DTC P0016: Crankshaft/Camshaft Position Sensor Phase Problem

TECHNICAL DESCRIPTION

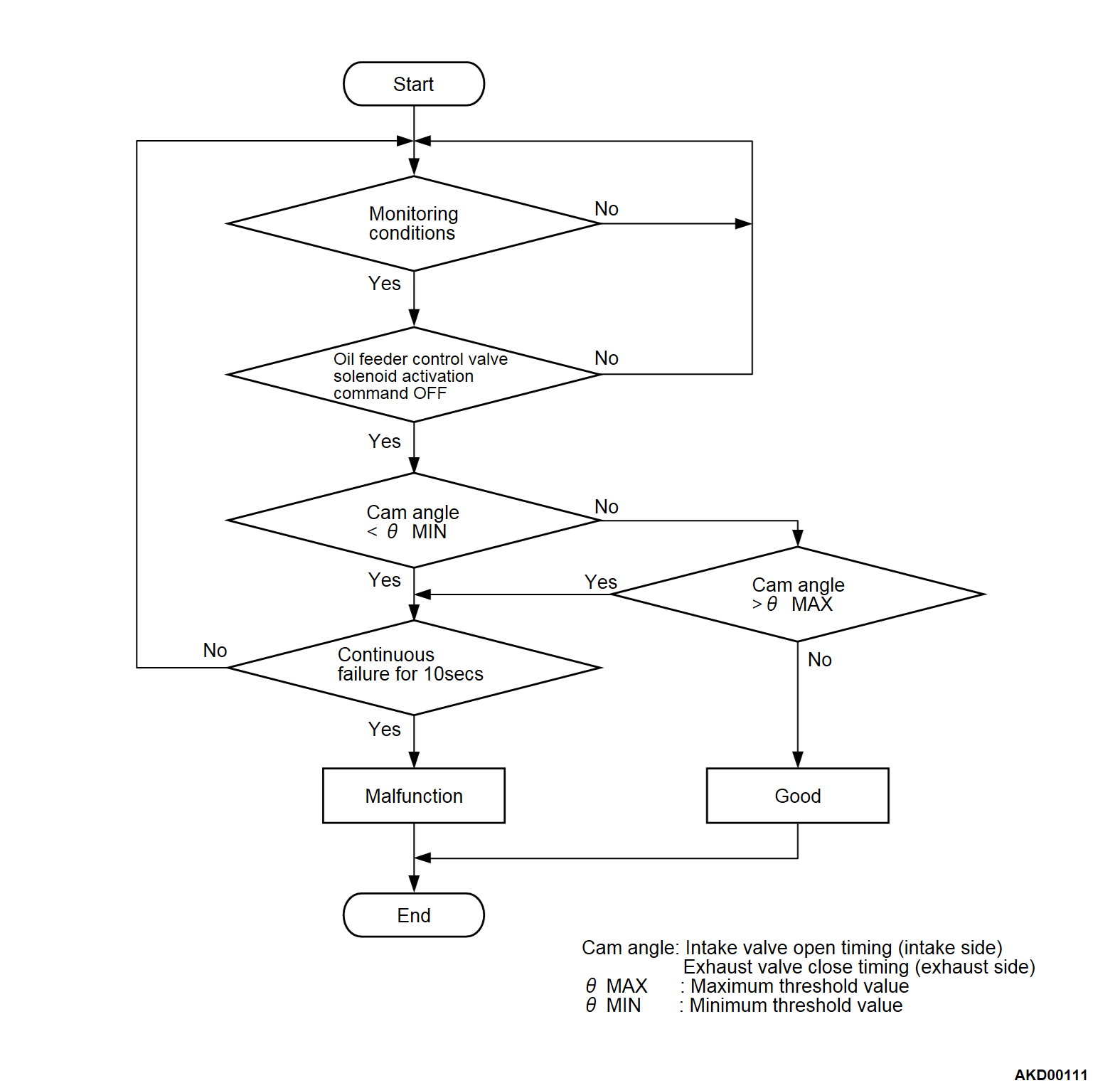

- The ECM checks the MIVEC system for malfunction.

DESCRIPTIONS OF MONITOR METHODS

- The open timing of the intake valve is faster or slower than the specified value.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Camshaft position sensor

- Mass airflow sensor

- Engine coolant temperature sensor

- Throttle position sensor

- Injection valve

DTC SET CONDITIONS

Check Conditions

- Engine speed is between 594 r/min and 1,500 r/min.

- Engine coolant temperature is between 20°C (68°F) and 88°C (190°F).

- 1 second has elapsed after the above mentions have been met.

Judgment Criterion

- The open timing of the intake valve is faster than -7.3 degrees (ATDC) for 10 seconds.

or

- The open timing of the intake valve is slower than 8.2 degrees (ATDC) for 10 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are: )

- Timing belt in out of place.

- Loose timing belt.

- ECM failed.

DIAGNOSIS

Required Special Tools

- MB991709: Test Harness

- MB992110: Power Plant ECU Check Harness

STEP 1. Using the oscilloscope, measure output wave pattern at crankshaft position sensor and camshaft position sensor.

(1) Disconnect the crankshaft position sensor connector and connect the test harness special tool (MB991709) between the separated connectors.

(2) Connect the oscilloscope probe to the crankshaft position sensor side connector terminal SGT line.

(3) Disconnect the camshaft position sensor connector, and connect test harness special tool (MB991709) between the separated connectors.

(4) Connect the oscilloscope probe to the camshaft position sensor side connector terminal SGC line.

| note | When measuring with the ECM side connector, disconnect all ECM connectors. Connect the check harness special tool (MB992110) between the separated connectors. Then connect the oscilloscope probe to the check harness connector terminal SGT (crankshaft position sensor) and terminal SGC (camshaft position sensor). |

(5) Start the engine and run at idle.

(6) Check the waveform.

(7) Turn the ignition switch to the "LOCK" (OFF) position.

Is the waveform normal?

STEP 2. Check the trouble symptoms.

(1) Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 25  .

.

.

.(2) Check the diagnostic trouble code (DTC).

Is DTC P0016 set?

STEP 3. Check timing mark on the timing belt.

Is timing belt in out of place?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)