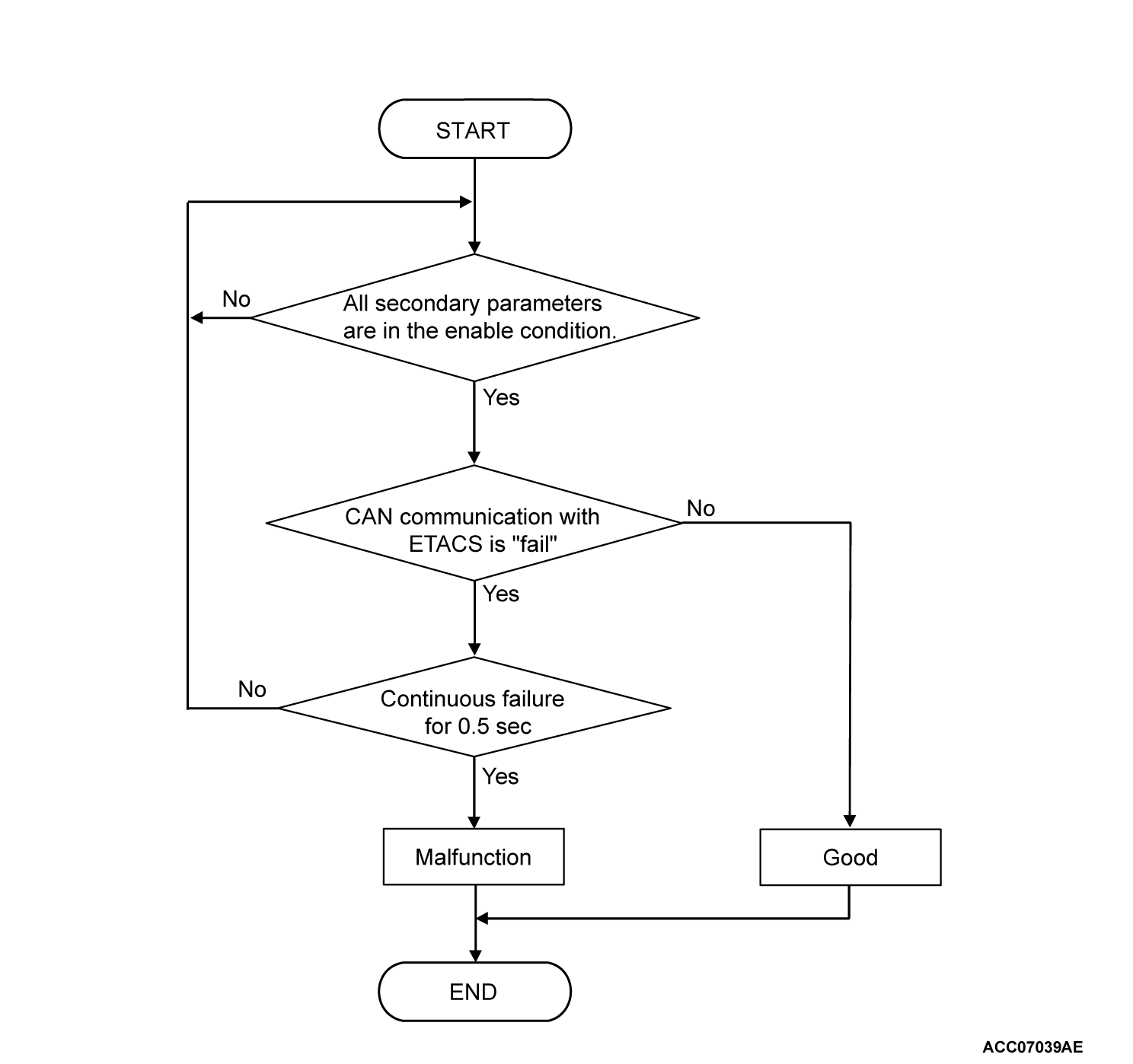

The TCM determines that the system is defective if the TCM can receive no CAN communication information from the ETACS-ECU.

DESCRIPTIONS OF MONITOR METHODS

No information is received from the ETACS-ECU for 0.5 seconds.

MONITOR EXECUTION

- When 1.05 seconds have elapsed after TCM started

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0712, P0713: Malfunction of the transmission fluid temperature sensor

- P0715: Malfunction of primary pulley speed sensor

- P0720: Malfunction of secondary pulley speed sensor

- P0730: Incorrect gear ratio

- P0966, P0967: Malfunction of secondary pressure solenoid valve

- P0970, P0971: Malfunction of primary pressure solenoid valve

- P2720, P2721: Malfunction of select pressure solenoid valve

- P2763, P2764: Malfunction of lock-up solenoid valve

- P2765: Malfunction of turbine speed sensor

Sensor (The sensor below is determined to be normal)

- Transmission fluid temperature sensor

- Primary pulley speed sensor

- Secondary pulley speed sensor

- Turbine speed sensor

DTC SET CONDITIONS

Check Conditions

- Voltage of battery: 10 volts or more

- Time after TCM start: More than 1.05 seconds.

Judgment Criteria

- CAN communication with ETACS-ECU: fail. (0.5 second)

OBD-II DRIVE CYCLE PATTERN

Ignition switch: ON (start the engine and keep it for 10 seconds or more)

PROBABLE CAUSES

- Malfunction of the CAN bus line

- Malfunction of ETACS-ECU

- Malfunction of TCM

DIAGNOSIS

STEP 1. M.U.T.-III CAN bus diagnostics

Use scan tool to perform the CAN bus diagnosis.

Is the check result normal?

STEP 2. M.U.T.-III diagnostic trouble code

Check if the ETACS-related diagnostic trouble code is set. Carry out the appropriate troubleshooting.

Carry out the appropriate troubleshooting.

Is the ETACS-related diagnostic trouble code set?

Carry out the appropriate troubleshooting.

Carry out the appropriate troubleshooting.STEP 3. M.U.T.-III diagnostic trouble code

Is diagnostic trouble code No. U0141 set in the other ECU, which communicates with the ETACS-ECU via CAN?

Is the diagnostic trouble code set?

STEP 4. Symptom recheck after erasing diagnostic trouble code

Is the diagnostic trouble code set?

Replace ETACS-ECU.

Replace ETACS-ECU.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)