HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

Most intermittent malfunctions occur under certain conditions. If those conditions can be identified, the cause will be easier to find.

TO COPE WITH INTERMITTENT MALFUNCTION;

1. ASK THE CUSTOMER ABOUT THE MALFUNCTION

1. ASK THE CUSTOMER ABOUT THE MALFUNCTION

Ask what it feels like, what it sounds like, etc. Then ask about driving conditions, weather, frequency of occurrence, and so on.

2. DETERMINE THE CONDITIONS FROM THE CUSTOMER'S RESPONSES

Typically, almost all intermittent malfunctions occur from conditions like vibration, temperature and/or moisture change, poor connections. From the customer's responses, it should be reasoned which condition is most likely.

3. USE SIMULATION TEST

Use the simulation tests below to attempt to duplicate the customer's complaint. Determine the most likely circuit(s) and perform the simulation tests on the connectors and parts of that circuit(s). Be sure to use the inspection procedures provided for diagnostic trouble codes and trouble symptoms.

For temperature and/or moisture condition related intermittent malfunctions, try to change the conditions of the suspected circuit components, then use the simulation tests below.

4. VERIFY THE INTERMITTENT MALFUNCTION IS ELIMINATED

Repair the malfunctioning part and try to duplicate the condition(s) again to verify the intermittent malfunction has been eliminated.

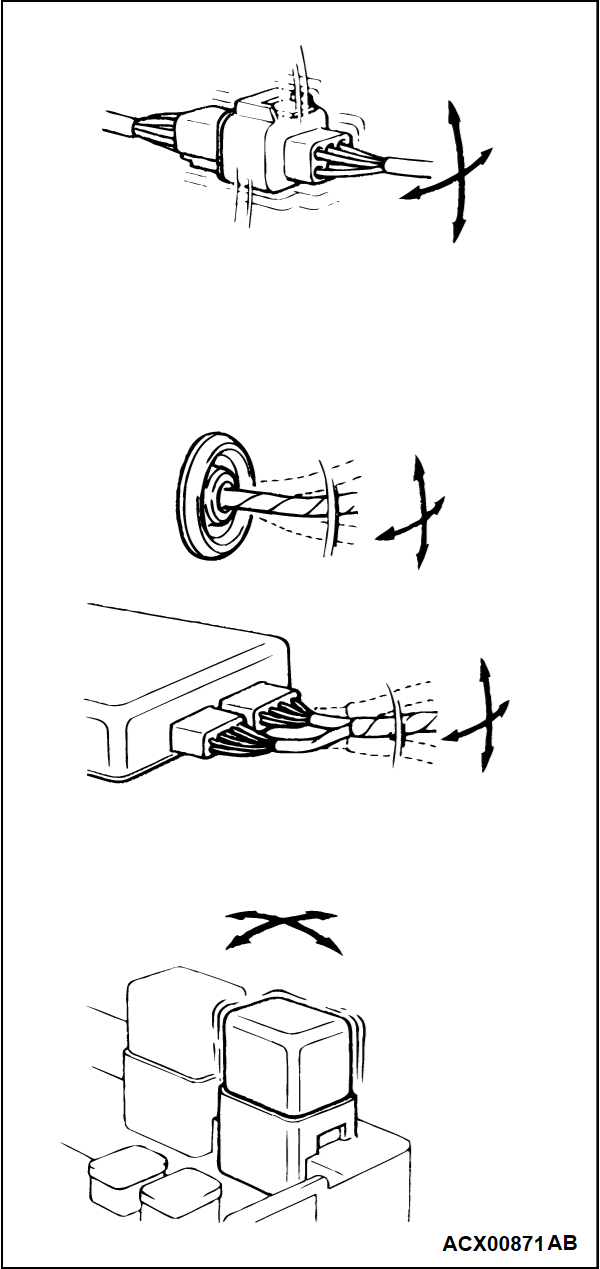

SIMULATION TESTS

| note | In case of difficulty in finding the cause of the intermittent malfunction, the data recorder function in the scan tool is effective. |

For these simulation tests, shake, then gently bend, pull, and twist the wiring of each of these examples to duplicate the intermittent malfunction.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)