DTC P0715: Malfunction of Primary Pulley Speed Sensor

DIAGNOSTIC FUNCTION

The TCM determines whether the system is defective by monitoring the primary pulley speed sensor.

DESCRIPTIONS OF MONITOR METHODS

- The status with the secondary pulley speed of 500 r/min or more and with the primary pulley speed of less than 150 r/min continues for 5 seconds.

- 0.5 seconds after the primary pulley speed has dropped abruptly from 1,000 r/min or more to 200 r/min or less

- Primary pulley speed is found abnormal by comparing the engine speed and the turbine speed.

MONITOR EXECUTION

- Transmission range: D

- Engine speed: 450 r/min or more

- Voltage of battery: 10 volts or more.

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0720: Malfunction of secondary pulley speed sensor

- P0730: Incorrect gear ratio

- P084A: Abnormality in primary pressure sensor function

- P2720, P2721: Malfunction of select pressure solenoid valve

- P2765: Malfunction of turbine speed sensor

Sensor (The sensor below is determined to be normal)

- Secondary pulley speed sensor

- Primary pressure sensor

- Turbine speed sensor

DTC SET CONDITIONS

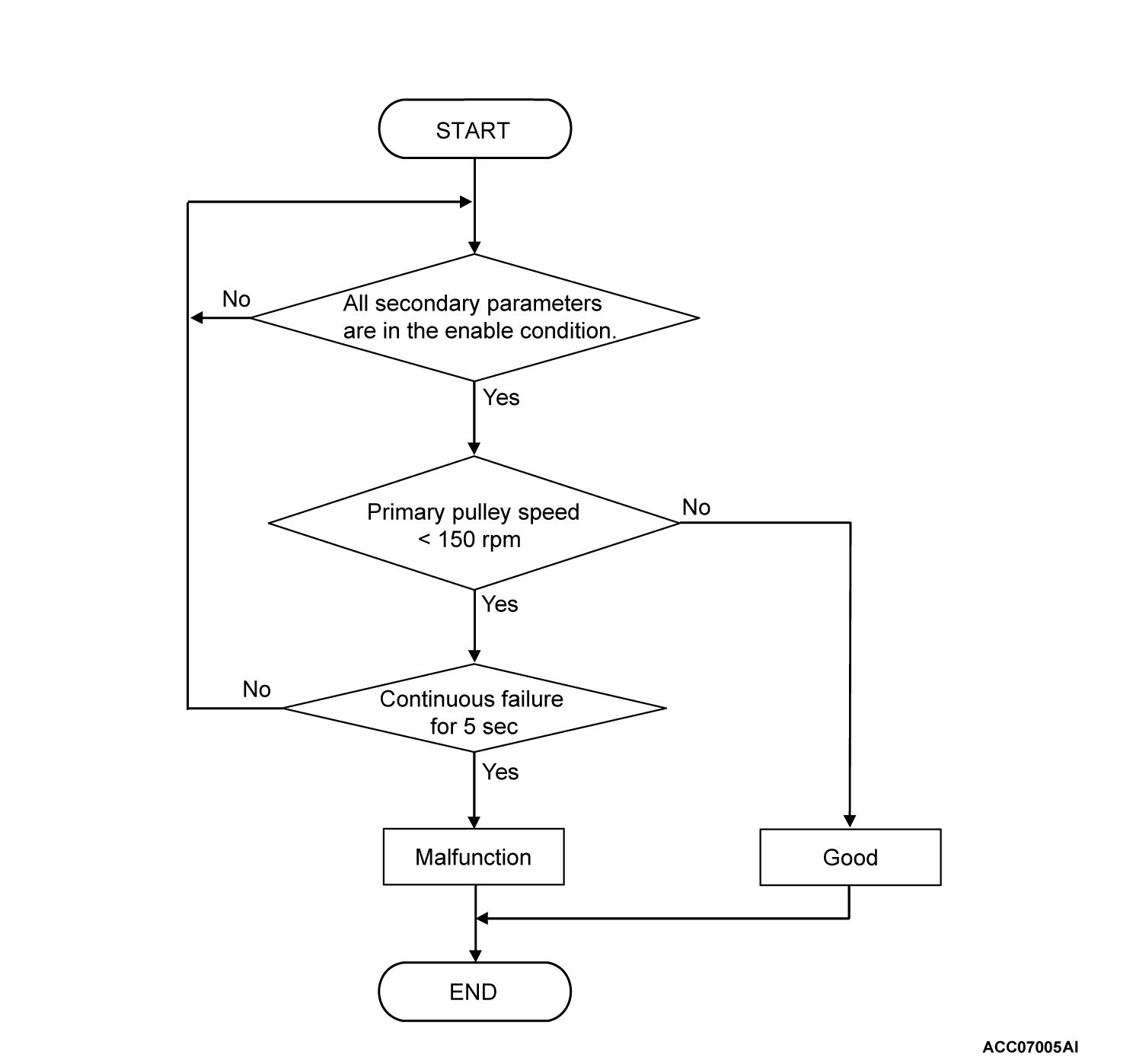

Check Conditions <Input Rationality-Low (Open/Low revolution)>

- Voltage of battery: 10 volts or more.

- Secondary pulley speed: 500 r/min or more.

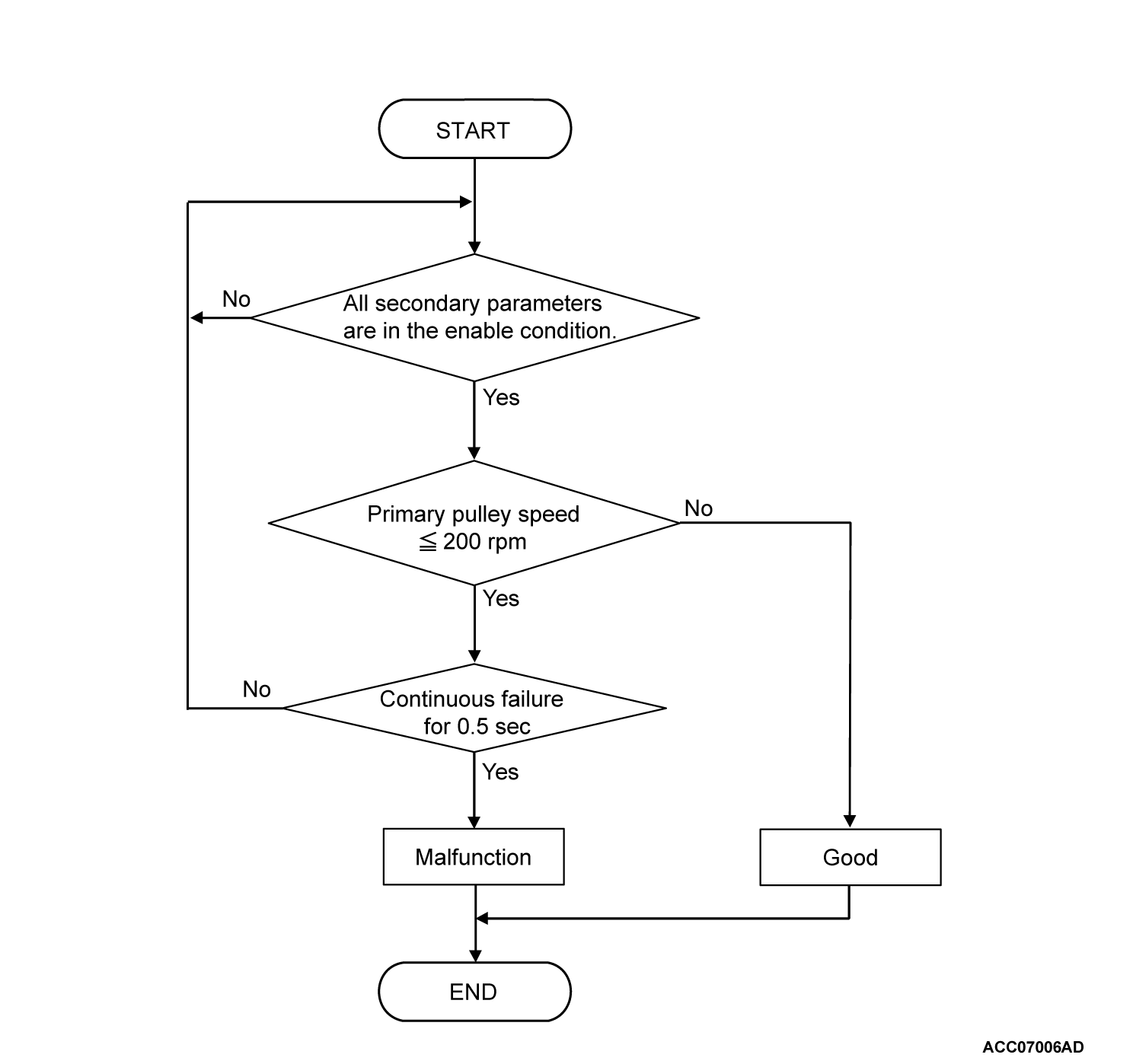

Check Conditions <Input Open Circuit>

- Voltage of battery: 10 volts or more.

- Primary pulley speed at 10 millisecond before: 1,000 r/min or more.

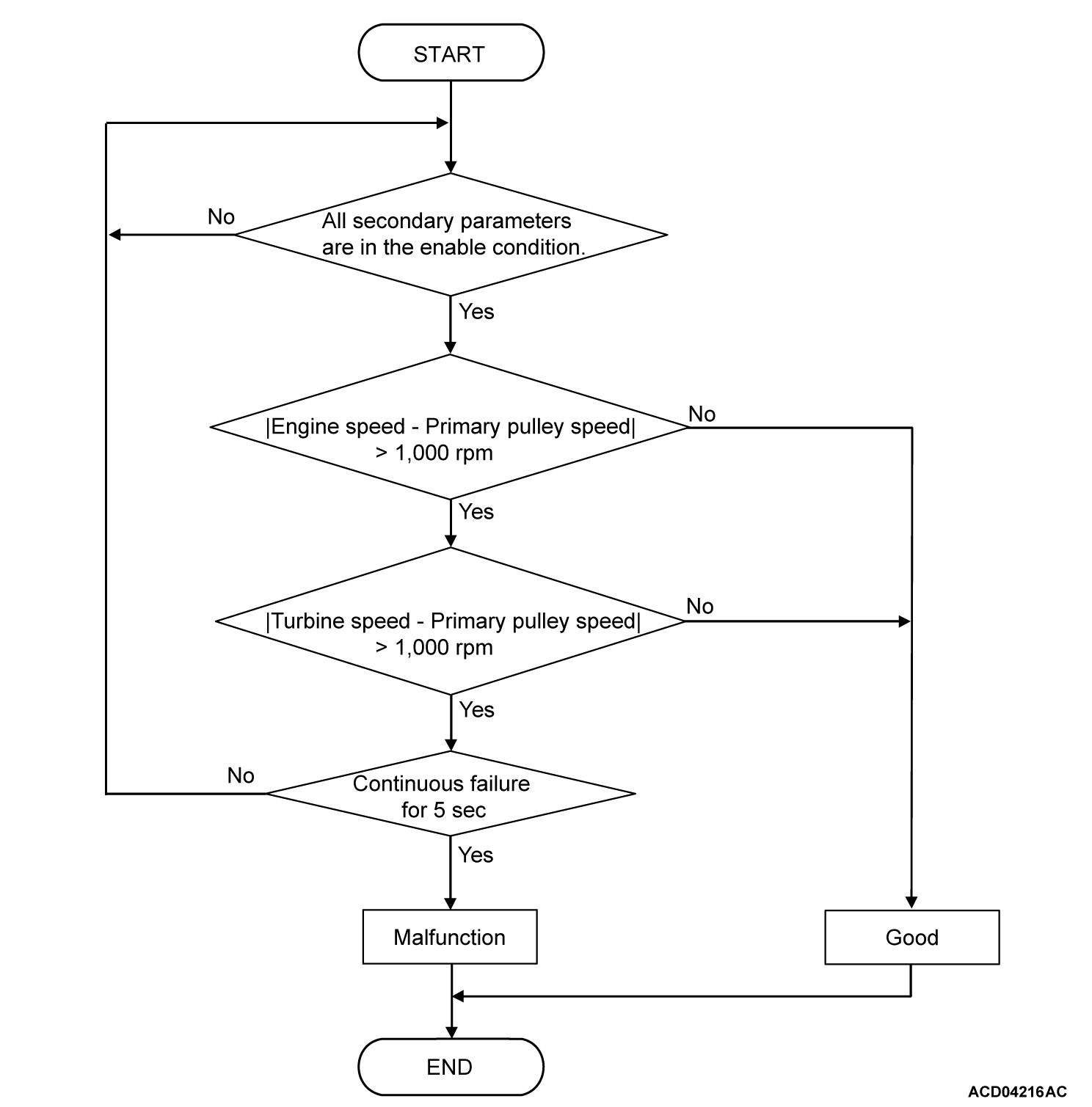

Check Conditions <Input Other Rationality>

- Voltage of battery: 10 volts or more.

- Transmission range switch position: D.

- Engine speed: 450 r/min or more.

- Primary pulley speed: 300 r/min or more.

- Secondary pulley speed: 300 r/min or more.

- Turbine speed: 300 r/min or more.

- Turbine speed - Engine speed: 1,000 r/min or less.

- Torque converter clutch status: Engaged.

Judgment Criteria <Input Rationality-Low (Open/Low revolution)>

- Primary pulley speed [Secondary pulley speed: 500 r/min or more]: Less than 150 r/min. (5 seconds)

Judgment Criteria <Input Open Circuit>

- Primary pulley speed [Primary pulley speed at 10 millisecond before: 1,000 r/min or more]: 200 r/min or less. (0.5 second)

Judgment Criteria <Input Other Rationality>

- Engine speed - Primary pulley speed: More than 1,000 r/min. (5 seconds)

- Turbine speed - Primary pulley speed: More than 1,000 r/min. (5 seconds)

OBD-II DRIVE CYCLE PATTERN

Transmission range: D (Drive the vehicle for 10 seconds or more while the accelerator opening angle is 20% or more)

PROBABLE CAUSES

- Malfunction of primary pulley speed sensor

- Damaged wiring harness and connectors

- Malfunction of TCM

DIAGNOSIS

STEP 1. Check for open circuit in ground line between the primary pulley speed sensor connector (terminal No. 3) and body ground

STEP 2. Voltage measurement at primary pulley speed sensor connector (terminal No. 1)

(1) Disconnect the primary pulley speed sensor connector, and measure at the wiring harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between the primary pulley speed sensor connector (terminal No. 1) and body ground.

OK: 10 V or more

Is the check result normal?

: Repair the connector(s) or the wiring harness (power supply line between the primary pulley speed sensor connector terminal No. 1 and the CVT control relay connector).

STEP 3. Check for open circuit or short to ground in PRMS line between the primary pulley speed sensor connector and the TCM connector

STEP 4. Measure the output wave pattern of the primary pulley speed sensor at TCM connector (PRMS terminal).

(1) Connect the primary pulley speed sensor connector and TCM connector.

(2) Selector lever position: L.

(3) Drive at a constant speed of approx. 20 km/h (13 mph).

(4) Connect an oscilloscope, and measure the voltage between TCM connector PRMS terminal and body ground.

Is the check result normal?

Visually check the tip of the primary pulley speed sensor for deposits or damage, and repair or replace it if necessary.

Visually check the tip of the primary pulley speed sensor for deposits or damage, and repair or replace it if necessary.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)