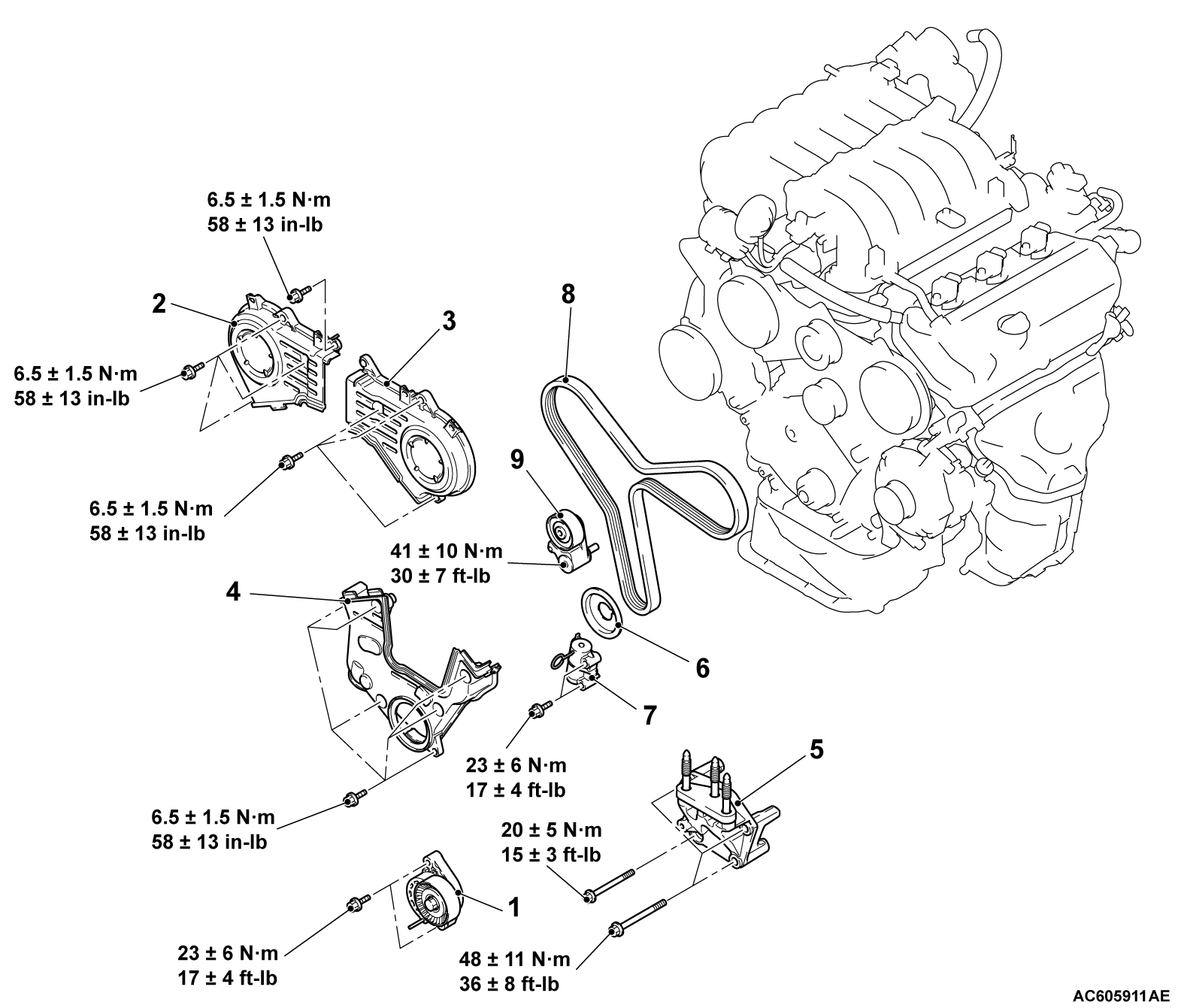

REMOVAL AND INSTALLATION

Pre-removal operation | Post-installation operation |

Required Special Tools:

- MB990767: Front Hub and Flange Yoke Holder

- MD998716: Crankshaft Wrench

- MD998719: Pin

REMOVAL SERVICE POINTS

<<A>> TIMING BELT AUTO-TENSIONER REMOVAL

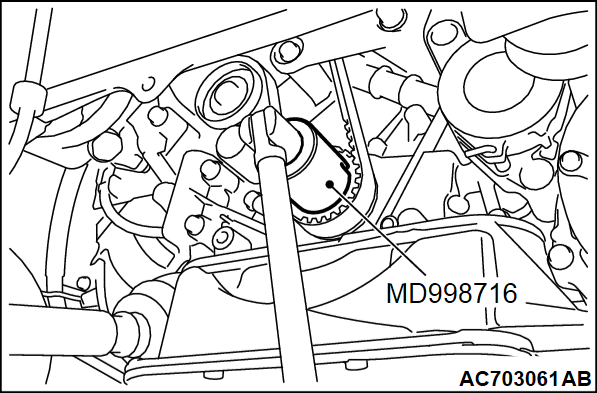

1.

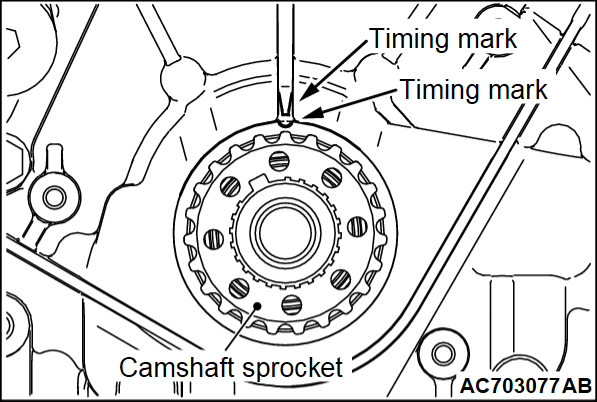

Use special tool MD998716 to turn the crankshaft clockwise to align each timing mark and to set the No. 1 cylinder to compression top dead center.

| caution | Never turn the crankshaft counterclockwise. |

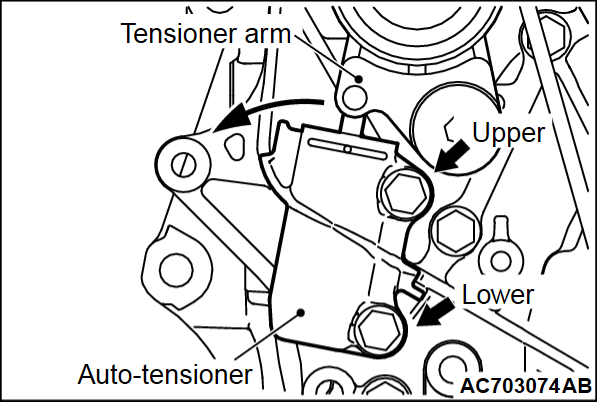

2. Remove the upper mounting bolt of the timing belt auto-tensioner.

3.

| caution | The timing belt auto-tensioner rotates centering on the flange bolt due to the rod thrust, so please make sure your finger is not trapped. |

Loosen the lower mounting bolt of the timing belt auto-tensioner slowly and slide the timing belt auto-tensioner slightly. Remove the rod from the tensioner arm.

4. Remove the lower mounting bolt of the timing belt auto-tensioner.

INSTALLATION SERVICE POINT

>>A<< TIMING BELT/TIMING BELT AUTO-TENSIONER INSTALLATION

| caution | Always bleed the timing belt auto-tensioner of air before installing the timing belt auto-tensioner (Refer to  ). ). |

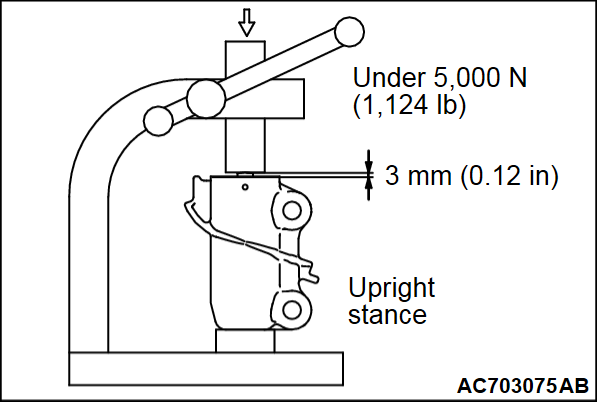

1. Insert the pin into the rod of the auto-tensioner under the following procedures.

(1)

| caution | Notable factors for inserting pin

|

Put the auto-tensioner vertically to the vertical press not to be in the sideways direction.

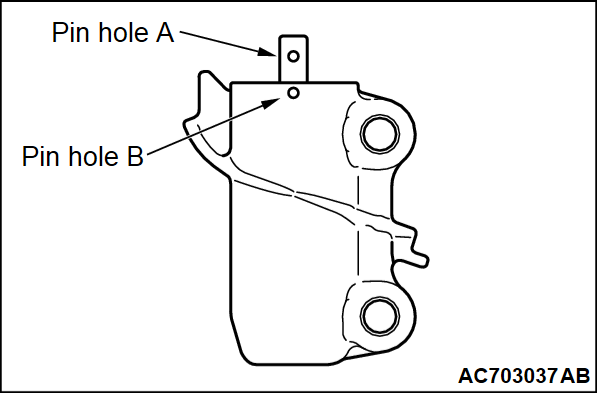

(2) Slowly close the vice to force the rod in until the hole (A) of the rod is lined up with set hole (B) of the cylinder.

(3) Insert a pin into the set holes.

(4) Remove the timing belt auto-tensioner from the vice.

2. Install the timing belt auto-tensioner with the setting pin, and tighten the mounting bolts to the specified torque.

Tightening torque: 23 ± 6 N·m (17 ± 4 ft-lb)

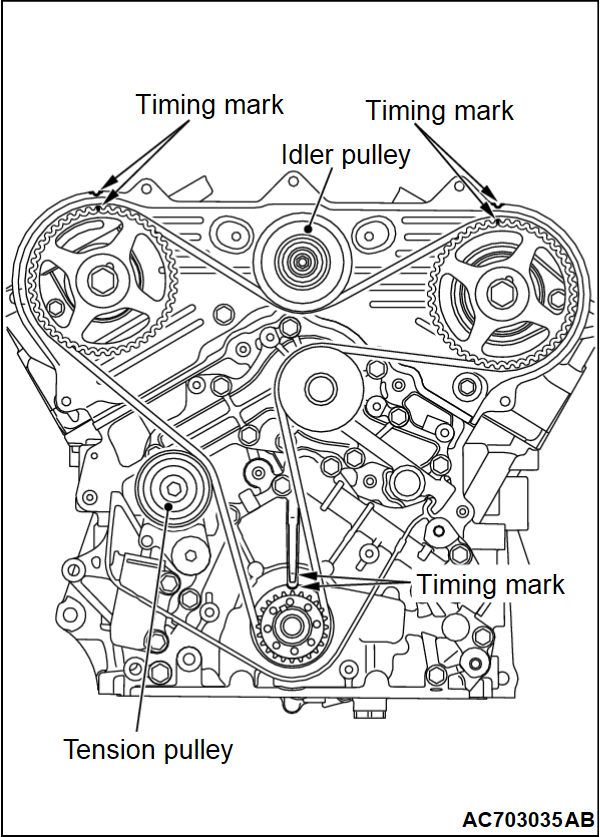

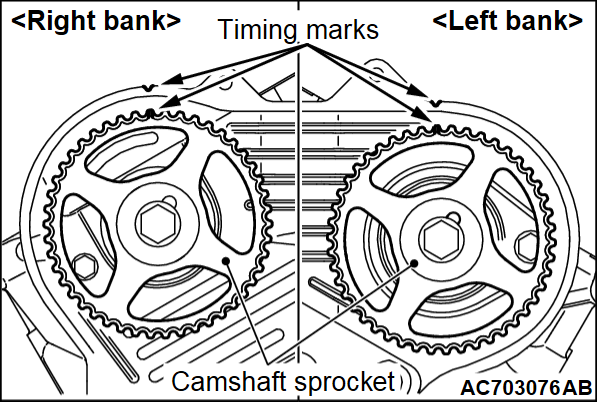

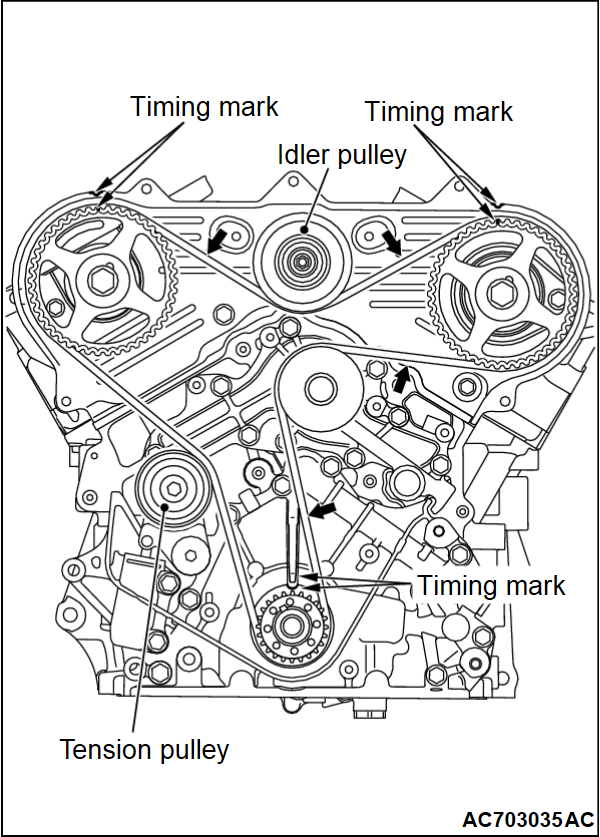

3. Align the timing marks on the camshaft sprockets with those on the timing belt rear cover and the timing mark on the crankshaft sprocket with that on the engine block as shown in the illustration.

4.

Install the timing belt by the following procedure so that there is no deflection in the timing belt between each sprocket and pulley.

| caution | The camshaft sprocket (right bank) can turn easily due to the spring force applied, so be careful not to get your fingers caught. |

(1) Crankshaft sprocket

(2) Water pump pulley

(3) Camshaft sprocket (Left bank)

(4) Idler pulley

(5) Camshaft sprocket (Right bank)

(6) Tensioner pulley

5. Apply the force to the camshaft sprocket (Right bank) counterclockwise until the tension side of timing belt is tight. Check all the timing marks again.

6. Remove the setting pin that has been inserted into the auto-tensioner.

7. Turn the crankshaft clockwise twice to align the timing marks.

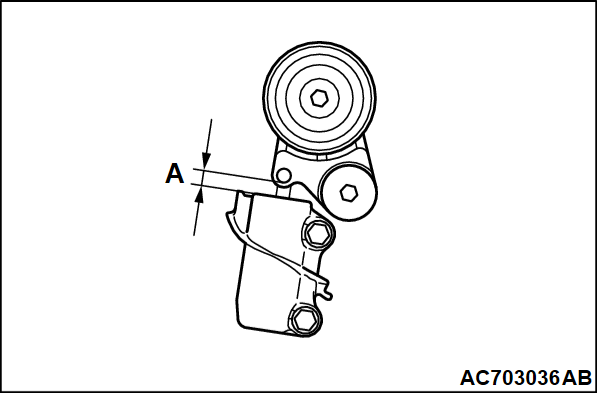

8. Wait for at least five minutes, then check that the auto-tensioner push rod extends within the standard value range.

Standard value (A): 9.1 - 13.4 mm (0.36 - 0.52 inch)

9. If not, repeat the operation in steps 1 to 8 above.

10. Check again that the timing marks of the sprockets are aligned.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)