DTC P226C: Turbocharger Wastegate Actuator Control Slow Response

CIRCUIT OPERATION

TECHNICAL DESCRIPTION

In response to a signal from the turbocharger wastegate position sensor, the ECM controls the turbocharger wastegate actuator control motor.

DESCRIPTIONS OF MONITOR METHODS

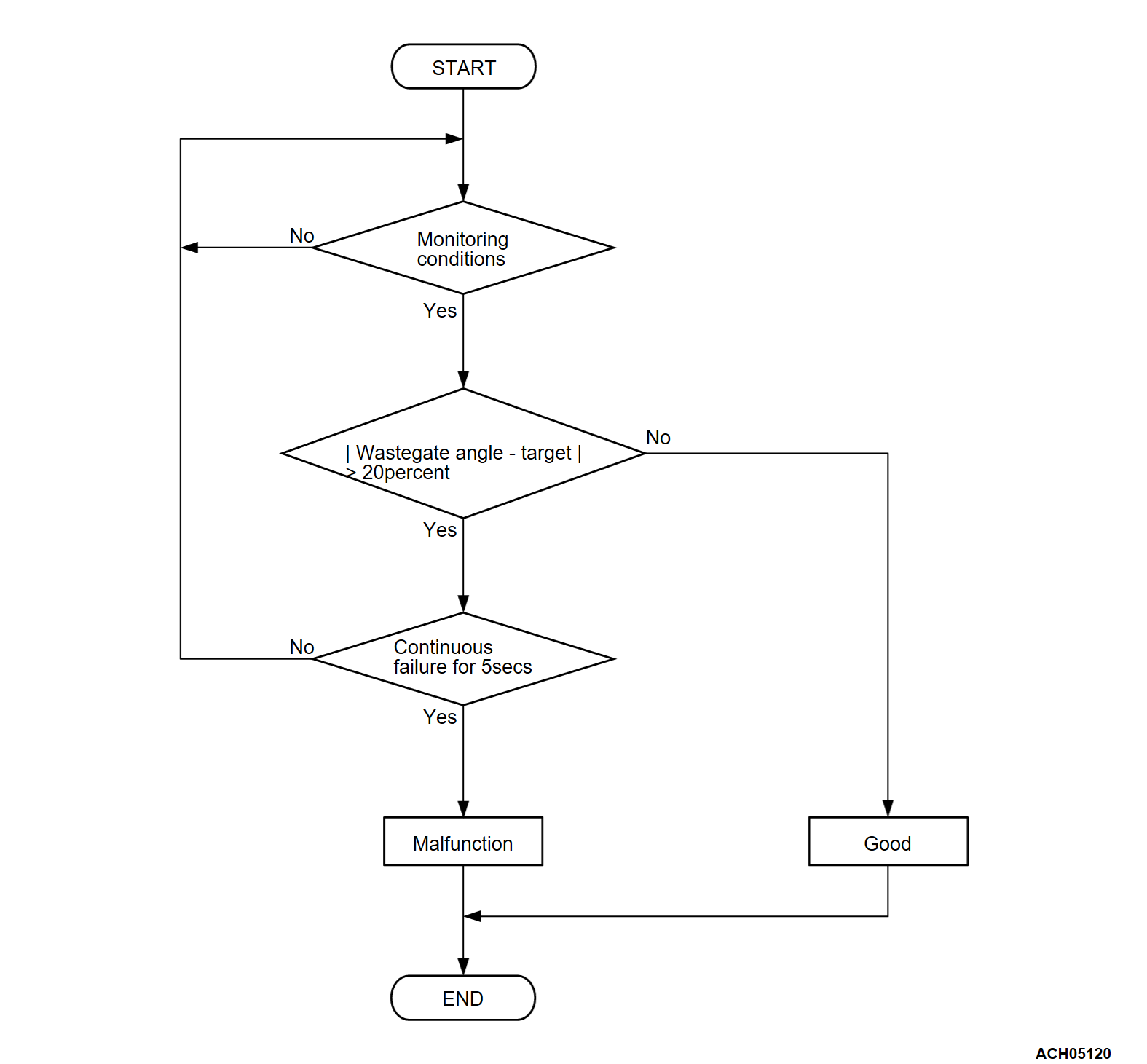

Difference between actual turbocharger wastegate position angle and target turbocharger wastegate position angle is greater than the specified value.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- 2 seconds or more have passed since the engine starting sequence was completed.

- Battery positive voltage is between 9 and 16 volts.

- Turbocharger wastegate position sensor output voltage is 4.2 volts or less. Or, target turbocharger wastegate regulating valve opening is 69 percent or less.

Judgment Criterion

- Difference between actual turbocharger wastegate position angle and target turbocharger wastegate position angle is more than 20 percent for 5 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Stop driving the turbocharger wastegate actuator control motor.

- Torque is restricted.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are: )

- Turbocharger assembly failed.

- Turbocharger wastegate actuator circuit harness damage, or connector damage.

- ECM failed.

DIAGNOSIS

STEP 1. Check of harness damage in WGM+ line between turbocharger wastegate actuator connector and ECM connector.

Is the harness wire in good condition?

STEP 2. Check of harness damage in WGM- line between turbocharger wastegate actuator connector and ECM connector.

Is the harness wire in good condition?

STEP 3. Check of harness damage in WGMG line between ECM connector and ground.

Is the harness wire in good condition?

STEP 4. Check of harness damage in WGP5 line between turbocharger wastegate actuator connector and ECM connector.

Is the harness wire in good condition?

STEP 5. Check of harness damage in WGPS line between turbocharger wastegate actuator connector and ECM connector.

Is the harness wire in good condition?

STEP 6. Check of harness damage in WGPG line between turbocharger wastegate actuator connector and ECM connector.

Is the harness wire in good condition?

STEP 7. Check turbocharger wastegate actuator.

Refer to GROUP 15, On-vehicle Service - Turbocharger Wastegate Actuator Check  .

.

.

.Are there any abnormalities?

STEP 8. Check turbocharger assembly.

(1) Visually check the turbine wheel and the compressor wheel for cracking or other damage.

(2) Check whether the turbine wheel and the compressor wheel can be easily turned by hand.

(3) Check for oil leakage from the turbocharger assembly.

| note | When the wastegate valve is usual, it controls it as follows. Ignition switch "Lock" (OFF) position: Open Ignition switch "ON" position: Close |

Are there any abnormalities?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)