HARNESS CONNECTOR INSPECTION

CONNECTOR CONTINUITY AND VOLTAGE TEST

Required Special Tools:

- MB991219: Test Harness Set

- MD998459: Test Harness

Follow the steps below to avoid causing poor connector contact and/or reduced waterproof performance of connectors when checking continuity and/or voltage at waterproof connectors.

| caution | Never backprobe a waterproof connector. Backprobing a connector may cause the terminals to corrode, deteriorating circuit performance. |

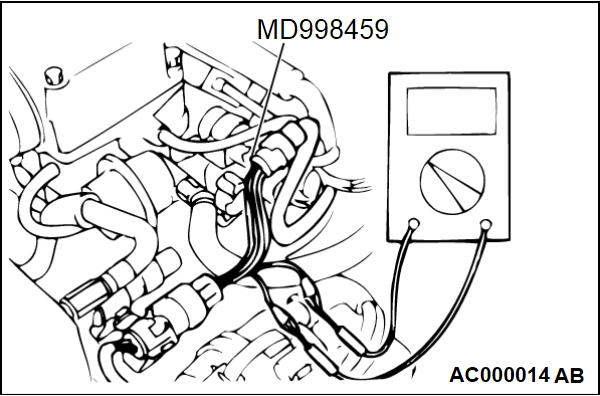

1. If the circuit to be checked is a closed state, use a special tool like MD998459.

| caution | Forcing the probe into the terminal may open the terminal, causing intermittent or poor contact and creating an open circuit. |

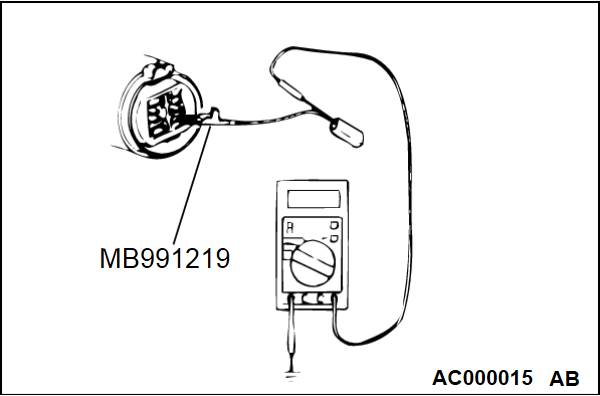

2. If the connector is disconnected for checking and the facing part is the female pin side, use an appropriate male terminal for checking the contact pressure of connector pins (like MB991219).

| caution | Do not simultaneously contact more than one terminal with the probe. Contacting two or more terminals at the same time may damage a circuit, possibly to the point of starting an electrical fire. |

3. If the facing part is the male pin side, either carefully touch the probe to the pin so it does not accidently contact other pins, or use an appropriate female terminal.

IMPROPER TERMINAL ENGAGEMENT CHECK

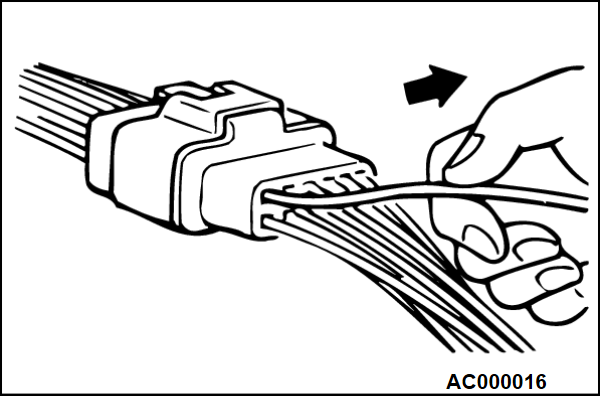

Terminals inside a connector may not engage properly even if the connectors engage. Make sure that each terminal does not come out of the connector when gently pulling each harness wire. If it does, repair or replace the terminal and/or connector.

CONNECTOR TERMINAL ENGAGEMENT AND DISENGAGEMENT

Loosely engaged terminals can be repaired by removing the female terminal from the connector housing and raising its lance to establish better engagement. Removal of the connector terminal used for MFI and INVECS-II A/T control circuit can be done in the following manner.

COMPUTER CONNECTOR

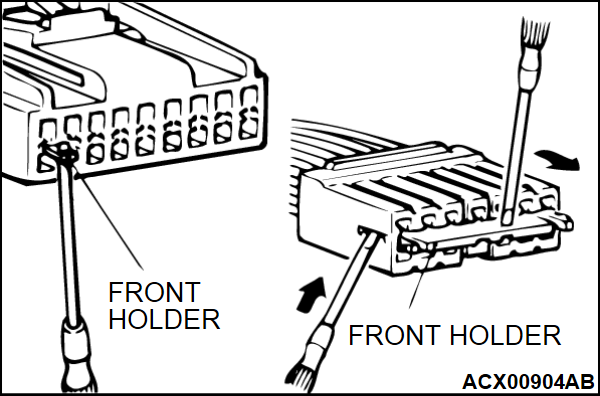

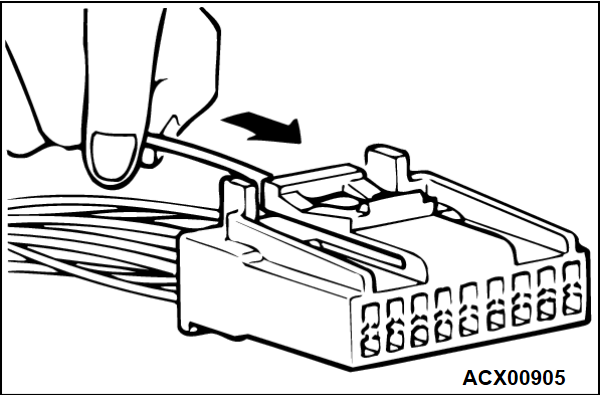

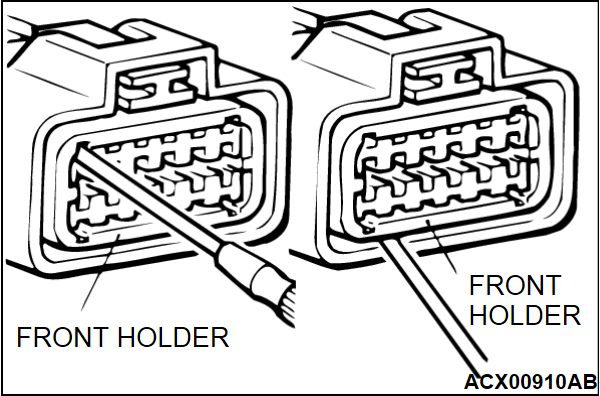

1. Insert a screwdriver [1.4 mm (0.06 inch) width] as shown in the figure, disengage the front holder, and remove it.

2. Push the harness wire of the terminal to be repaired deep into the connector from the harness side and hold it there.

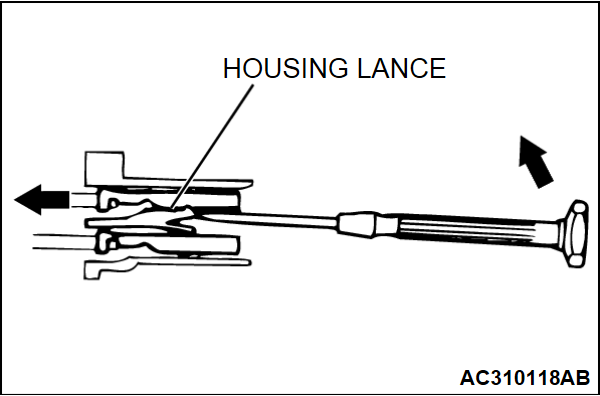

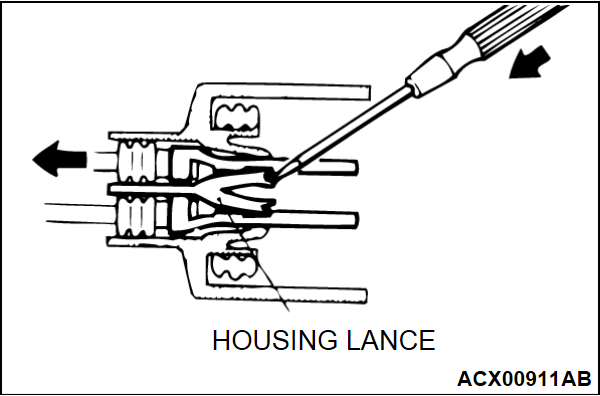

3. Insert the tip of the screwdriver [1.4 mm (0.06 inch) width] into the connector as shown in the figure, gently push the housing lance down with the tip, and pull out the terminal.

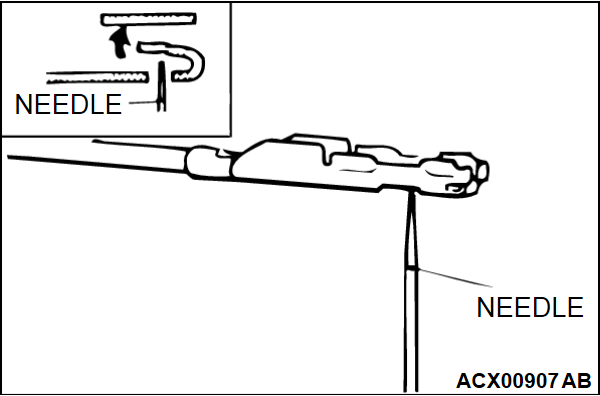

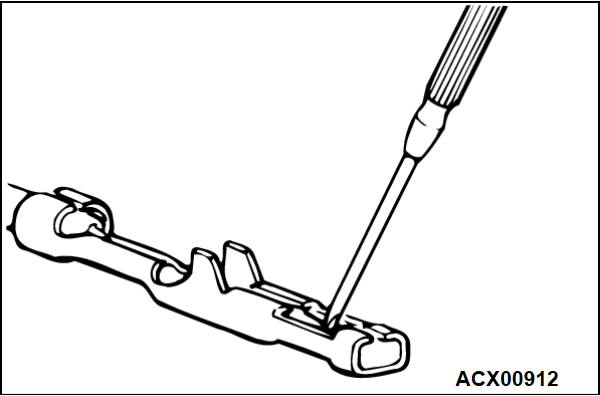

4. Insert a needle through the hole provided on the terminal and raise the contact point. Lightly squeeze the outer edge so the flats are parallel with the bottom.

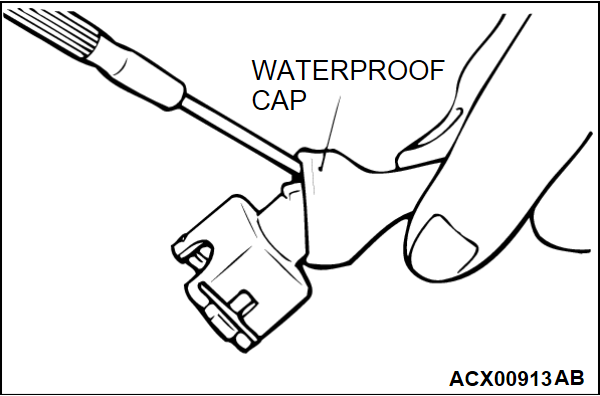

ROUND WATERPROOF CONNECTOR

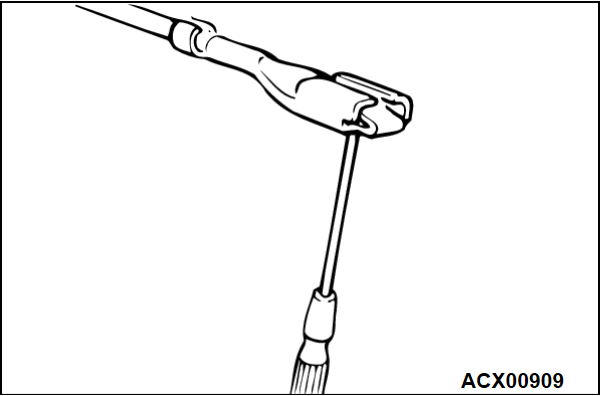

1. Remove the waterproof cap by using a screwdriver.

2. Insert the tip of the screwdriver [1.4 mm (0.06 inch) or 2.0 mm (0.08 inch) width] into the connector as shown in the figure, raise the housing lance slightly with the tip, and pull out the terminal.

3. Insert a screwdriver through the hole provided on the terminal and raise the contact point. Lightly squeeze the outer edge so the flats are parallel with the bottom.

RECTANGULAR WATERPROOF CONNECTOR

1. Disengage the front holder with a screwdriver and remove it.

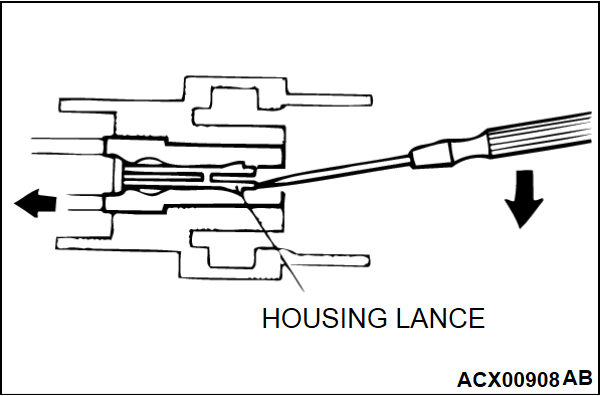

2. Insert the tip of a screwdriver [0.8 mm (0.03 inch) width] into the connector as shown in the figure, push it lightly to raise the housing lance, and pull out the terminal.

3. Press the contact point to the male terminal down by holding a screwdriver [1.4 mm (0.06 inch) width] as shown in the figure. Lightly squeeze the outer edge so the flats are parallel with the bottom.

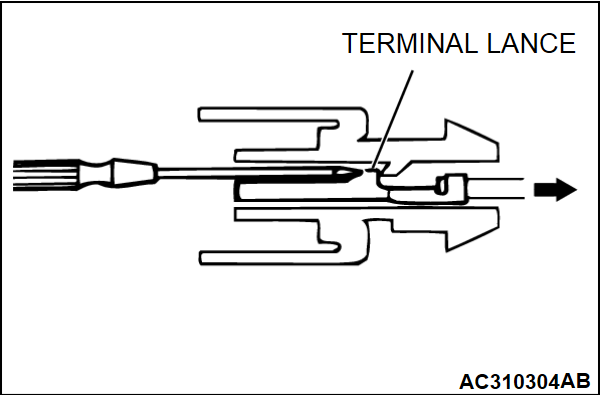

INJECTOR CONNECTOR

1. Remove the waterproof cap.

2. Insert the tip of a screwdriver [1.4 mm (0.06 inch) width] into the connector as shown in the figure, press in the terminal lance, and pull out the terminal.

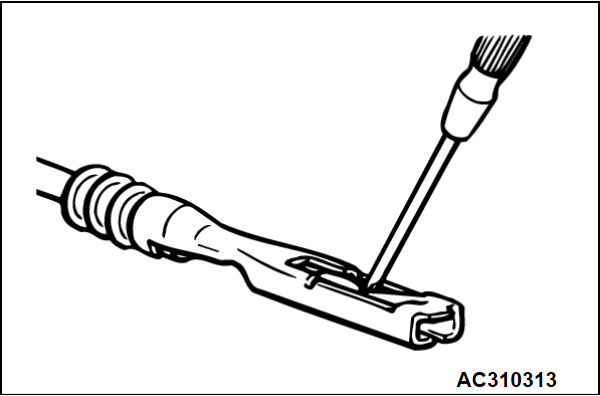

3.

Press the contact point to the male terminal down by holding a screwdriver [1.4 mm (0.06 inch) width] as shown in the figure.

| caution | Make sure the lance is pressed in before the terminal is inserted into the connector. |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)